Method and apparatus for moderating the temperature of an internal combustion engine of a motor vehicle

a technology for internal combustion engines and motor vehicles, which is applied in the direction of signal processing for cooling apparatuses, liquid cooling, coolant flow control, etc., can solve the problems of inability to achieve the effect of preheating an internal combustion engine, and the properties of the internal combustion engine are relatively poor, and the methods proposed in the past for this purpose, particularly latent heat exchangers or heat insulated reservoirs built into the cooling system, have not been considered practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

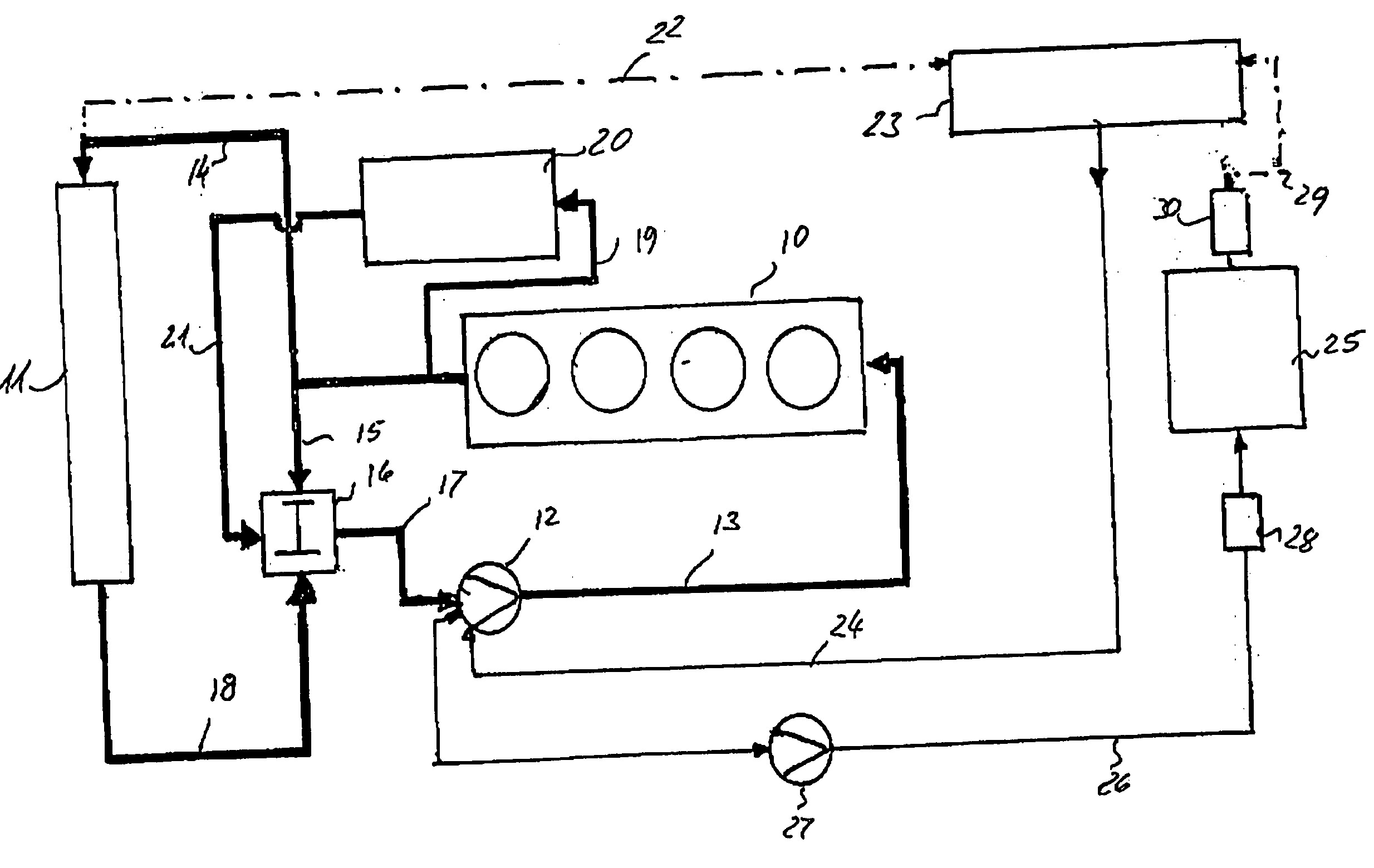

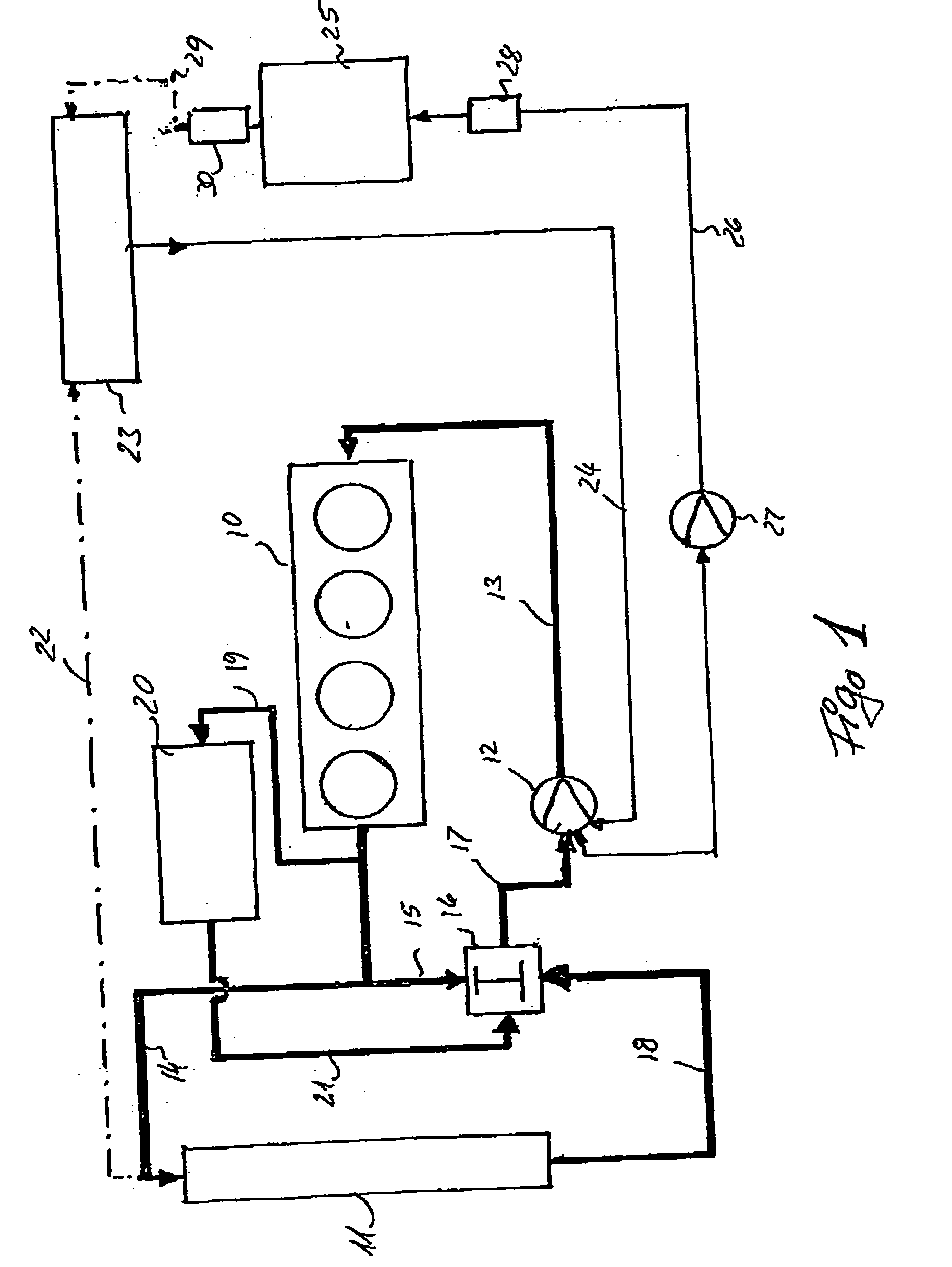

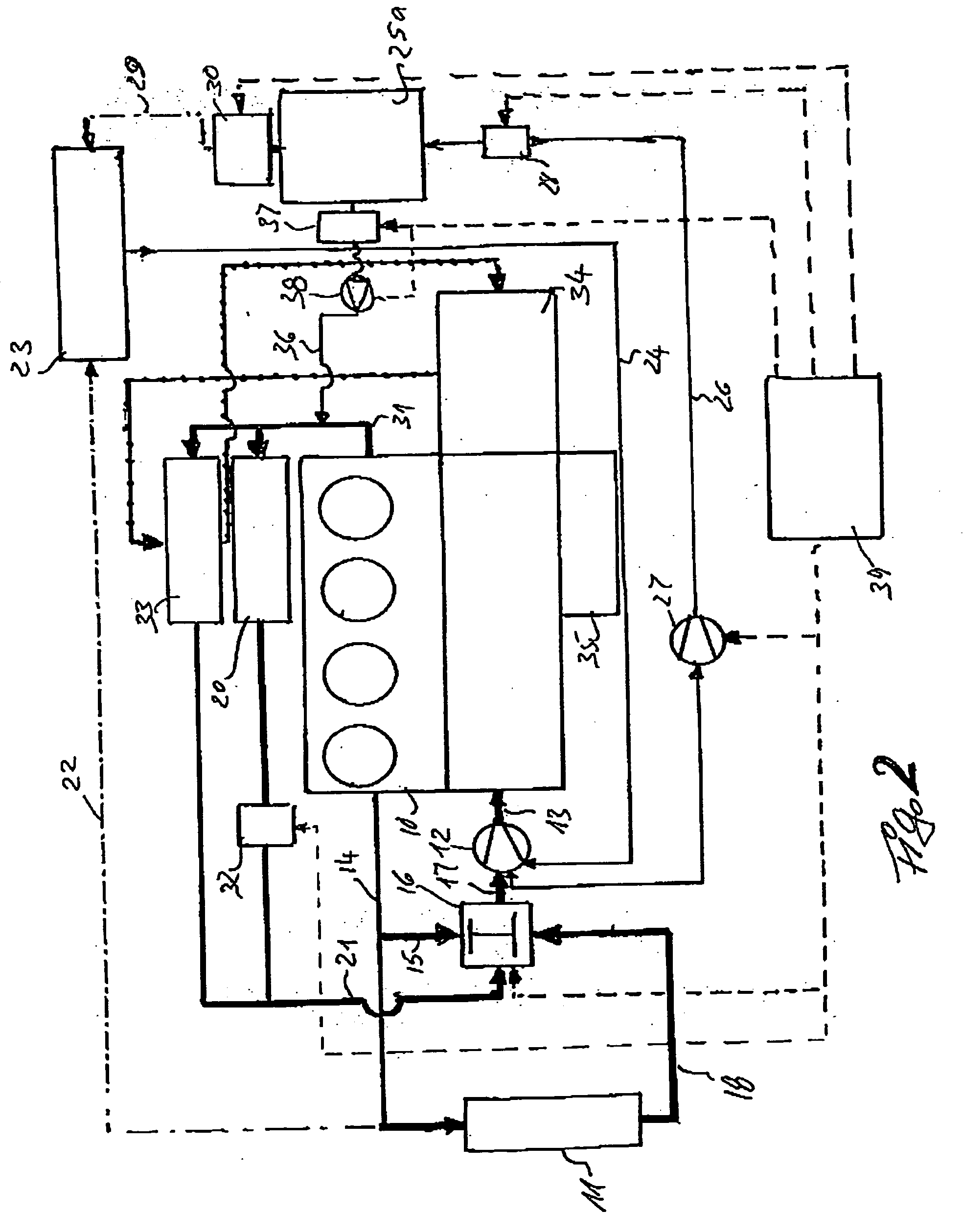

[0022] The internal combustion engine 10 shown in FIG. 1 is located with a radiator 11 in a cooling system. A pump 12 pumps coolant to the engine 10 via a cooling system conduit 13. The coolant leaving the engine 10 flows to the inlet to the radiator 11 via a conduit 14. A bypass conduit 15 branches off from the conduit 14 and leads to a thermostat valve 16, through which the coolant, arriving from the engine 10, can be aspirated directly by the coolant pump 12 via a conduit 17. When the coolant is cold, the thermostat valve 16 keeps the communication open between the bypass conduit 15 and the conduit 17 that leads to the coolant pump 12, so that the coolant leaving the engine is returned directly to the engine 10 without passing through the radiator 11.

[0023] A conduit 18, which coming from the radiator 11 is connected to the thermostat valve 16. As soon as the coolant flowing in via the bypass conduit 15 has reached a predetermined temperature, the thermostat valve 16 begins to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com