Process for reducing nitrogen containing compounds and lignin in tobacco

a technology of nitrogen containing compounds and lignin, which is applied in the field of tobacco smoking materials, can solve the problems of adversely affecting the smoke quality of tobacco, difficult to extract nitrogenous compounds from cured tobacco lamina, stems, fiber cell walls, etc., and achieves the reduction of nitrogen containing pyrolitic products, reducing lignin and nitrogenous content, and improving smokability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

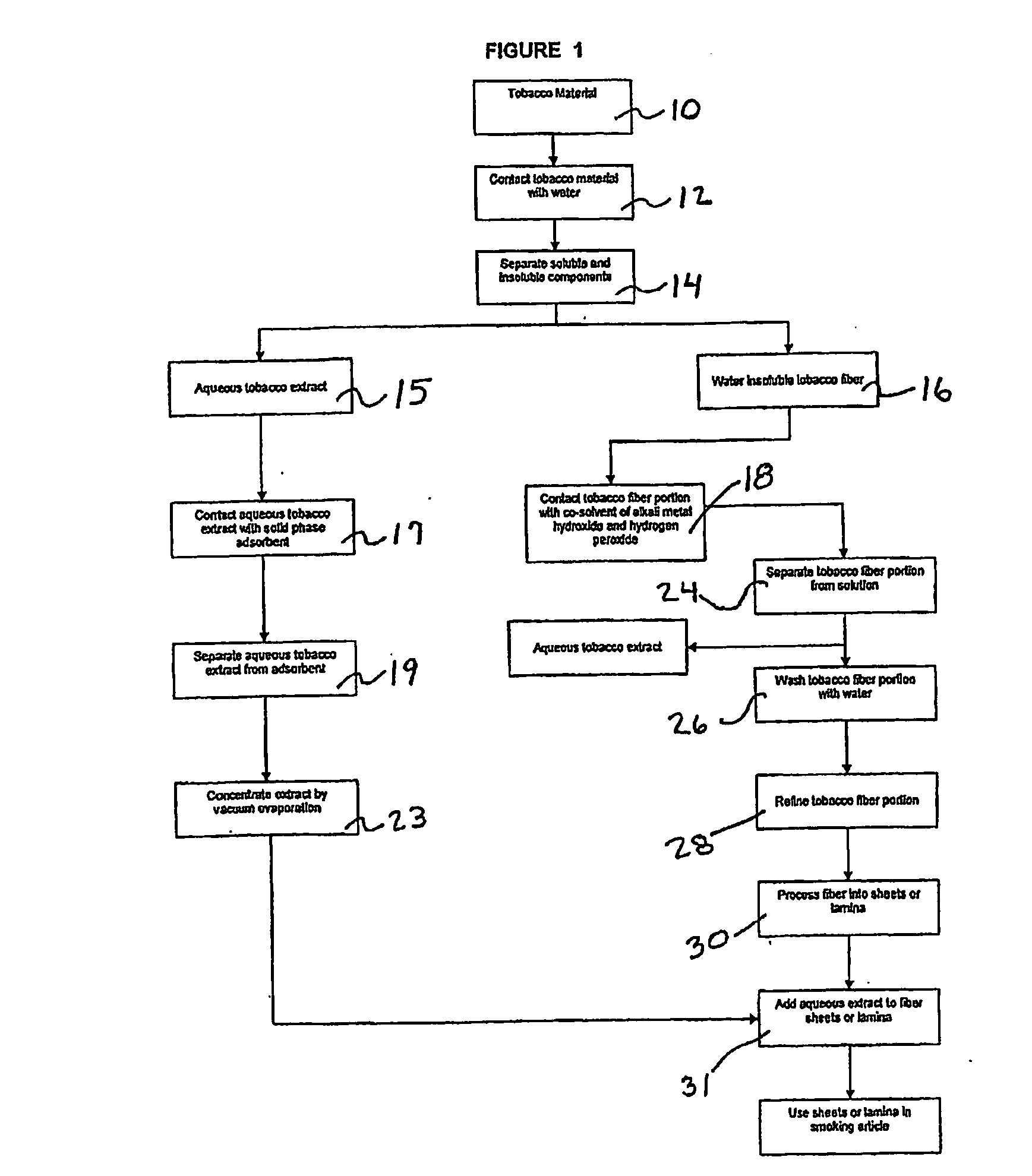

Image

Examples

examples

[0016] For a better understanding of the present invention, the following Examples are incorporated herein to illustrate the present invention with no intention of being unduly limited thereby.

Control 1 and Example 1A, 1B

[0017] A 2.8 kg mixture of tobacco materials, including flue-cured and burley tobacco scraps, stems, laminae and fines having a nitrogen content of 2.09% was extracted with water at 70° C. for 30 minutes to 120 minutes as known in the art. Following centrifugation, the liquid extract was further treated with adsorbent (e.g. diatomaceous clay, activated charcoal, clyodextrin, or combinations thereof or absorbent (cellulose acetate) to remove nitrogenous compounds, and then concentrated by vacuum evaporation. The resultant washed fiber was further extracted to remove lignin and nitrogenous compounds, as mentioned below. From the washed fibers, 350 g portions were then loaded into vessel containing 2.8-4.2 L of an alkaline-peroxide solution, comprising 2.5% (w / w) sod...

examples 2a , 2

Examples 2A, 2B

[0018] These examples were carried out in a similar manner and with the same quantities of materials as in Examples 1A, 1B, except that tobacco materials in alkaline-peroxide solutions were heated to 90° C. and held for 1 h with agitation. Another exception was that one solution contained 4.2% (w / w) sodium hydroxide and 8.3% (w / w) hydrogen peroxide, while another contained 8.3% hydrogen peroxide only. The resulting fiber from the alkaline-peroxide extraction had a 30.5% reduction in lignin and a 62.8% reduction in Kjeldahl nitrogen, while the peroxide extracted fiber had a 18.6% and 20.9% reduction in lignin and Kjeldahl nitrogen, respectively.

examples 3a , 3

Examples 3A, 3B

[0019] These examples were carried out in a similar manner and with the same quantities of materials as in Examples 1A, 1B, the only changes being that tobacco materials and solutions were heated to 120° C. and held for 30 minutes. Another change was that one solution contained 2.5% sodium hydroxide and 7.5% hydrogen peroxide, while another solution contained 8.3% sodium hydroxide only. The fibrous materials from the hydroxide treatment gave a 14.5% reduction in lignin and 85.5% reduction in nitrogen, whereas the alkaline-peroxide treatment gave a 21.8% and 56.2% reduction in lignin and nitrogen content, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com