Chemical mechanical polishing pad and chemical mechanical polishing method

a technology of mechanical polishing and chemical mechanical, applied in the direction of flexible wheel, manufacturing tools, lapping machines, etc., can solve the problems of unsatisfactory polishing surface state, greatly affected polishing result, and poor polishing rate, and achieve excellent polishing rate and suppress the occurrence of scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(1) Manufacture of Chemical Mechanical Polishing Pad

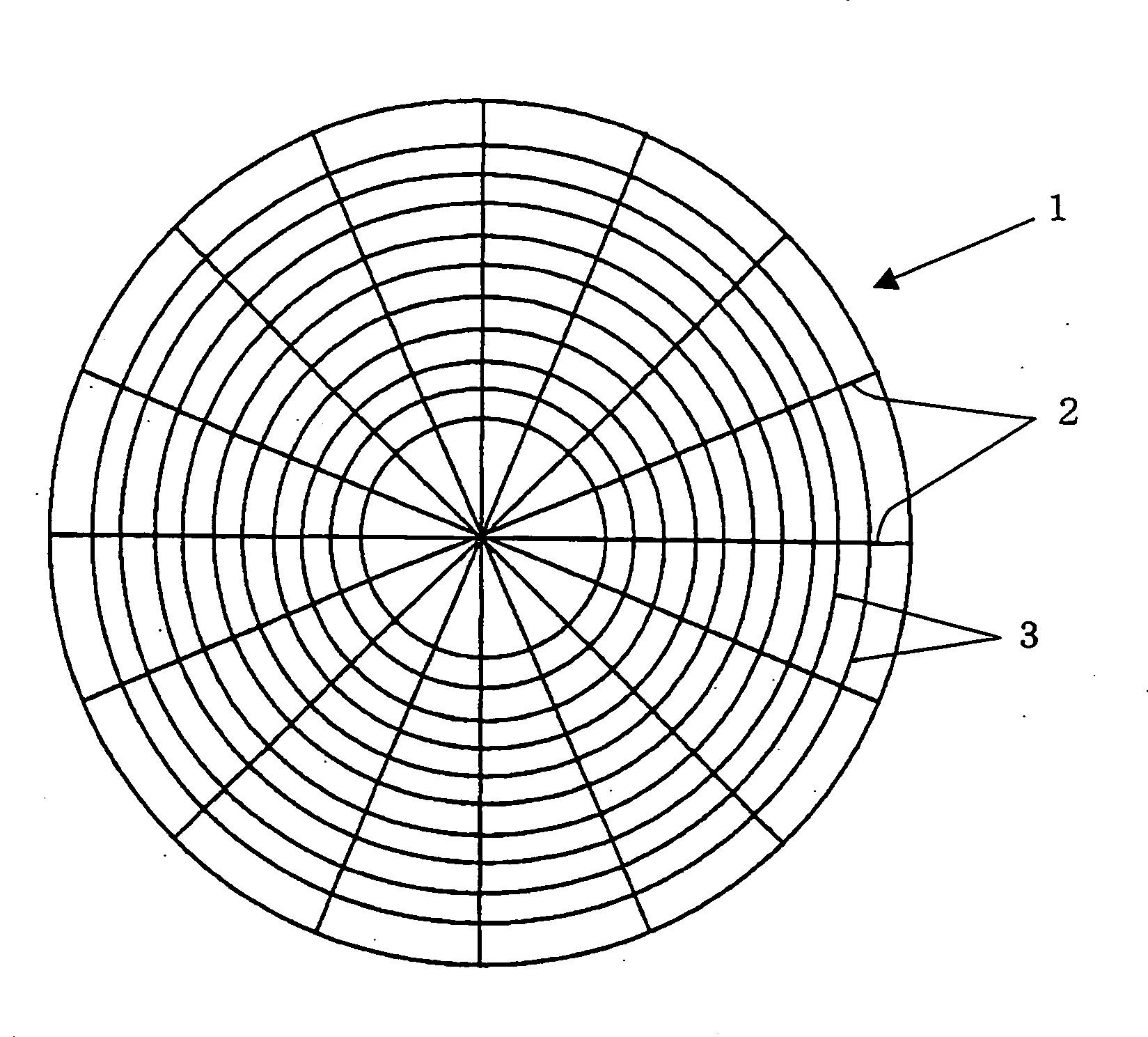

[0097] 80 parts by volume (equivalent to 72 parts by mass) of 1,2-polybutadiene (manufactured by JSR Corporation, trade name of JSR RB830) which would be crosslinked to become a water-insoluble matrix and 20 parts by volume (equivalent to 28 parts by mass) of β-cyclodextrin (manufactured by Bio Research Corporation of Yokohama, trade name of Dexy Pearl β-100, average particle diameter of 20 μm) as water-soluble particles were kneaded together by an extruder set at 160° C. Thereafter, 1.0 part by volume (equivalent to 1.1 parts by mass) of dicumyl peroxide (manufactured by NOF Corporation, trade name of Percumyl D) was added to and kneaded with the above kneaded product at 120° C. to obtain a pellet. The resulting kneaded product was then heated in a metal mold at 170° C. for 18 minutes to be crosslinked so as to obtain a disk-like molded product having a diameter of 600 mm and a thickness of 2.5 mm. Concentrically circular groove...

example 2

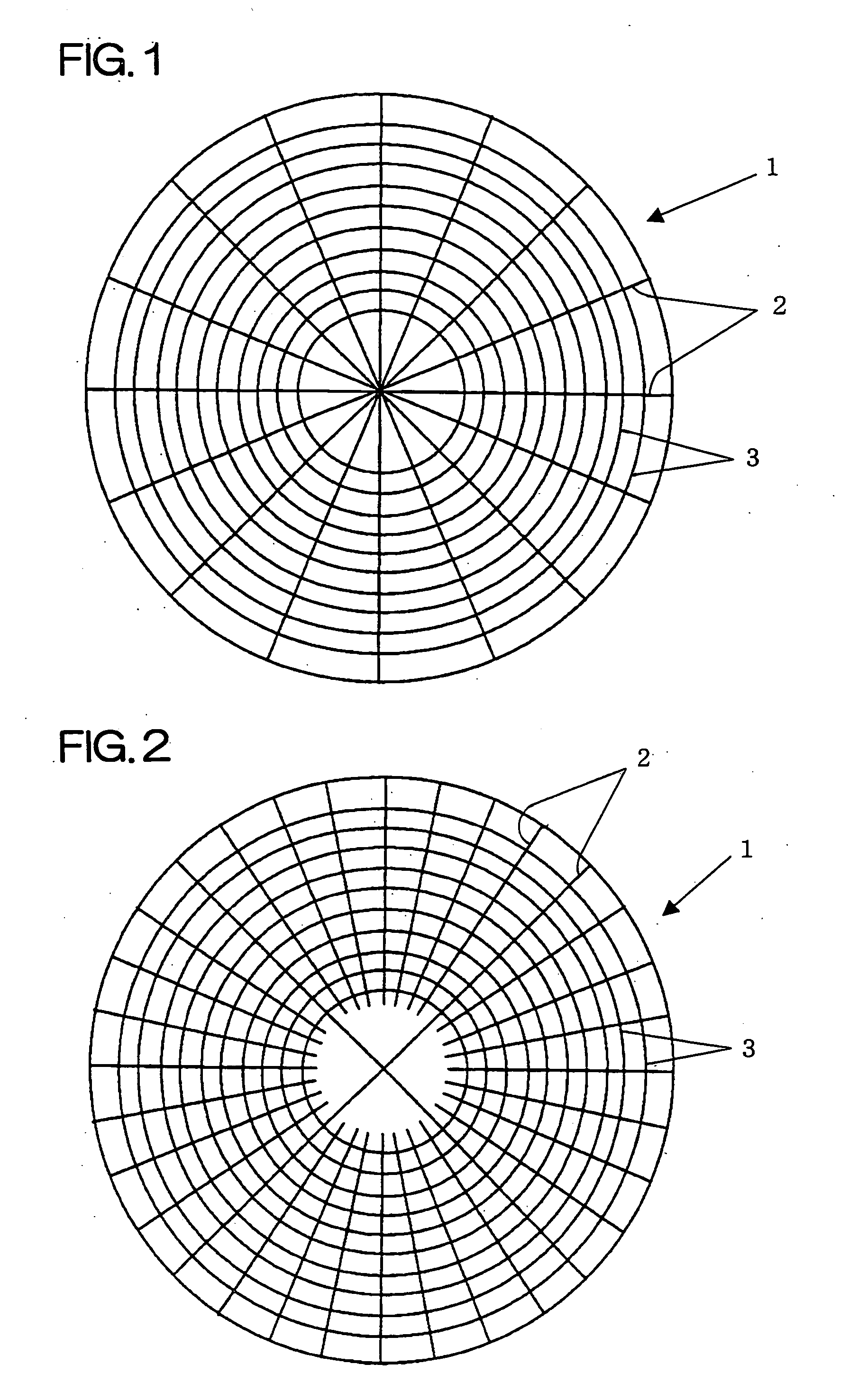

[0105] A chemical mechanical polishing pad was manufactured in the same manner as in Example 1 except that 4 linear grooves (having a width of 1.0 mm and a depth of 1.0 mm) were formed from the center to the peripheral end of the pad as a second group of grooves in such a manner that they were in contact with one another at the center of the polishing surface of the pad and the angle between adjacent linear grooves was 90° and that 28 linear grooves were formed from a portion 25 mm away from the center of the pad to the peripheral end in such a manner that the angle between adjacent linear grooves was 11.25°. The arrangement of the formed grooves is shown in the diagram of FIG. 2. The surface roughness of the inner wall of each of the formed grooves was 3.9 μm.

[0106] The polishing rate and the number of scratches were evaluated in the same manner as in Example 1 except that the above polishing pad was used. As a result, the polishing rate was 220 nm / min and no scratch was observed....

example 3

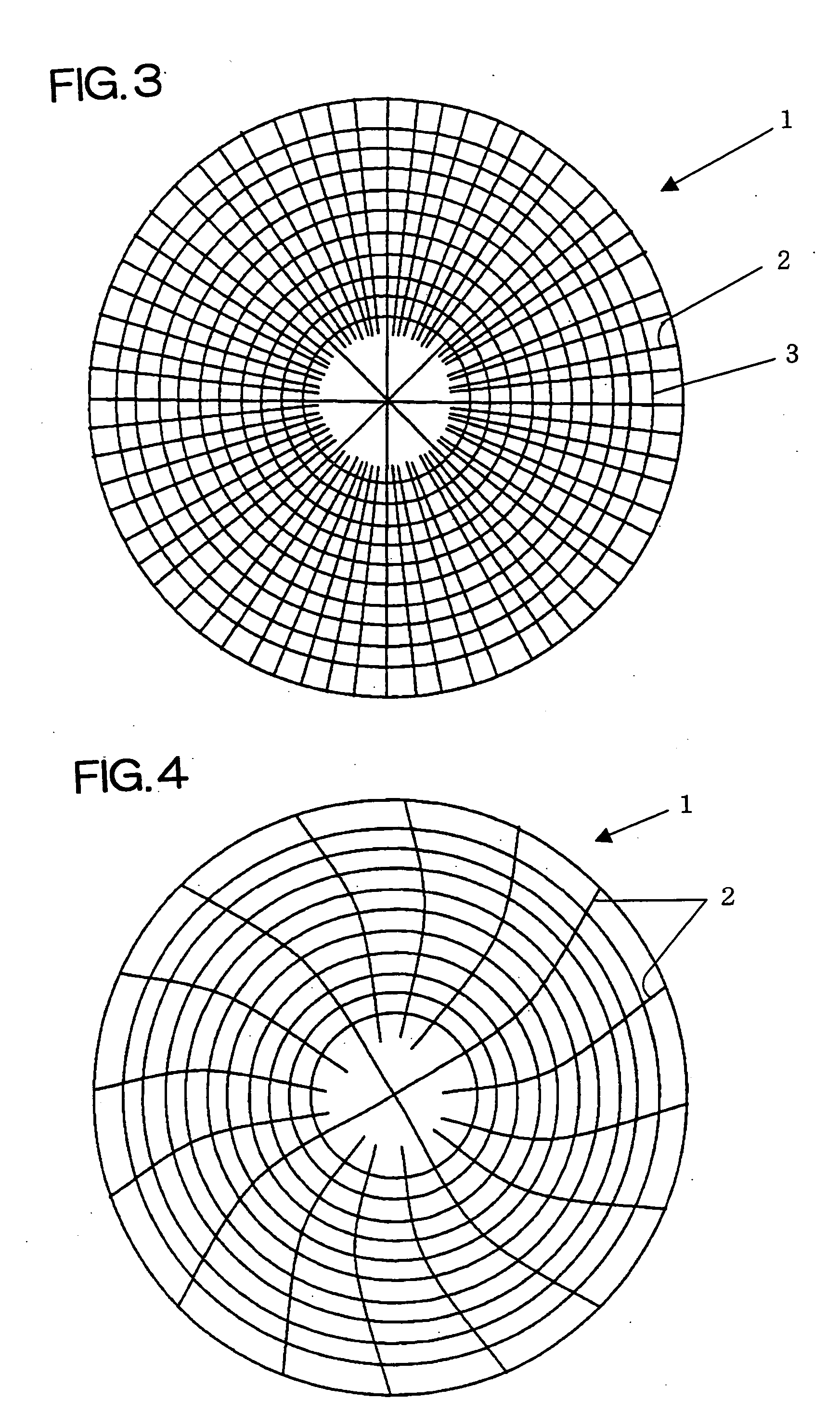

[0107] 64 parts by volume (equivalent to 58 parts by mass) of 1,2-polybutadiene (manufactured by JSR Corporation, trade name of JSR RB830), 16 parts by volume (equivalent to 14 parts by mass) of a block copolymer of 1,2-polybutadiene and polystyrene (manufactured by JSR Corporation, trade name of TR2827) and 20 parts by volume (equivalent to 28 parts by mass) of β-cyclodextrin (manufactured by of Bio Research Corporation of Yokohama, trade name of Dexy Pearl β-100, average particle diameter of 20 μm) as water-soluble particles were kneaded together by an extruder set at 160° C. Thereafter, 0.5 part by volume (equivalent to 0.56 part by mass) of dicumyl peroxide (manufactured by NOF Corporation, trade name of Percumyl D) was added to and kneaded with the above kneaded product at 120° C. to obtain a pellet. The resulting kneaded product was then heated in a metal mold at 180° C. for 10 minutes to be crosslinked so as to obtain a disk-like molded product having a diameter of 600 mm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com