Armor system

a technology of armor system and armor plate, applied in the field of armor system, can solve the problems of increasing the time and cost of armor application, inconvenient application, and the possibility of quick and easy armor application, and achieve the effect of quick and easy application and high protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

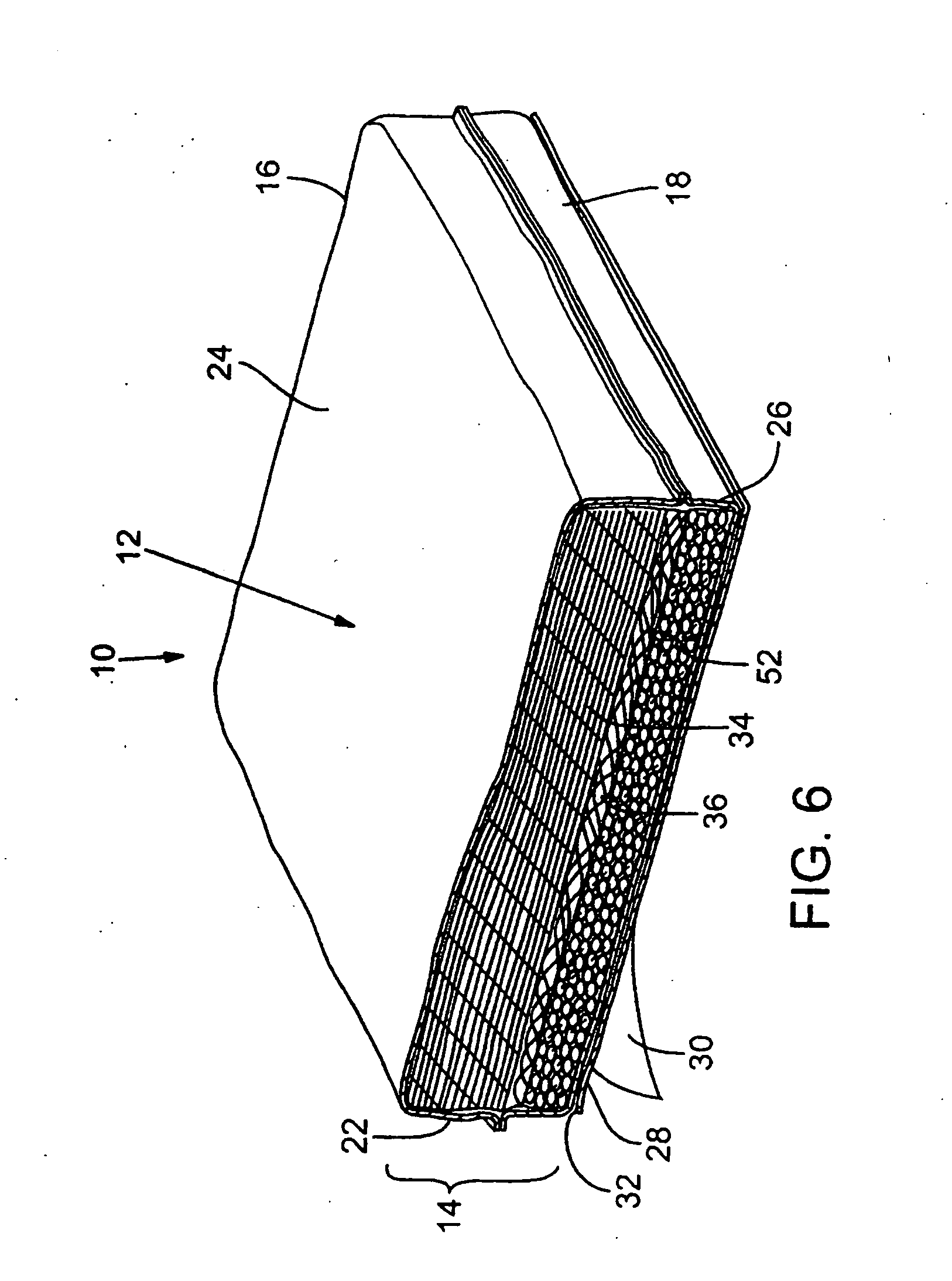

[0053] In certain embodiments, the armor system of the present invention provides an armor that can be quickly and easily applied to a body to be protected and adapted to a variety of situations depending on the level of threat and the level of protection needed. The armor system may include plural armor units that include an outer case that can be filled with a variety of protective materials either alone or in combination with other protective materials. The type and combination of materials that are enclosed within the outer case depend on several factors such as, for example, the level of threat and protection that is needed against the threat, the weight of the armor system, the need for the armor system to conform to the body to which it is to protects, and the cost of the armor system.

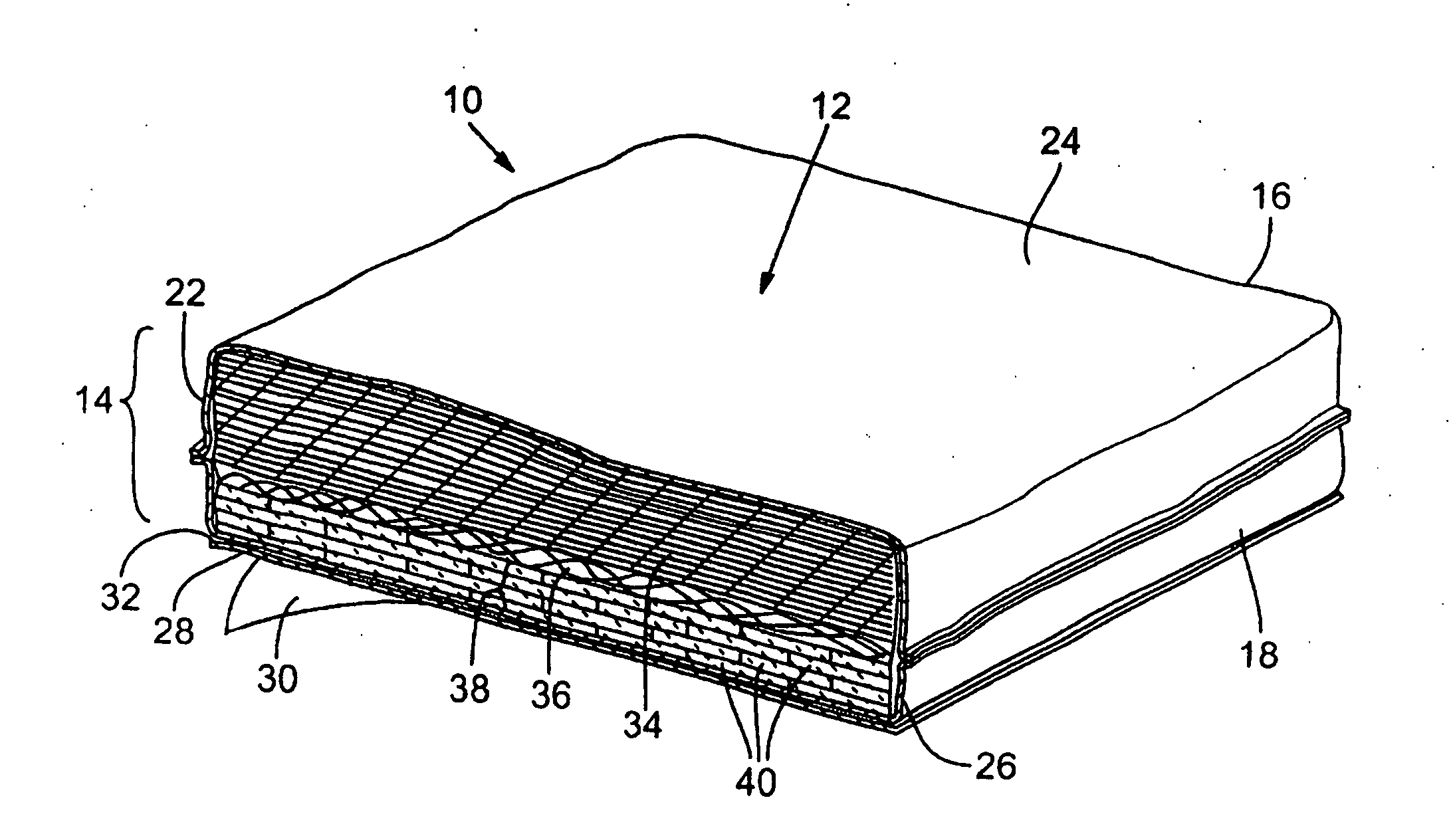

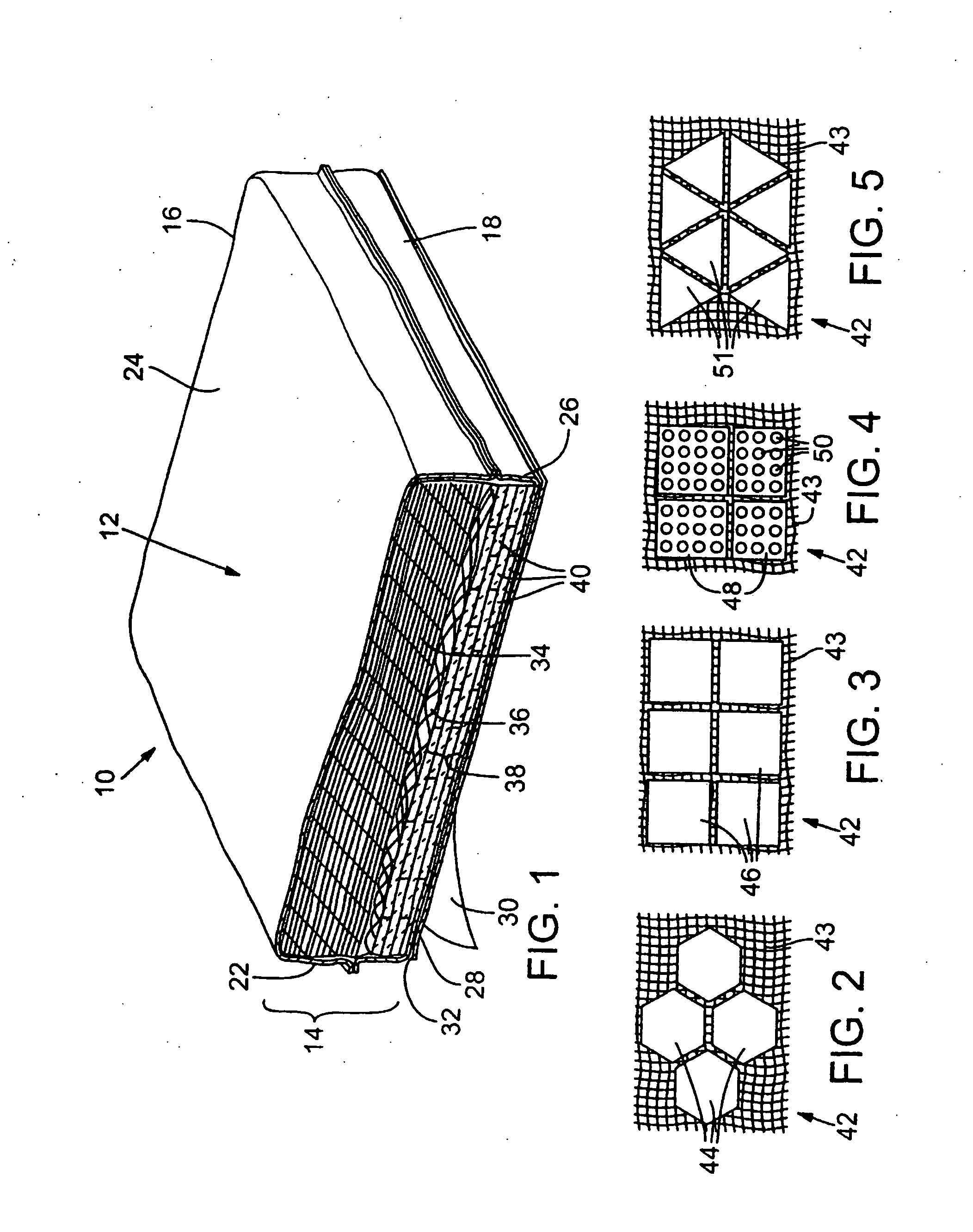

[0054]FIG. 1 shows an armor unit 10, one or more of which make up the armor system of the present invention. Although only one armor unit 10 is shown it is understood that many more armor units...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com