Steel having finely dispersed inclusions

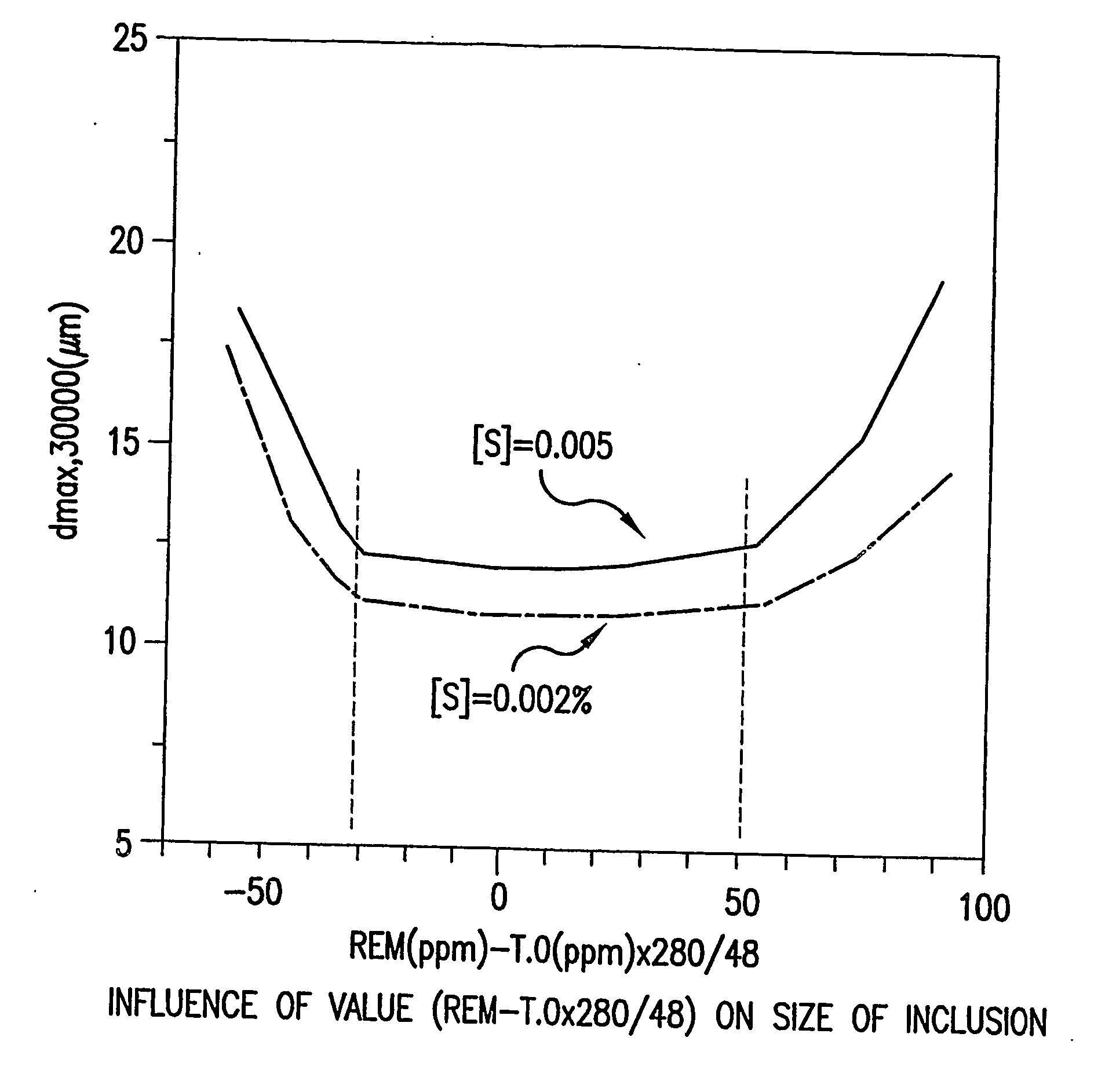

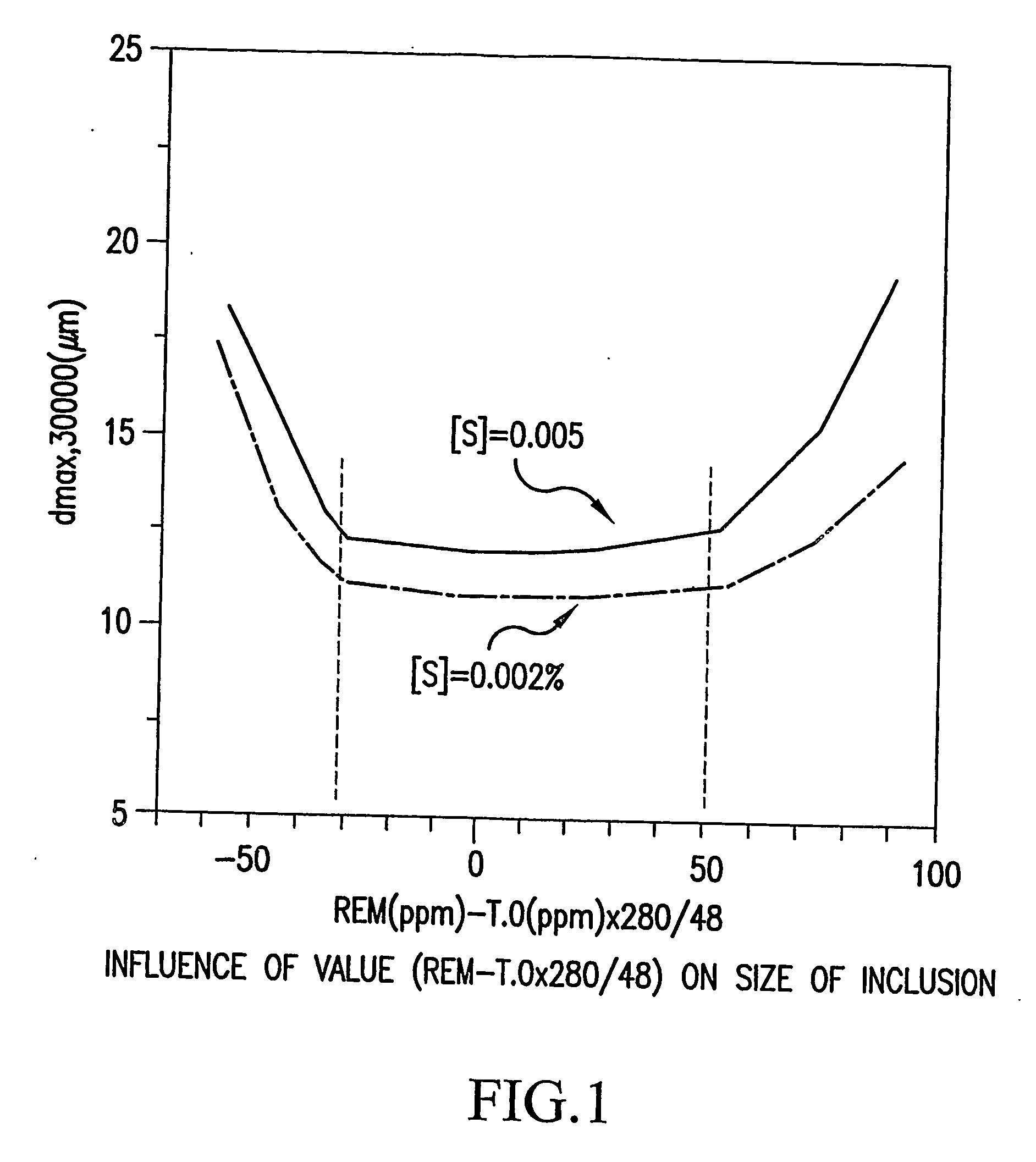

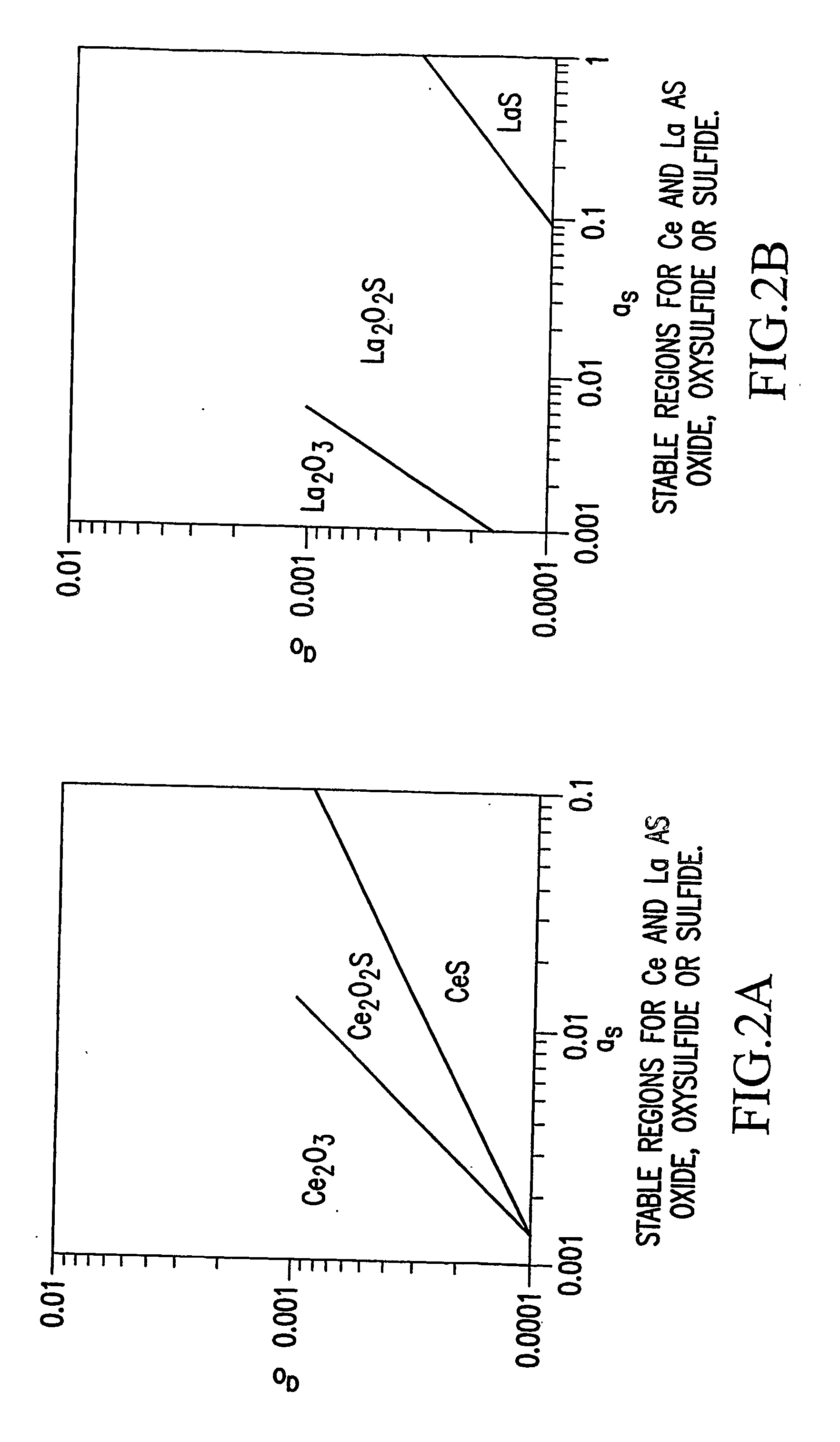

a technology of oxidized inclusions and fine dispersion, which is applied in the direction of shafts, bearings, mechanical equipment, etc., can solve the problems that the above-mentioned methods of eliminating al/sub>2/sub>3/sub>based inclusions are not sufficient to meet the high quality level now in demand, and achieve the effect of easy forming of sulfides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0059] Pig iron discharged from blast furnace had dephosphorization and desulfurization treatment, then 270 tons of the pig iron was transported into the converter for oxygen blowing, and the base molten steel for bearing steel which has prescribed contents of C, P and S was prepared. Al, Si, Mn and Cr were added to the prepared base molten steel while the base molten steel was discharged into a ladle and having Ladle Furnace (LF) and RH vacuum degassing treatment. At LF treatment, a high oxidation degree slag discharged from the converter was reduced to a lower content of iron oxide and MnO, and CaO was added to increase the CaO / SiO2 ratio, by which ingredients causing re-oxidization was reduced. The content of Al2O3 was adjusted to obtain a slag composition which has a high capability of absorbing inclusions. At the RH treatment, dehydrogenation and elimination of inclusions were made. Furthermore, a predetermined amount of REM stored in a hopper located outside on top of the RH v...

example 2

[0063] A bearing steel described in Table 5 was manufactured in the same way as in Example 1.

TABLE 5REMPercentageadditionof theVibra-amount:number:dmax,AcoustictionalChemical composition of bearing steelbformulaformula30000character-character-CSiMnAlSTiT.O.REM(1)(2)(μm)isticisticSamples11.010.230.410.020.0030.00050.00060.0033−20.8711.8⊚⊚of21.000.240.410.020.0020.00050.00060.0077420.9312.3⊚⊚Example31.000.240.400.020.0030.00060.00060.0012−230.8512.1⊚⊚241.020.230.420.0010.0020.00040.00100.004270.9011.5⊚◯50.990.240.410.020.0060.00050.00060.003720.8512.4◯◯Compara-11.020.220.400.020.0030.00050.00060−350.019.2ΔΔtive20.990.240.420.020.0030.00050.00050.0003−320.8117.5ΔΔSamplesa31.000.220.410.020.0030.00040.00060.0110750.9517.3ΔΔ41.010.230.410.020.0020.00050.00060.004050.6516.3ΔΔ51.000.240.420.020.0030.00150.00050.004270.8512.2XX61.010.230.400.020.0030.00040.00060.0045100.9516.8XX

aComparative Samples prepared using the method of Comparative Example 2

bCr: 1.40 ˜ 1.44%, P: 0.0010 ˜ 0.0015%

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| equivalent diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com