Heat shielding materials for use in agricultural and horticultural facilities

a technology for horticultural facilities and heat shielding materials, applied in the directions of transportation and packaging, greenhouse cultivation, synthetic resin layered products, etc., can solve the problems of liable deformation, poor weather resistance of coloring matter and copper proposed in the above-cited publications, and rare availability of film- or board-like materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

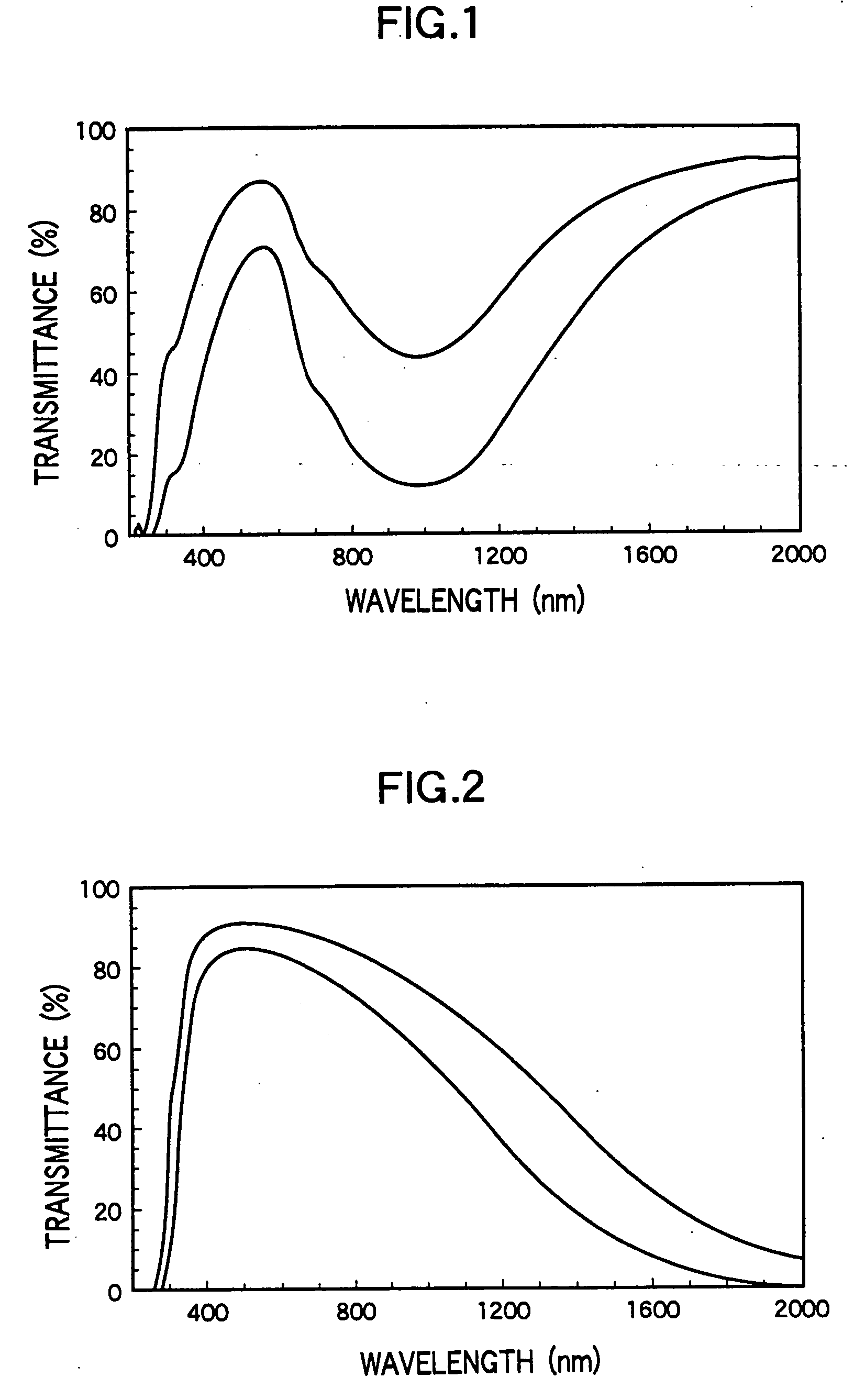

[0047] 20 Parts by weight of LaB6 microparticles (specific surface area: 30 m2 / g), 75 parts by weight of toluene, and 5 parts by weight of a dispersing agent were mixed, followed by dispersion treatment of the mixture, thereby preparing a dispersion A with a dispersed particle diameter of 80 nm on average. Solvent components were relieved from this dispersion A at 50° C. with a vacuum dryer, and dispersion-treated LaB6 was taken as a particle A. The dispersed particle diameter on average was determined by measurement with a measuring apparatus designed to use a dynamic light scattering technique (manufactured by Ohtsuka Electronics Co., Ltd.: ELS-800) and then by averaging the measurements.

[0048] 0.01 Kg of this particle A of LaB6, and 8.7 kg of an ETFE (tetrafluoroethylene-ethylene copolymer) resin were dry-mixed in a V-blender. Then, internal mixing was thoroughly effected at 320° C., i.e., in the neighborhood of the melting temperature of the ETFE resin, followed by extrusion mo...

example 2

[0052] 0.005 Kg of the particle A of LaB6 according to Example 1, and 8.7 kg of an ETFE resin were dry-mixed in a V-blender. Then, as in Example 1, internal mixing was thoroughly effected at 320° C., i.e., in the neighborhood of the melting temperature of the ETFE resin, followed by extrusion molding of the mixture at 320° C., thereby forming a film having a thickness of about 50 μm. The content of LaB6 microparticles in this film is equal to 0.05 g / m2.

[0053] The film-like heat shielding material thus obtained was evaluated as in Example 1. The material reveals a visible light transmission of 80% and a solar radiation transmittance of 65%. It has now been found that the material can sufficiently transmit the light in a visible light region, and concurrently, can screen 35% of direct incident light from sunrays, thus achieving a high level of heat shielding effect. The transmittances in an ultraviolet region are 34% at a wavelength of 290 nm and 43% at a wavelength of 320 nm, and th...

example 3

[0054] As in Example 2 except that a PET (polyethylene terephthalate) resin was used in place of the ETFE resin, and the heating temperature was set at a temperature (about 300° C.) at which the PET resin softened thoroughly, a film was formed by the same method as used in Example 2. The content of LaB6 microparticles in this film is equal to 0.05 g / m2 as is the case with Example 2.

[0055] The film-like heat shielding material thus obtained was evaluated as in Example 1. The material reveals a visible light transmission of 79% and a solar radiation transmittance of 65%. It has now been found that the material can sufficiently transmit the light in a visible light region, and concurrently, can screen 35% of direct incident light from sunrays, thus achieving a high level of heat shielding effect. In addition, the transmittances in an ultraviolet region are 0% at a wavelength of 290 nm and 35% at a wavelength of 320 nm. The transmittance of 0% read at 290 nm is attributable to the cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com