Compressor oil recovering apparatus and multi-unit air conditioner equiped with the same

a compressor oil recovery and multi-unit technology, applied in the field of compressor oil recovery apparatus and multi-unit air conditioners equipped with the same, can solve the problems of compressor reliability degradation, compressor abrasion and performance degradation, compressor oil shortage, etc., to achieve smooth re-supplying, enhance the reliability of the compressor, and enhance the performance of the air conditioner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

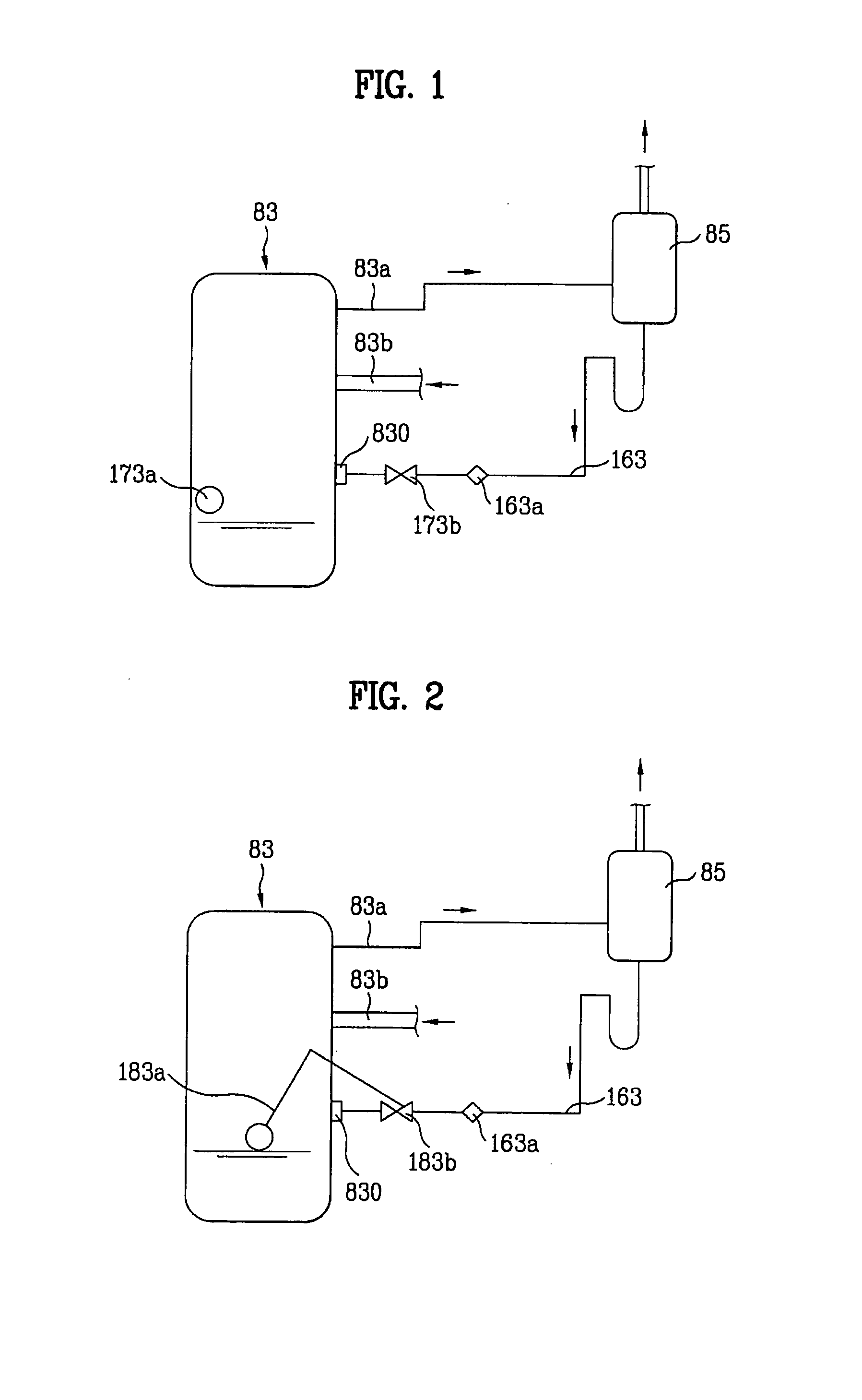

[0041] First, a compressor oil recovering apparatus according to the present invention will be described with reference to FIG. 1.

[0042] As shown in FIG. 1, the compressor oil recovering apparatus according to the first embodiment of the present invention includes a compressor 83, which is included in an air conditioner, an oil separator 85 for separating oil from a refrigerant discharged from the compressor 83, and an oil recovering port 830 provided at the compressor 83.

[0043] The compressor oil recovering apparatus also includes an oil recovering tube 163 having one end connected to the oil separator 85, and the other end connected to the oil recovering port 830.

[0044] The connection of the oil recovering port 830 is achieved at positions where oil recovered through the oil recovering tube 163 does not interfere with refrigerant flows respectively sucked along a refrigerant suction tube 83b of the compressor 83 and discharged along a refrigerant discharge line 83a of the compre...

second embodiment

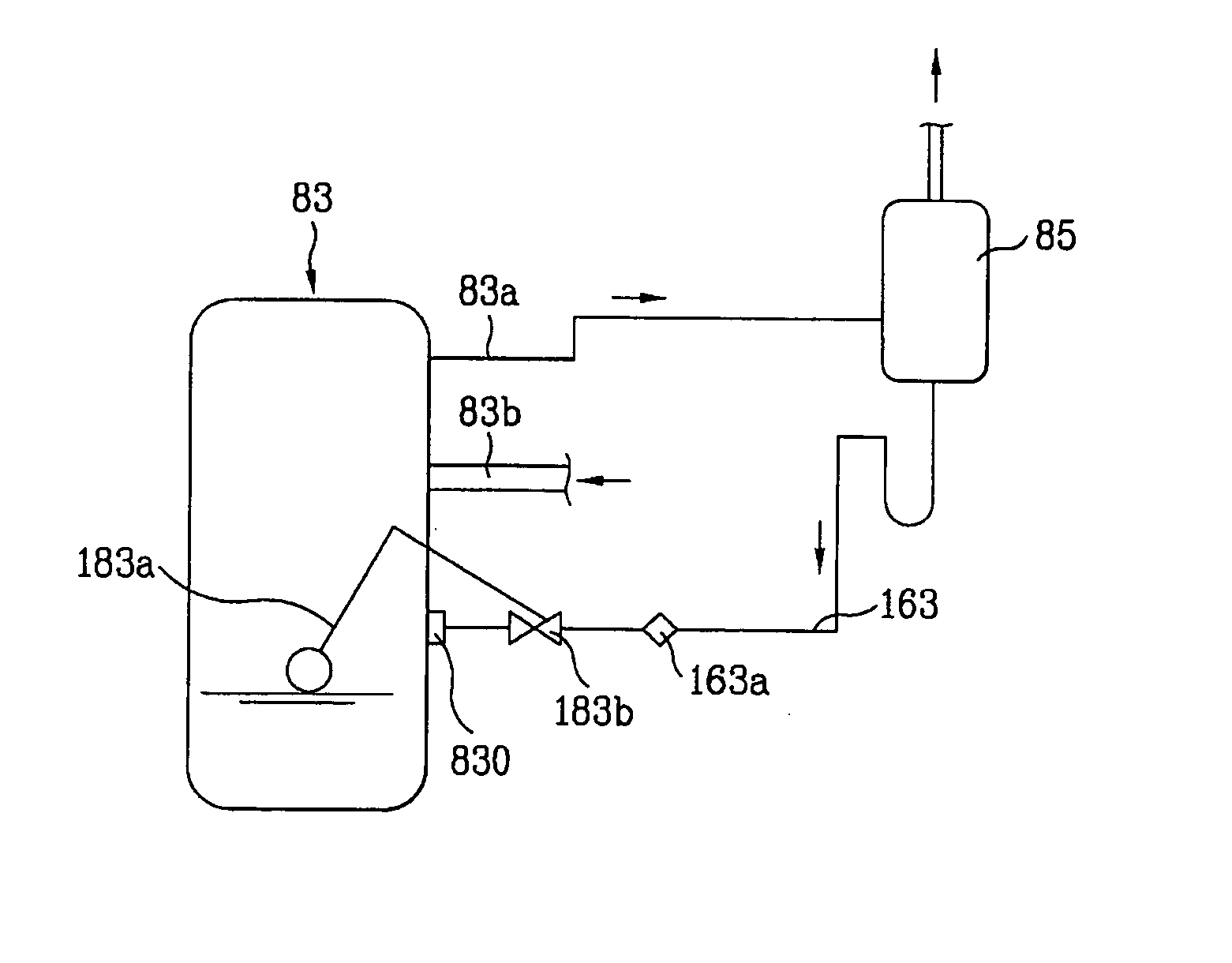

[0053] Next, a compressor oil recovering apparatus according to the present invention will be described with reference to FIG. 2.

[0054] As shown in FIG. 2, the compressor oil recovering apparatus according to the second embodiment of the present invention includes a compressor 83, an oil separator 85, an oil recovering port 830, an oil recovering tube 163, a strainer 163a, and an adjuster, identically to the above-described first embodiment.

[0055] Contrary to the first embodiment, however, the adjuster of the second embodiment includes a float 183a adapted to sense the level of oil stored in the compressor 83, and a float valve 183b for controlling the supply or cut-off of the oil supplied to the compressor 83, and the amount of the supplied oil in accordance with the oil level sensed by the float 183a. The float valve 183b is arranged at the oil recovering tube 163.

[0056] Similarly to the first embodiment, in accordance with the second embodiment, it is possible to not only suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com