Method and system for controlling railroad surfacing

a technology for railroads and surfacing, applied in the direction of roads, measuring devices, construction, etc., can solve the problems of poor resurfacing accuracy, built-in error in rail correction, and difficult use of existing shadowboard systems, etc., to improve resurfacing accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

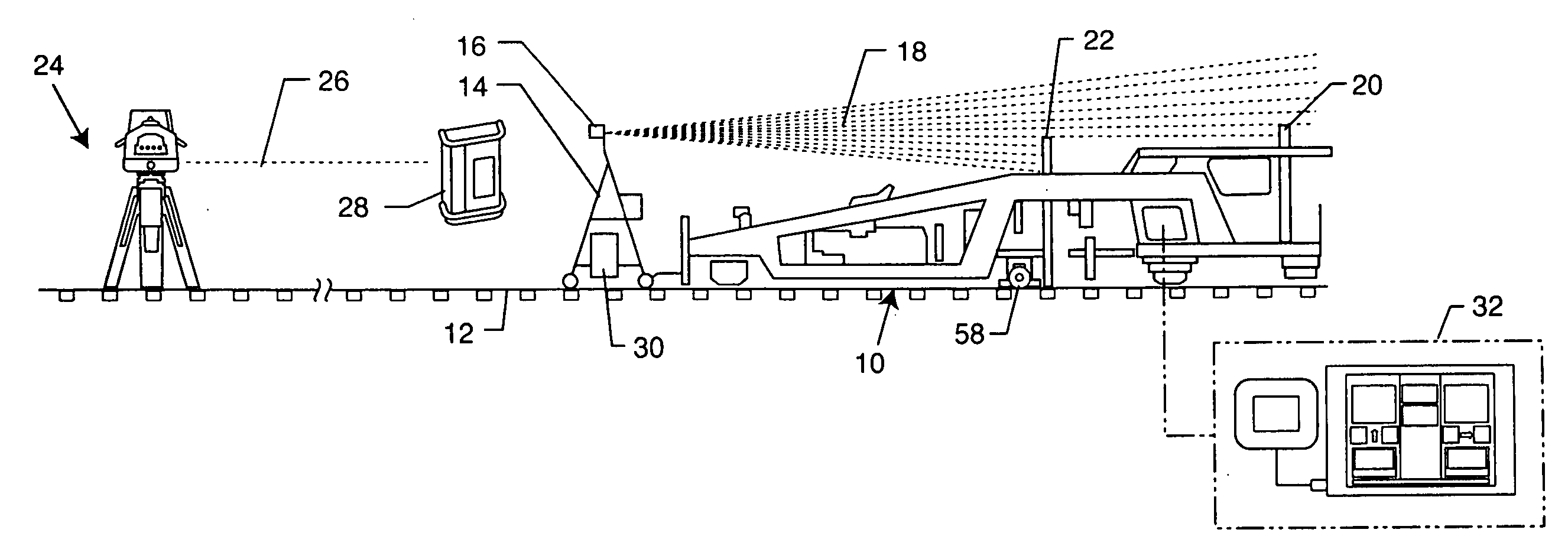

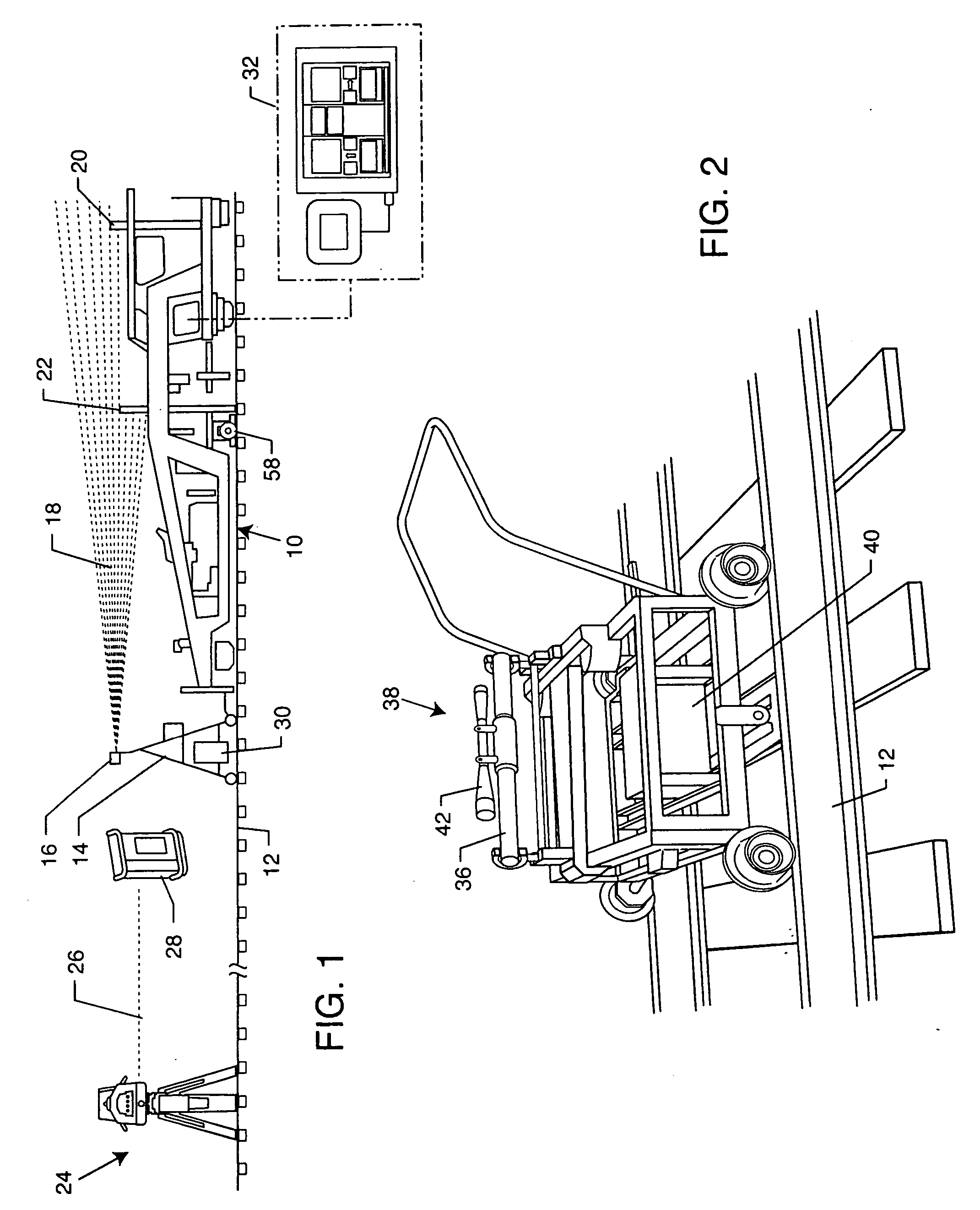

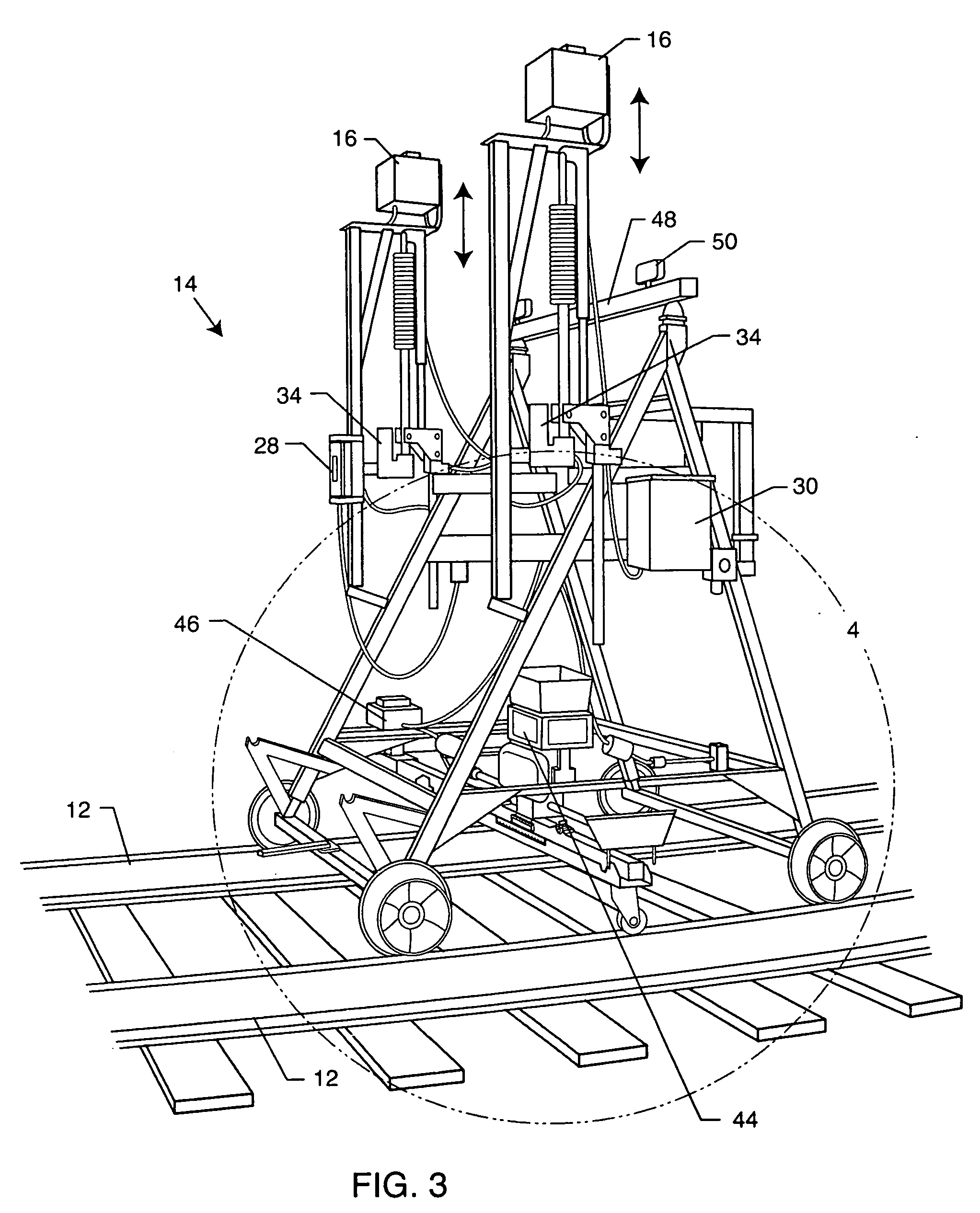

[0028] As shown in the accompanying drawings, for purpose of illustration, the present invention resides in a system and method for controlling railroad surfacing. As will be more fully discussed herein, the system and methodology of the present invention enable the automatic adjustment of the rails of the railroad track with little or no operator intervention. Proper railroad surfacing can be achieved in as little as one pass by a tamper machine by as few as a single worker. Moreover, as will be more fully discussed herein, the length of railroad track which can be adjusted and resurfaced per day is greatly increased in comparison to existing methods.

[0029] With reference now to FIG. 1, as discussed above, existing railroad surfacing systems include a tamper machine 10 which is capable of lifting and moving the rails 12 of a railroad track vertically and horizontally, and vibrating existing gravel or adding new gravel to properly raise and align the rails 12 to within accepted tol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com