In situ membrane-based oxygen enrichment for direct energy conversion methods

a direct energy conversion and oxygen enrichment technology, applied in the direction of indirect carbon-dioxide mitigation, fuel supply regulation, combustion regulation, etc., can solve the problems of difficult to achieve temperature without oxygen enrichment, achieve improved fuel-to-electric efficiency, increase combustion efficiency, and improve combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

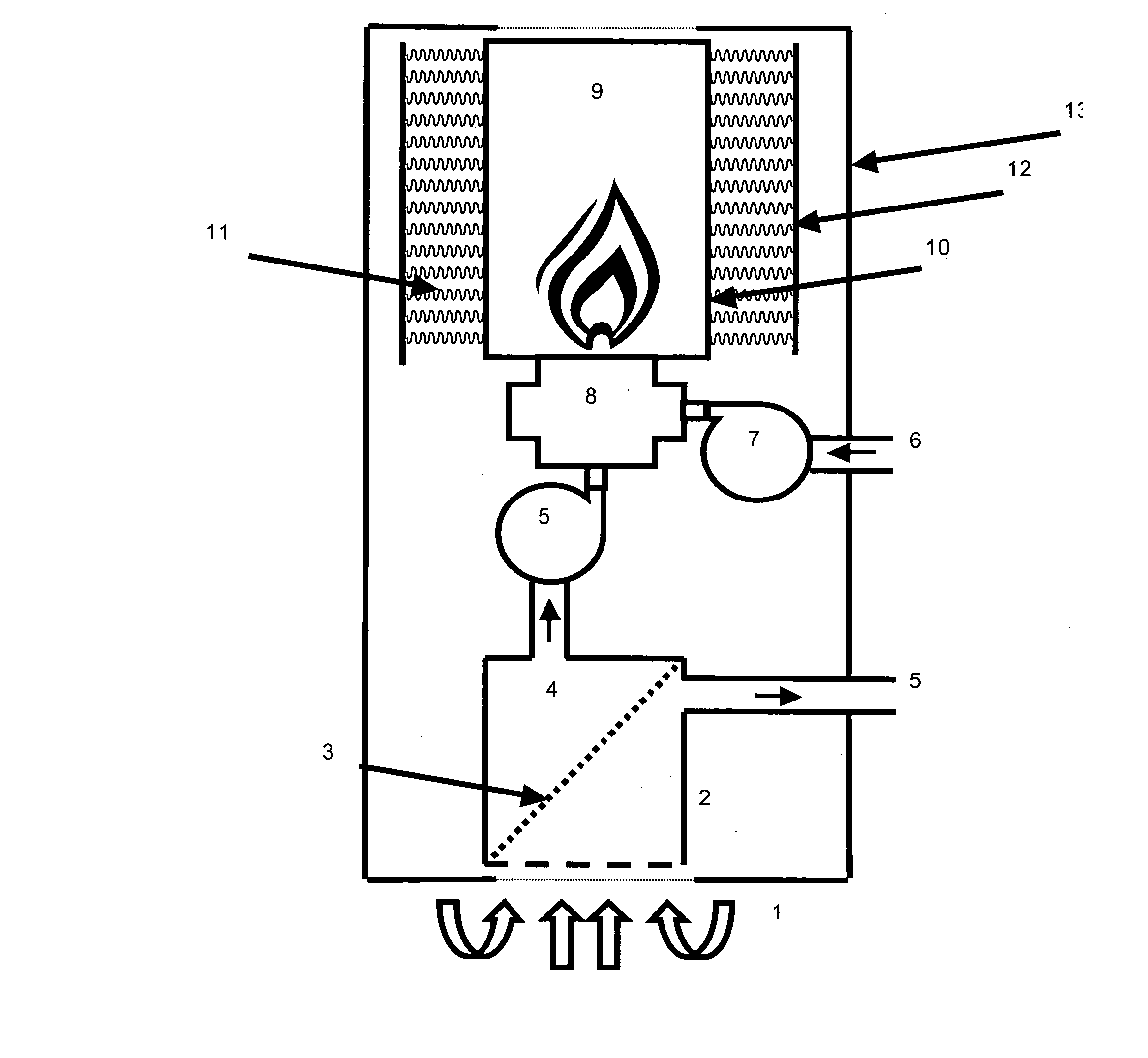

[0019] With reference to FIG. 1, ambient air 1 flows into a membrane apparatus 2, wherein a portion of the flow permeates a membrane 3 as oxygen enriched air 4. Oxygen enriched flow 4 from the membrane apparatus enters an adjustable flow blower / pump 5 where it is fed to a diesel / JP-8 burner assembly 8. Diesel / JP-8 fuel 6 is fed through an adjustable flow fuel pump 7 to the same diesel / JP-8 burner assembly 8. The fuel is ignited in the burner assembly 8. The flame and hot combustion gases flow through the combustion chamber 9 while heating an emitter surface 10. Energy 11 (electromagnetic or electric) is transmitted to surface 12. All components are housed in enclosure 13.

[0020] Though not shown, nitrogen enriched flow 5 from the membrane can be used for cooling the thermophotovoltaic cells, cooling the hot exhaust surfaces, or for other cooling needs.

[0021] Membrane apparatus 2 can consist of a single membrane element or more than one membrane elements configured in series, parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com