Trim for hose faucet

a hose faucet and hose technology, applied in valve housings, service pipe systems, mechanical devices, etc., can solve the problems of reducing reducing air infiltration, so as to reduce the likelihood of any pipes freezing, reduce air infiltration, and reduce the effect of air infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

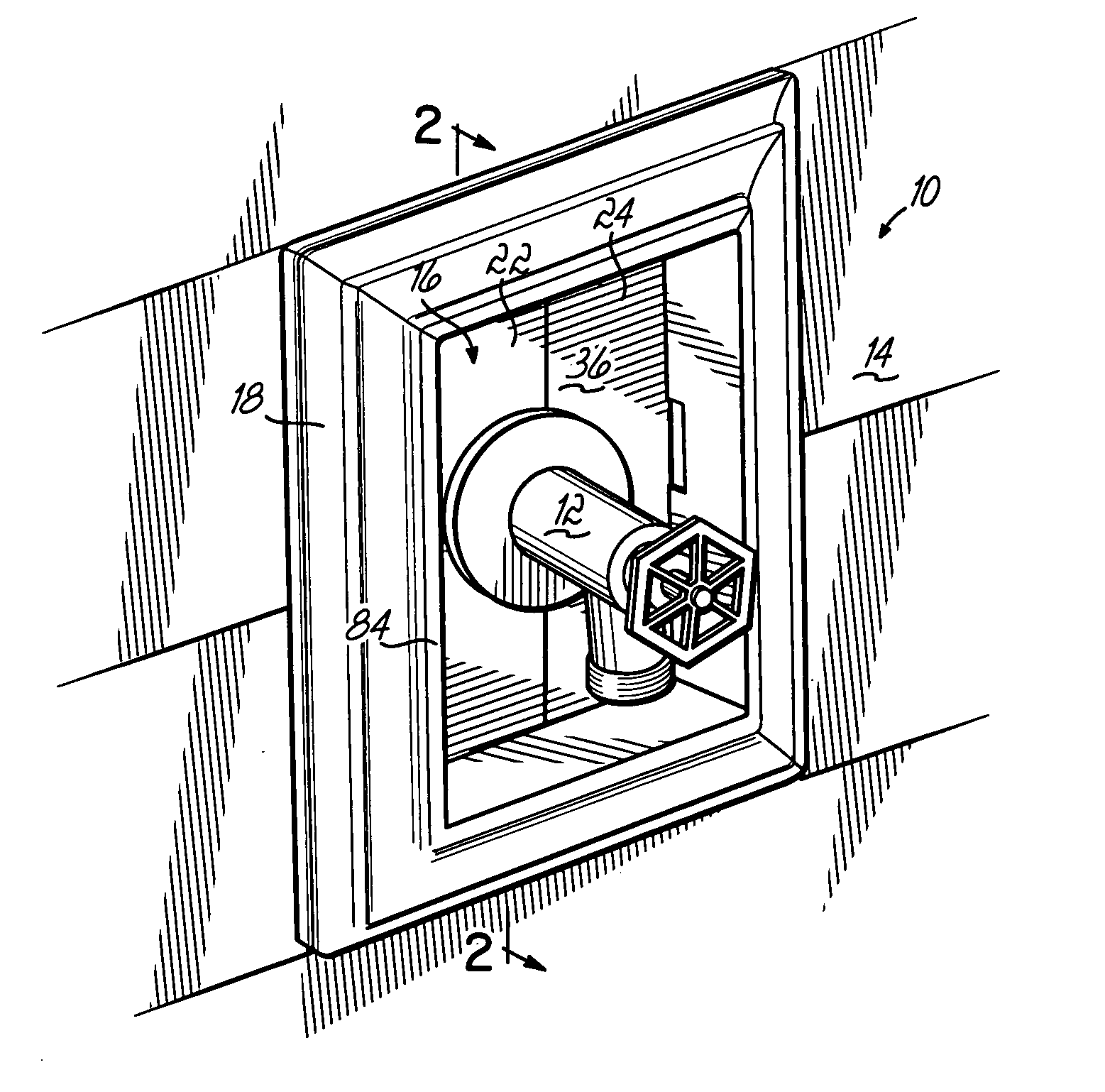

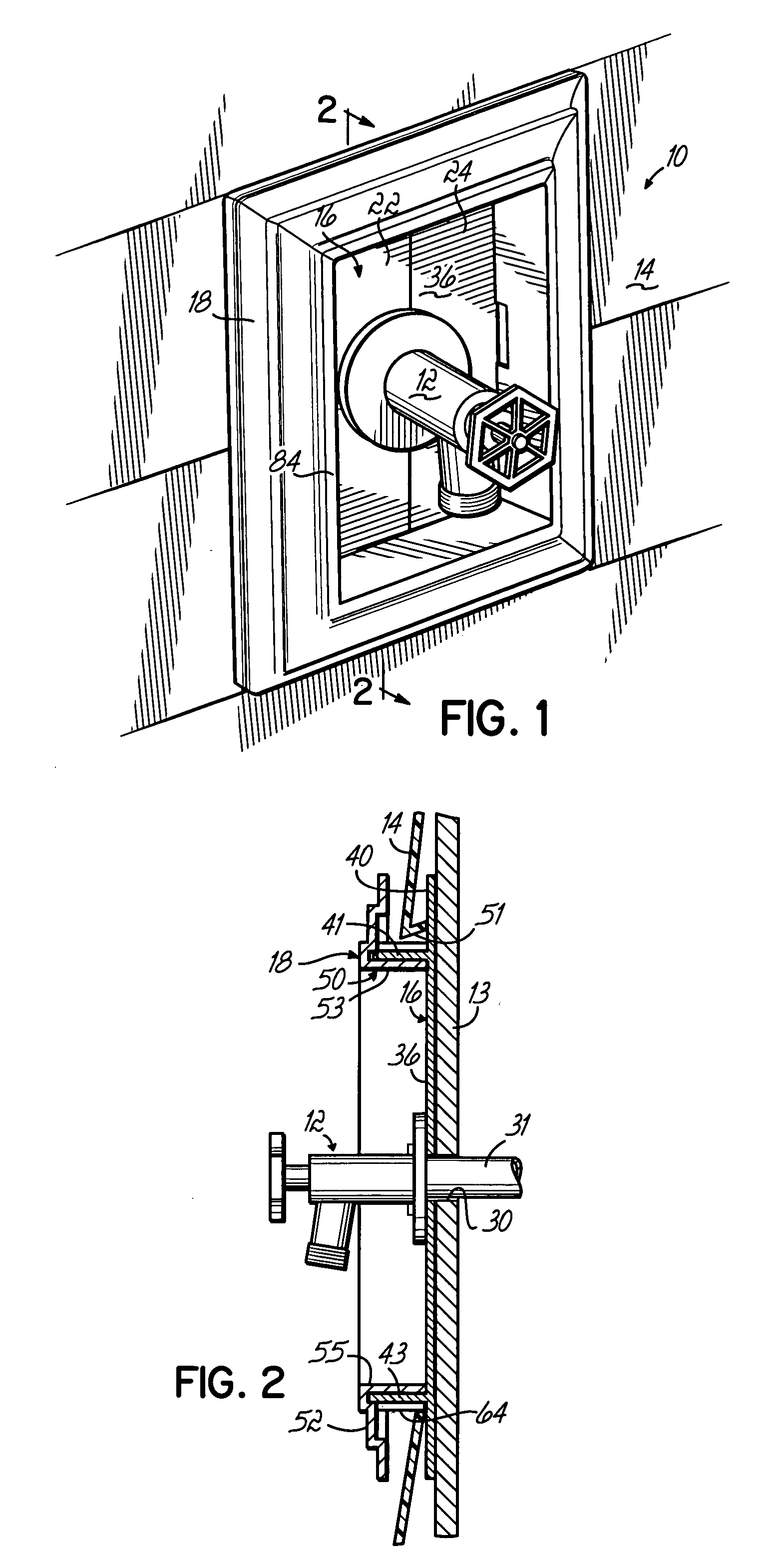

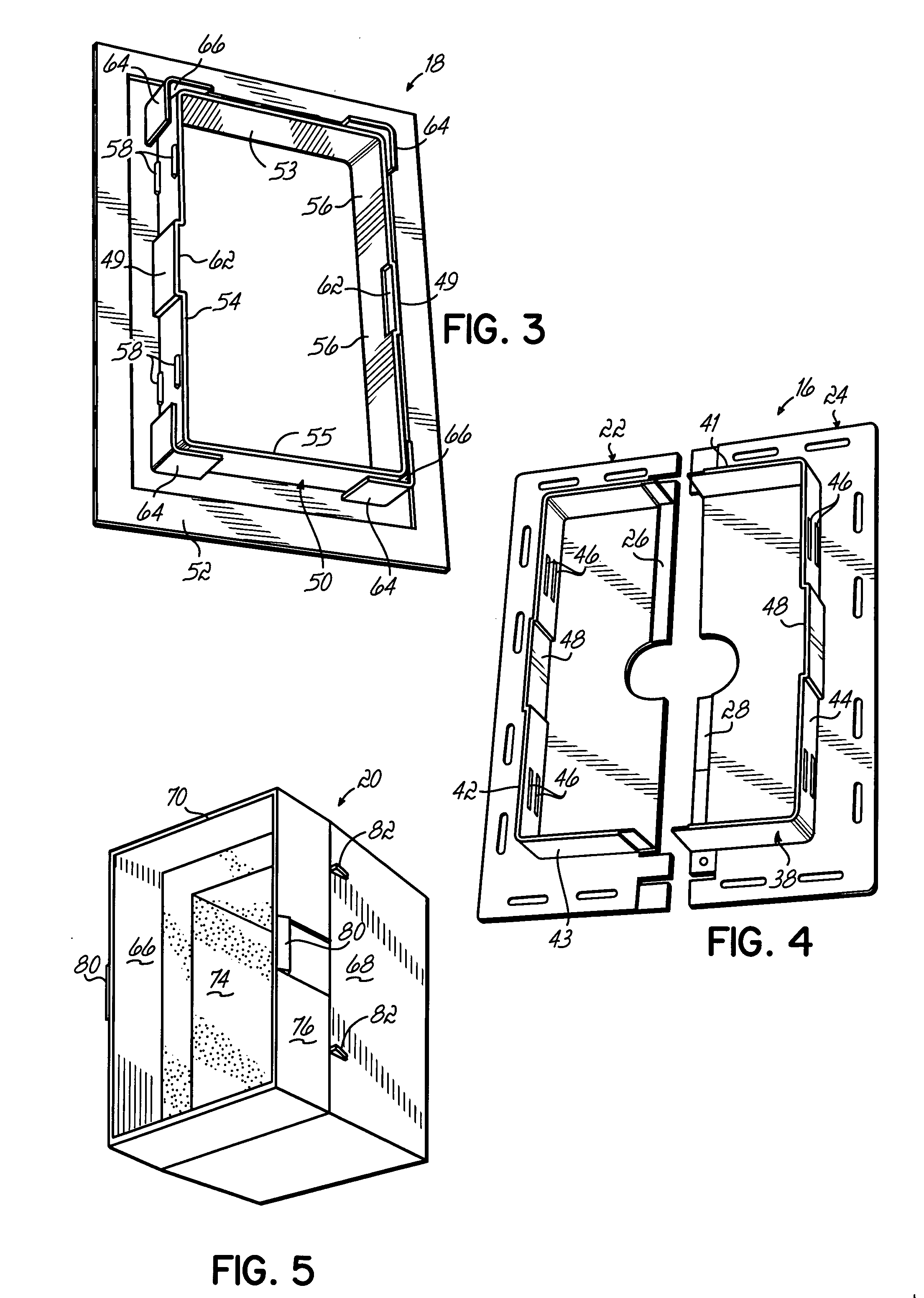

[0012] As shown in FIG. 1, the present invention is a trim unit 10 used to surround a faucet 12 on a building wall 13 which is covered with siding 14. The trim unit includes a base 16, a trim ring 18 and an insulating cover 20. The base unit 16 as shown includes two mirror image sections 22 and 24. These have mirror image mating edges 26 and 28 which, when assembled, define a hole 30 which is designed to provide for passage of a pipe 31. The two bases 22 and 24 are assembled to form the combined base 16 which then has a back wall 36 which defines hole 30 and a wall 38. Extending from the base of wall 38 is a peripheral nail flange 40 which extends around the entire base unit 16.

[0013] Wall 38 includes upper and lower sections 41and 43 and two side sections 42 and 44. The side sections 42 and 44 include slots 46 which are adapted to allow the trim ring 18 to snap onto the base 16, as explained hereinafter. The side sections 42 and 44 further include notched portions 48 which are aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com