Building reinforcing method, material and structure

a technology for reinforcing methods and structures, applied in the direction of building repairs, snow traps, transportation and packaging, etc., can solve the problems of reducing the internal space of the structure, and affecting the safety of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

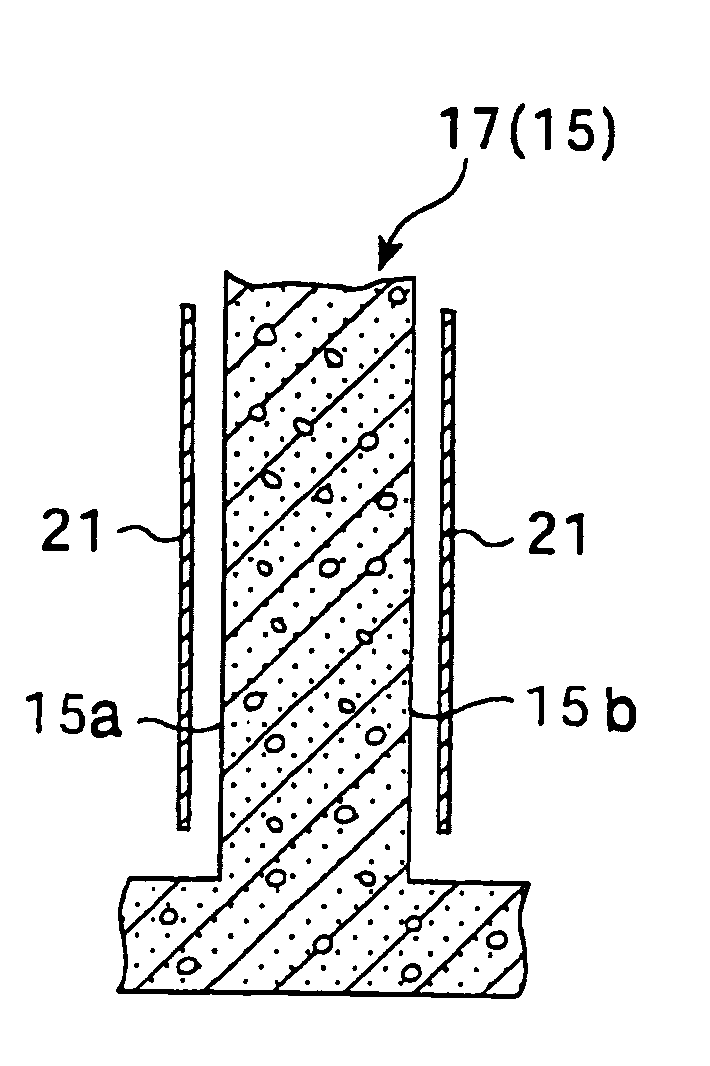

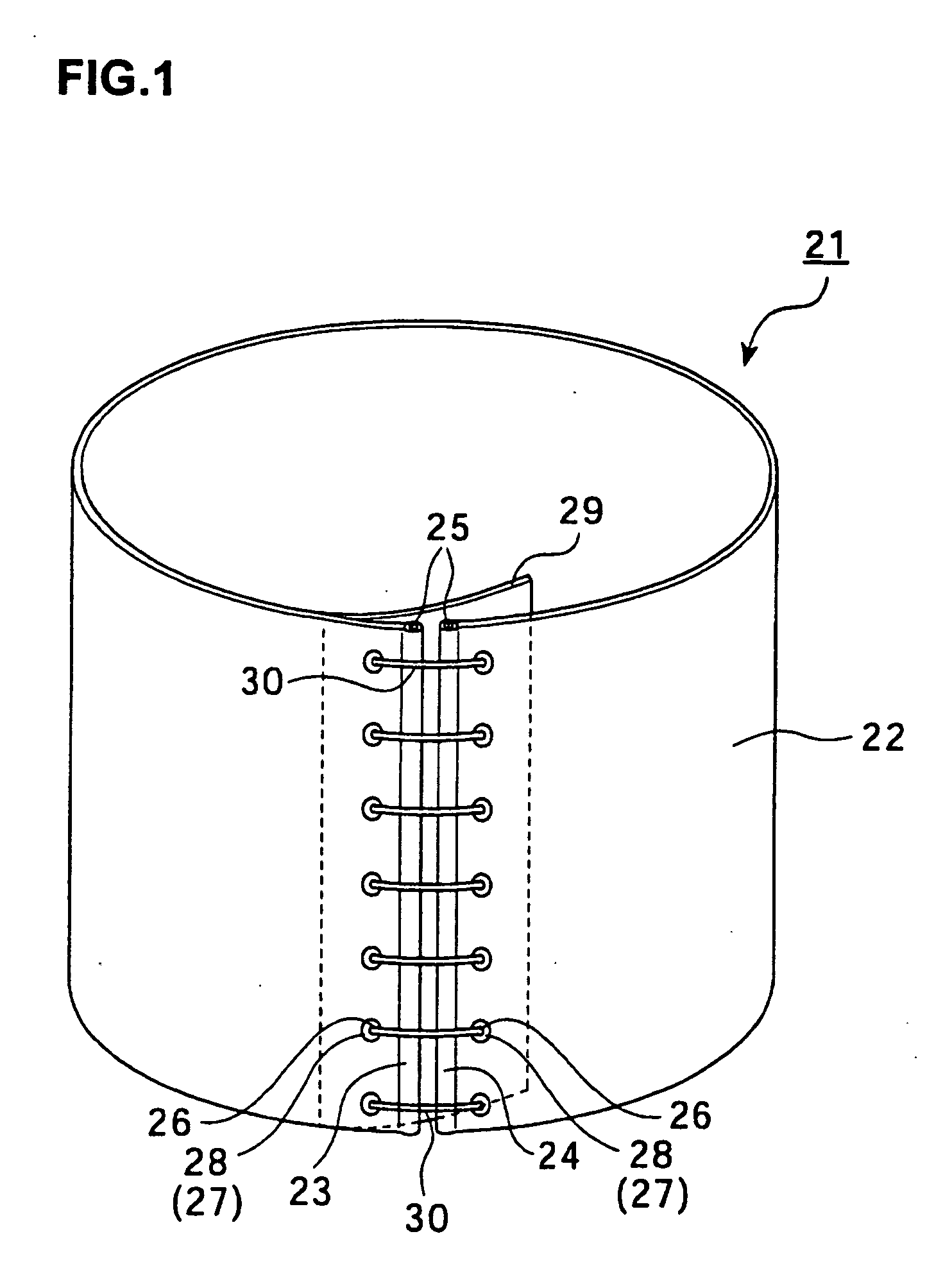

[0049]FIG. 1 is a general perspective view showing a structural example of a high-ductility material to be used in the present invention with various members, such as structural members, of a structure in order to control rupture of a member through confining volume expansion of the member accompanying rupture of the member.

[0050] As shown in FIG. 1, a high-ductility material 21 includes a sheet portion 22 having an appropriate longitudinal length and an appropriate width and serving as a main boy, one end portion 23, and the other end portion 24, the end portions 23 and 24 butting each other in the circumferential direction.

[0051] Core cords 25 are disposed respectively at one end portion 23 and the other end portion 24 of the sheet portion 22 in such a manner as to thread through the end portions 23 and 24 along the longitudinal-length direction. The core cord 25 reinforce one end portion 23 and the other end portion 24 to thereby enhance durability in the tensile direction.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com