Airtight lid for container and method of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

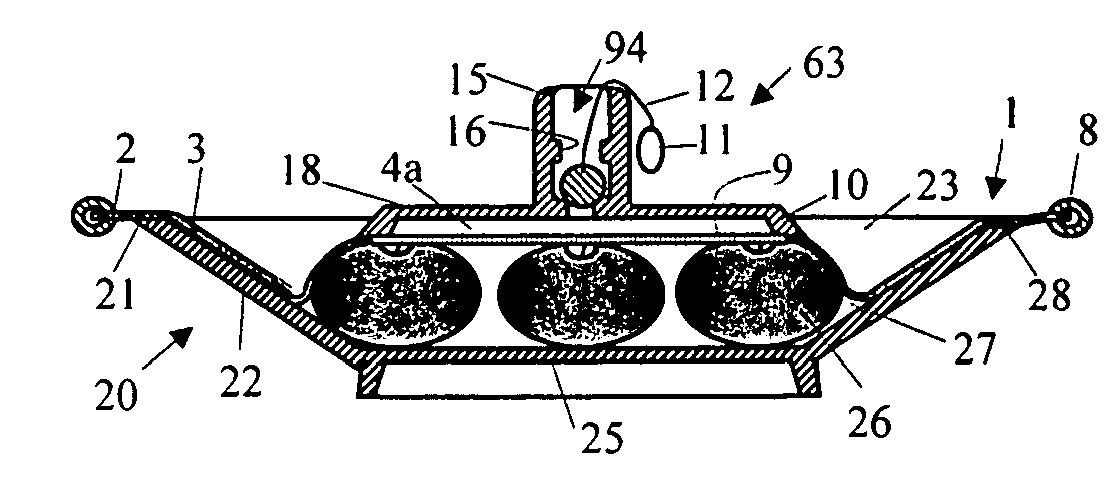

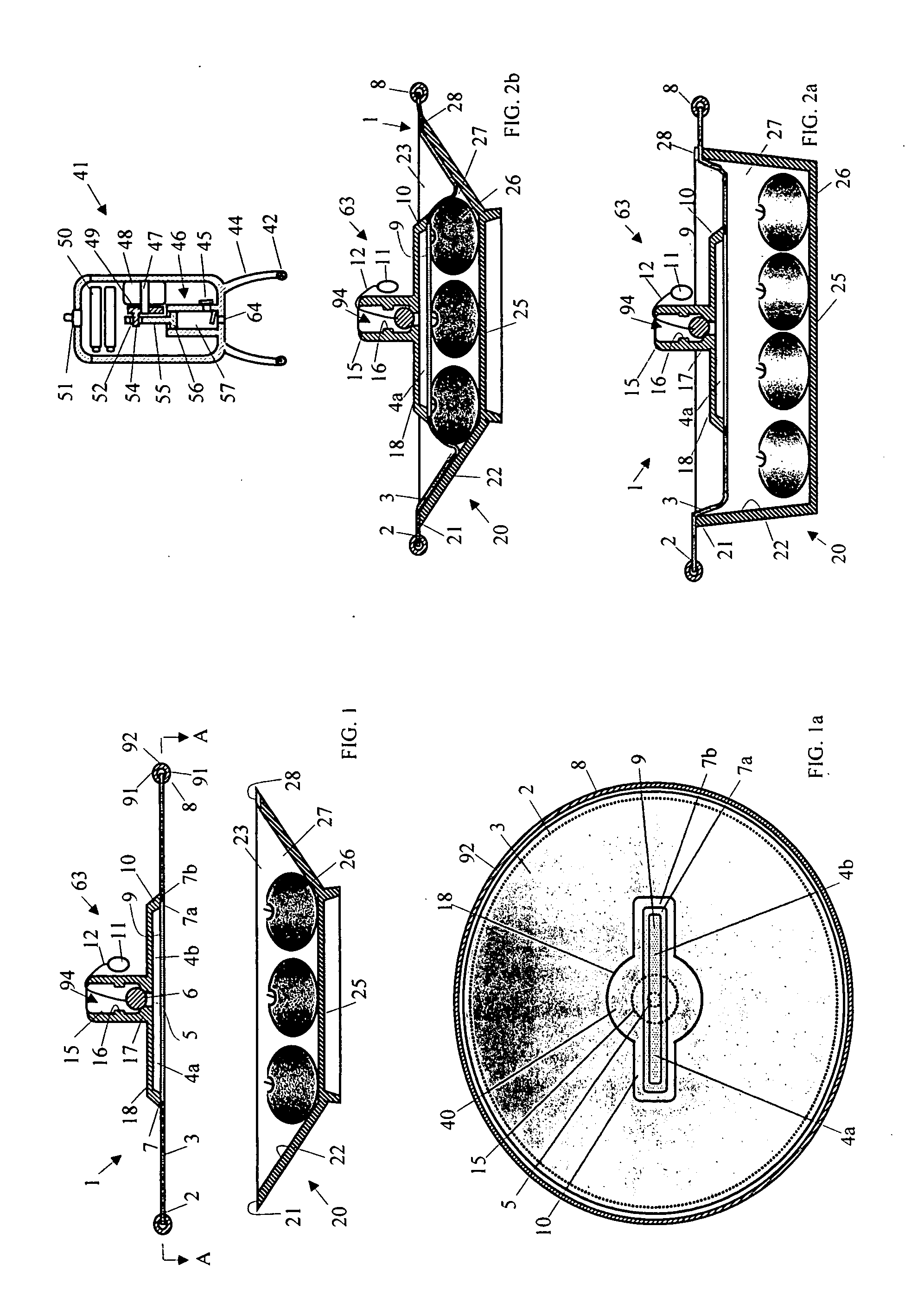

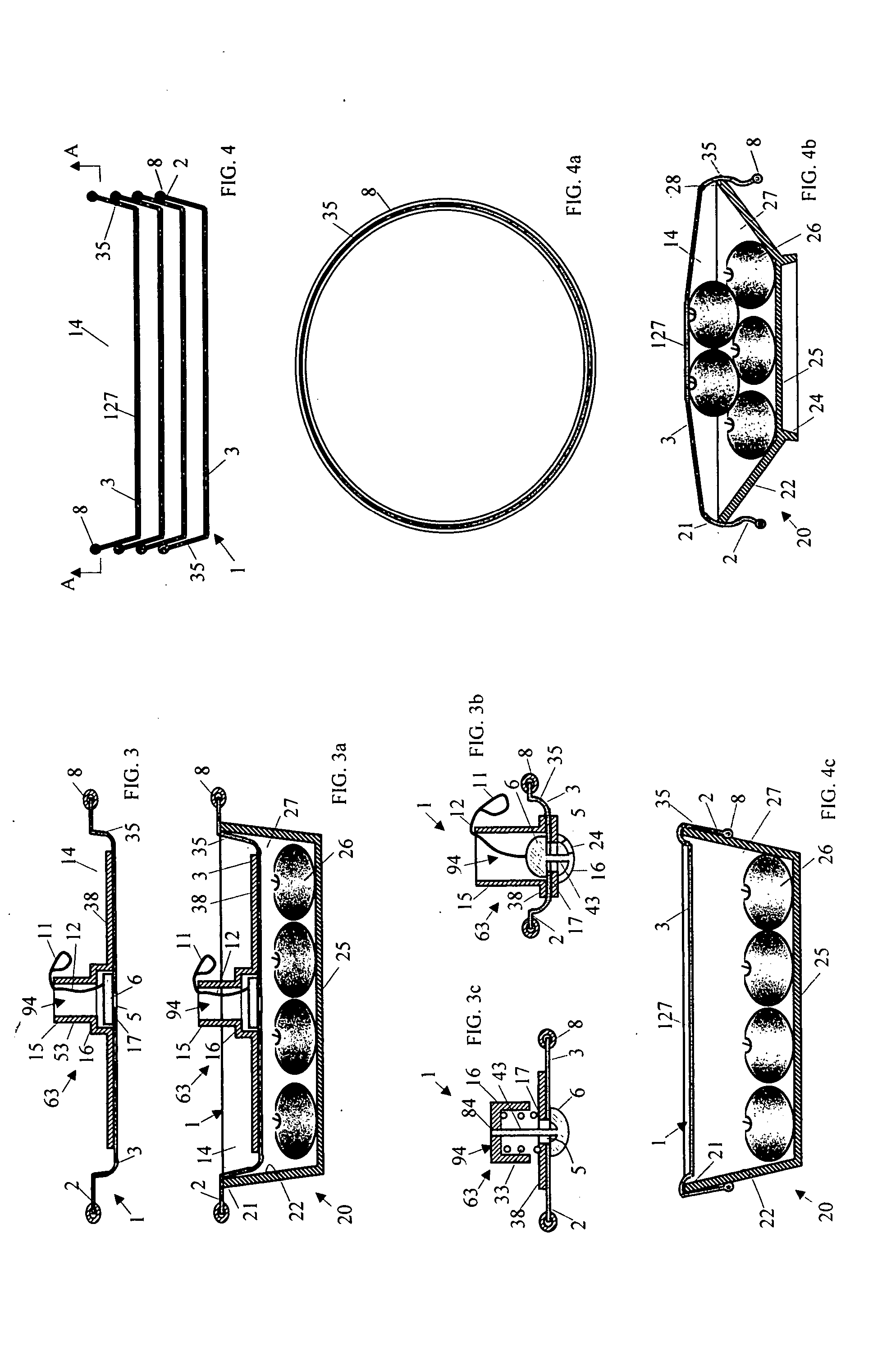

[0041]FIGS. 1 and 1a illustrate a lid 1 for a bowl or plate 20 having an open top end 23, a rim 21, a bottom 25, a side wall 22 and a chamber 27 to receive several fruits 26. Like most containers in a household, the rim 21 for bowl 20 is not perfectly flat, and may be warped or have one or more lower sections 28. Such warping or lower sections 28 would cause a gap between the currently known or available lid and the rim 21, preventing the current known lids from forming an airtight seal to the container. The lid 1 of the present invention comprises an air impermeable membrane 3 having an outer perimeter 2 larger than the rim of the container to cover the container and an enforcement ring 8 for preventing the outer perimeter of the membrane from deformation when the membrane is pulled into the container by either a subatmospheric pressure or vacuum (FIG. 2) or is pushed into the container by hand or force (FIG. 2a).

[0042] The enforcement ring 8 is made from a metal material such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com