Generator motor device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A mode for carrying out the present invention is explained below with reference to an embodiment of the present invention shown in the attached drawings.

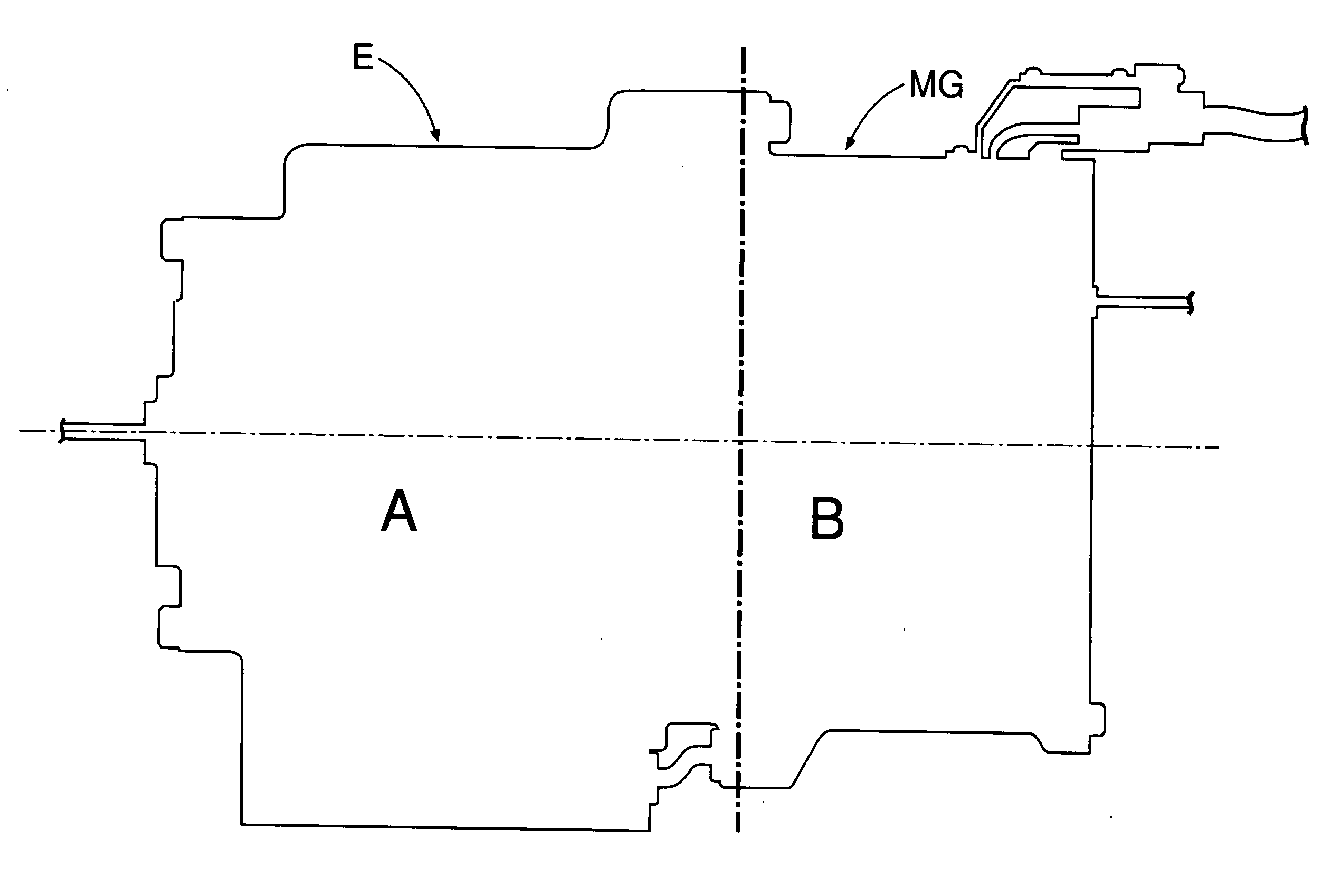

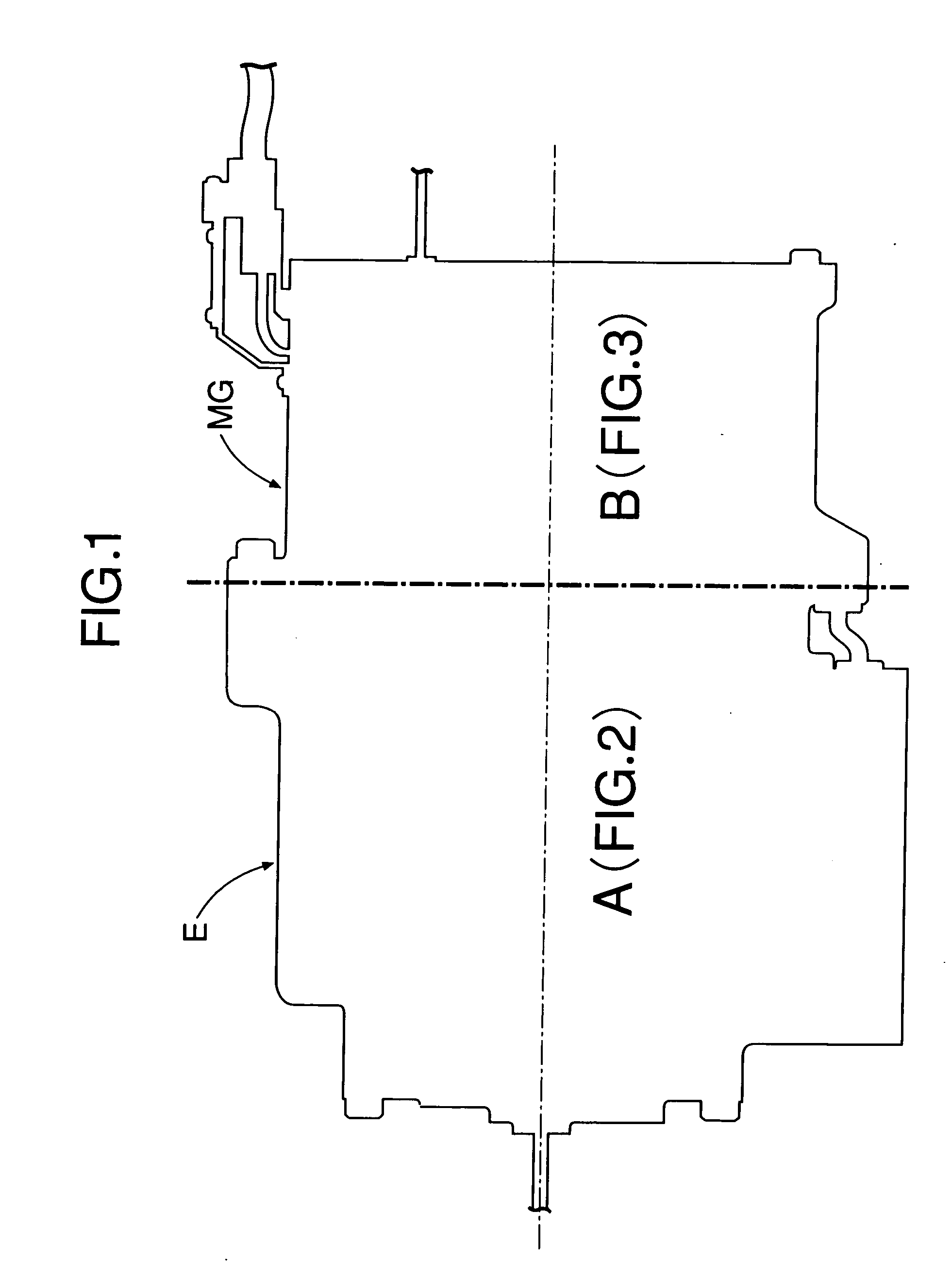

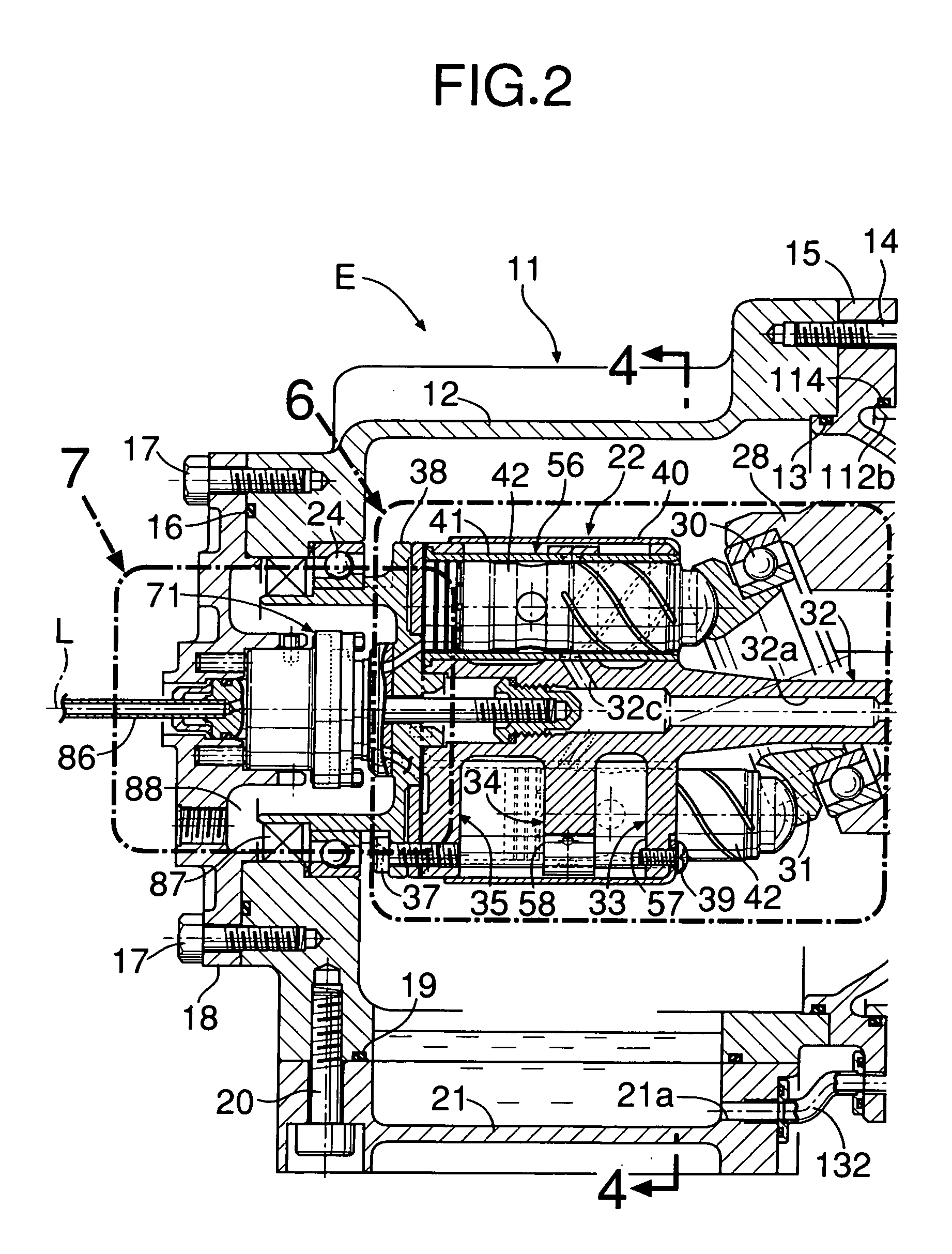

[0036]FIG. 1 to FIG. 15 show one embodiment of the present invention.

[0037] As shown in FIG. 1 to FIG. 11, an expander E of this embodiment is used in, for example, a Rankine cycle system, and outputs mechanical work by adiabatic expansion of high temperature, high pressure steam as a working medium. A casing 11 of the expander E is formed from a casing main body 12, a front cover 15 joined via a seal 13 to a front opening of the casing main body 12 by a plurality of bolts 14, a rear cover 18 joined via a seal 16 to a rear opening of the casing main body 12 by a plurality of bolts 17, an oil pan 21 joined via a seal 19 to a lower opening of the casing main body 12 by a plurality of bolts 20, a pump housing 102 joined to a front face of the front cover 15 by a plurality of bolts 101, and a pump cover 104 joined to a front fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com