Turbine engine shroud segment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

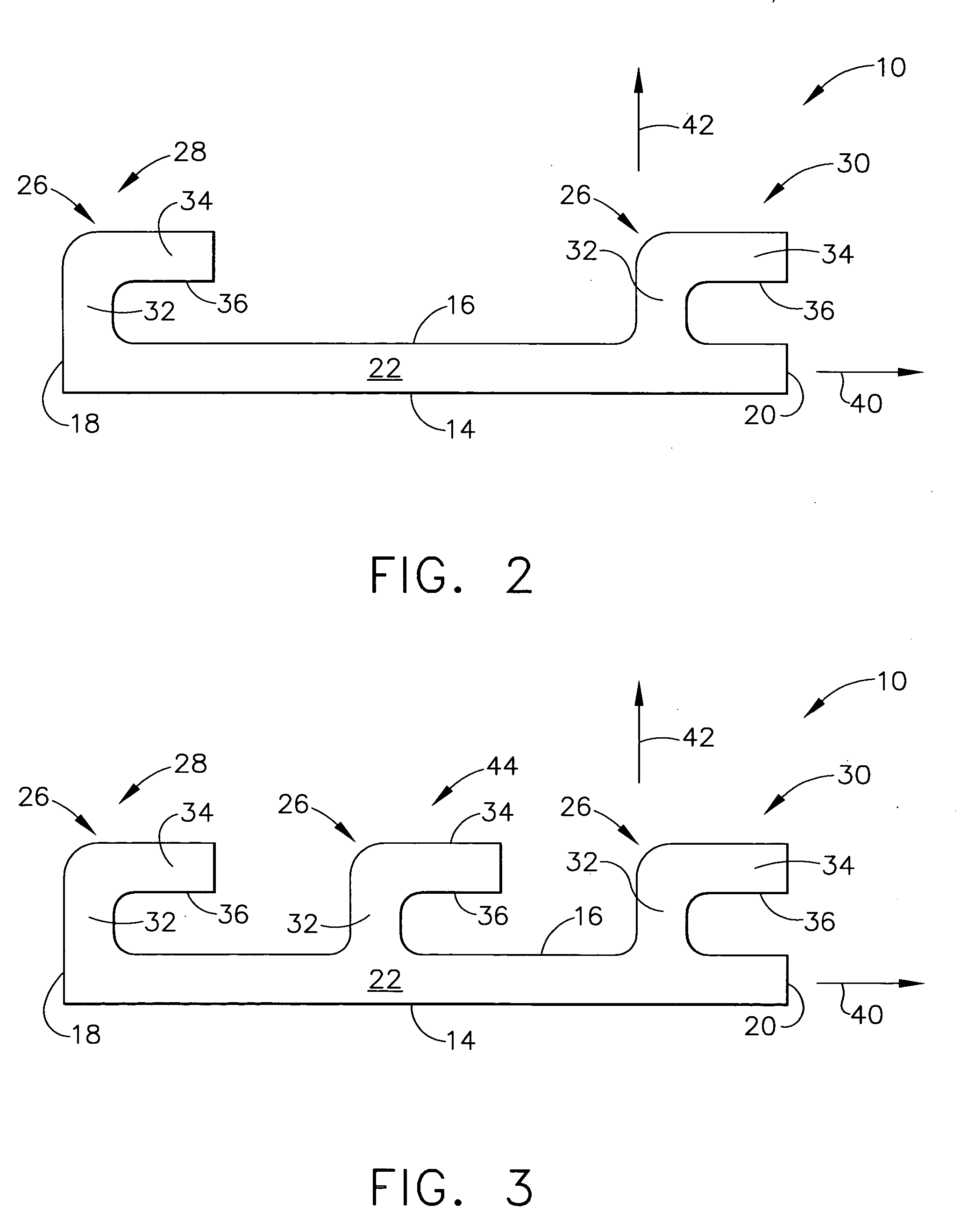

[0019] The present invention will be described in connection with an axial flow gas turbine engine for example of the general type shown and described in the above identified Proctor et al patent. Such an engine comprises, in serial flow communication generally from forward to aft, one or more compressors, a combustion section, and one or more turbine sections disposed axisymmetrically about a longitudinal engine axis. Accordingly, as used herein, phrases using the term “axially”, for example “axially forward” and “axially aft”, refer to relative positions or general directions in respect to the engine axis; phrases using forms of the term “circumferential” refer to circumferential position or direction generally about the engine axis; and phrases using forms of the term “radial”, for example “radially inner” and “radially outer”, refer to relative radial position or direction generally from the engine axis.

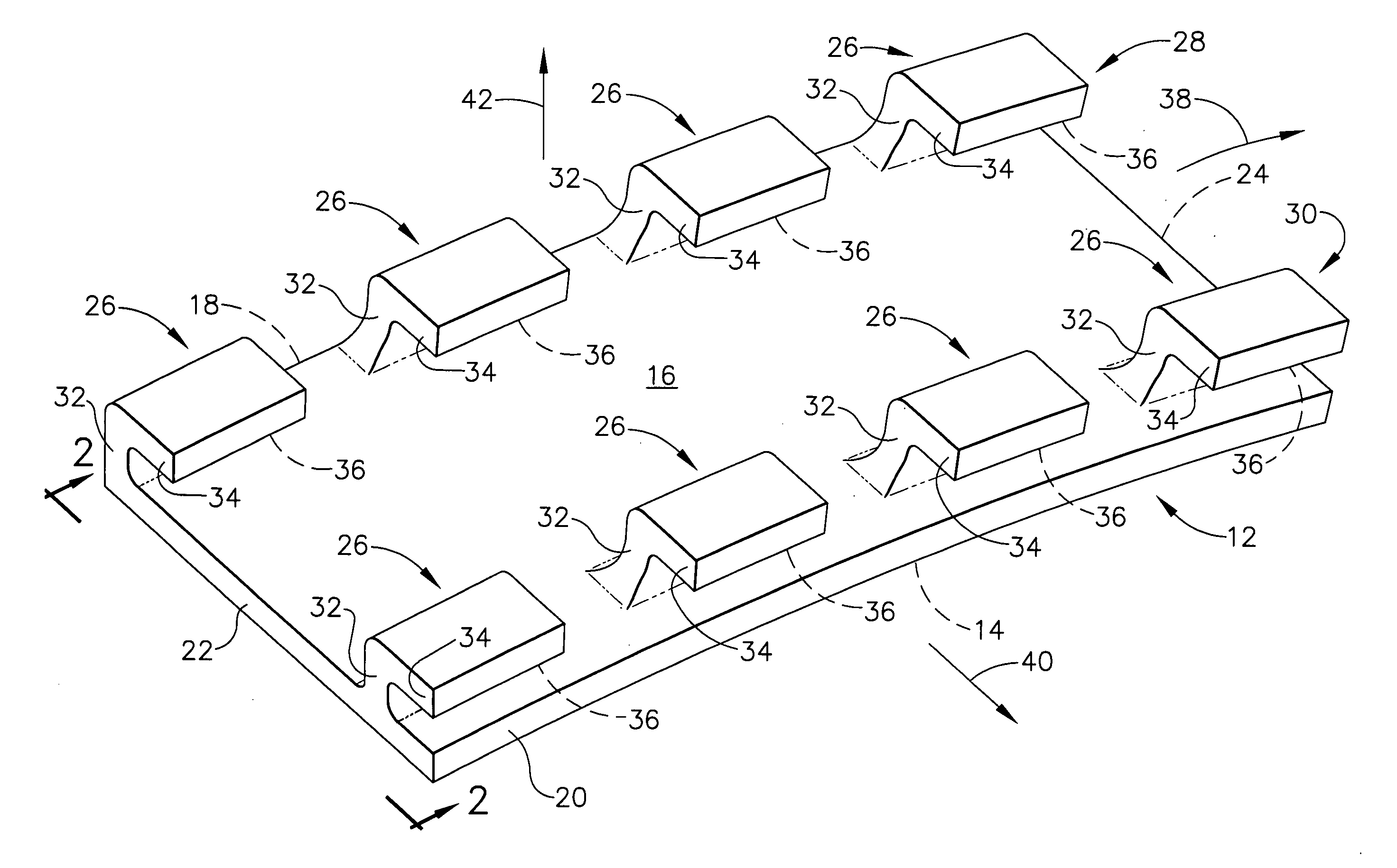

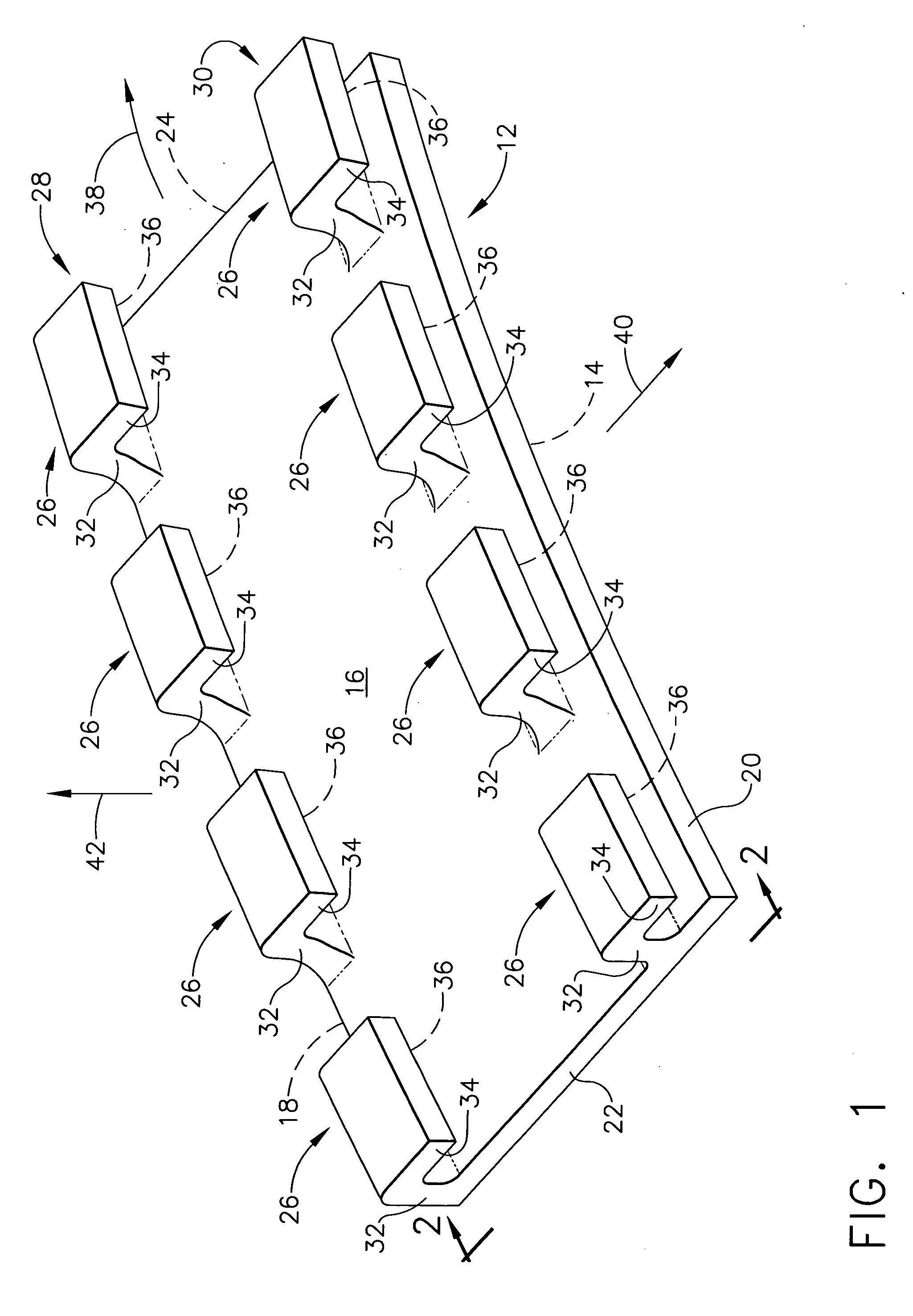

[0020]FIG. 1 is a diagrammatic perspective view of an embodiment of a turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com