Anti-bunker ammunition

a technology of ammunition and ammunition, applied in the direction of ammunition projectiles, weapons, projectiles, etc., can solve the problems of reducing the effectiveness of explosive ammunition, increasing the mass of ammunition without necessarily increasing the mass of the front part, and disorganizing or fractured explosive charge during its passag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

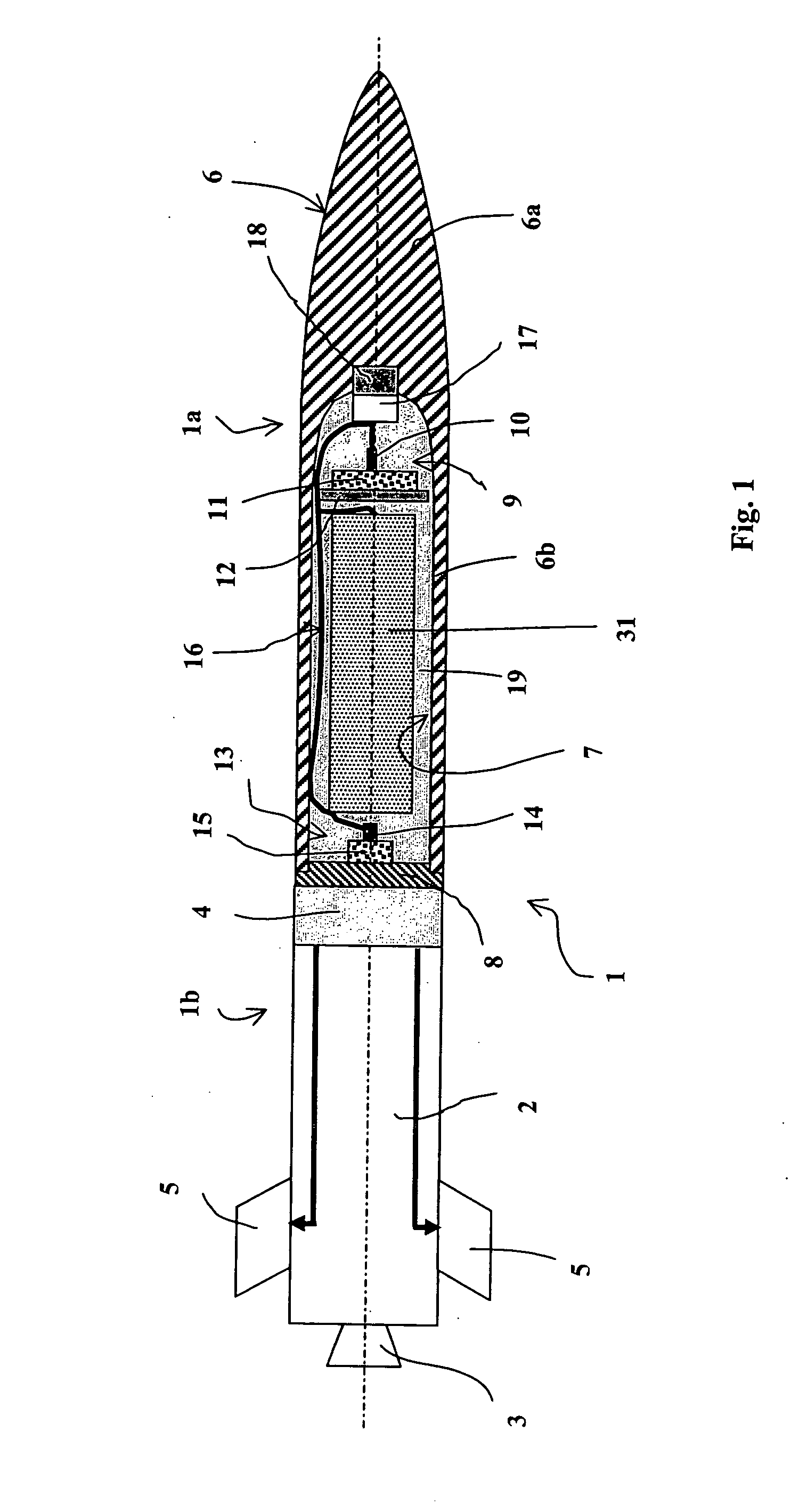

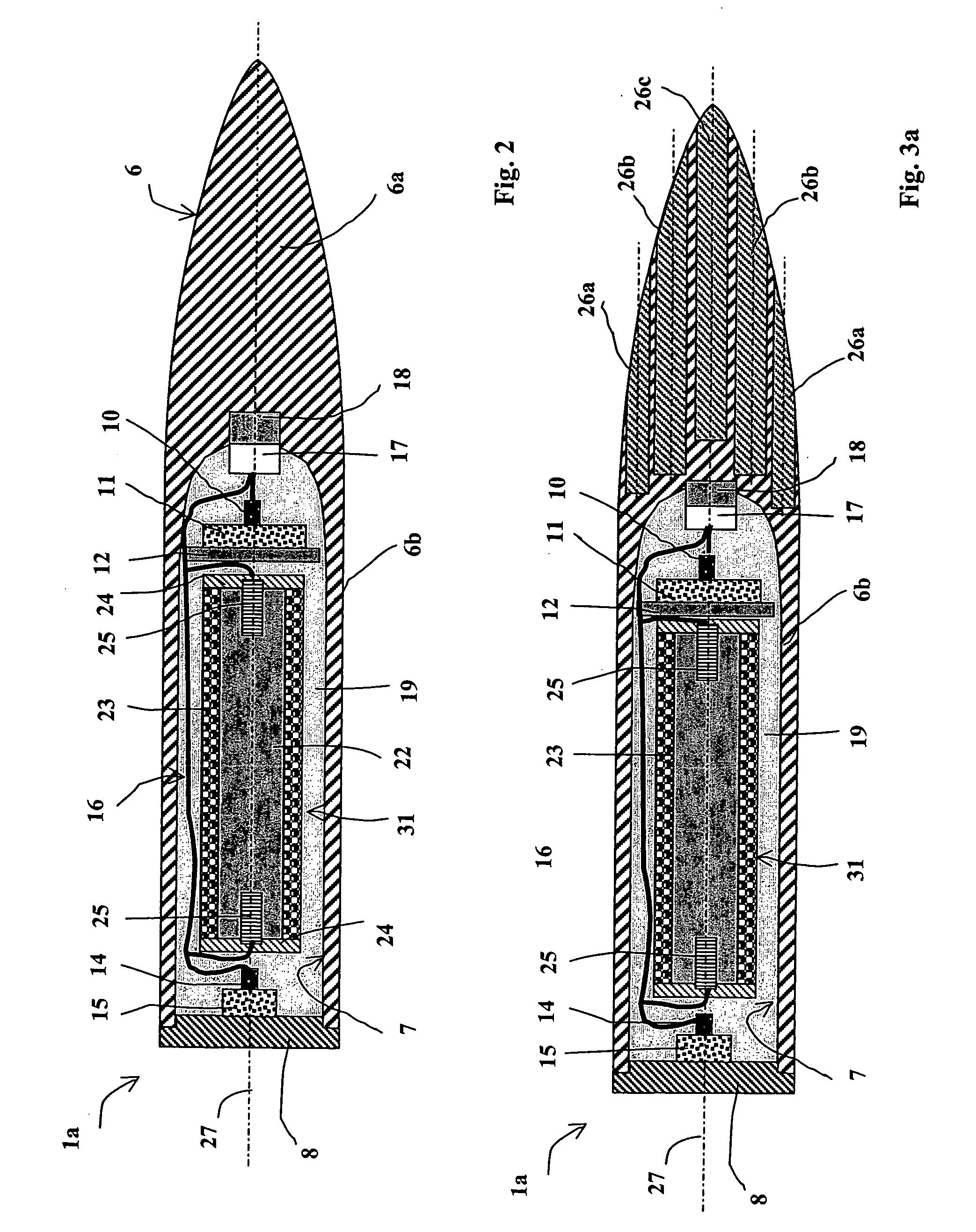

[0029] With reference to FIG. 1, an anti-bunker ammunition 1 according to one embodiment of the invention comprises a front perforating warhead 1a which here is integral with a rear part 1b comprising a propellant module 2 and an electronic guiding / piloting module 4.

[0030] The propellant module 2 is not shown here in detail. It classically encloses a gas-generating propellant charge (not shown), such gases ejected rearwards of the ammunition 1 by a nozzle 3.

[0031] The electronic guiding / piloting module 4 is also not shown in detail. It is connected to four rear piloting fins 5 formed into a cross.

[0032] The ammunition 1 thus constitutes a missile or else an air-to-ground bomb having a piloting capability to a target.

[0033] The propellant module 2 allows the projectile to be given a minimal velocity required for impact on a target, such velocity ensuring the perforation of the target. This module may thus be ignited only a few tens of meters before impact. For a concrete target o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com