Multi-layer absorbent wound dressing

a wound dressing and absorbent technology, applied in the field of multi-layer absorbent wound dressings, can solve the problems of affecting healing, affecting healing, and requiring frequent replacement, and achieve the effects of reducing pain, reducing pain, and reducing the amount of wound fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

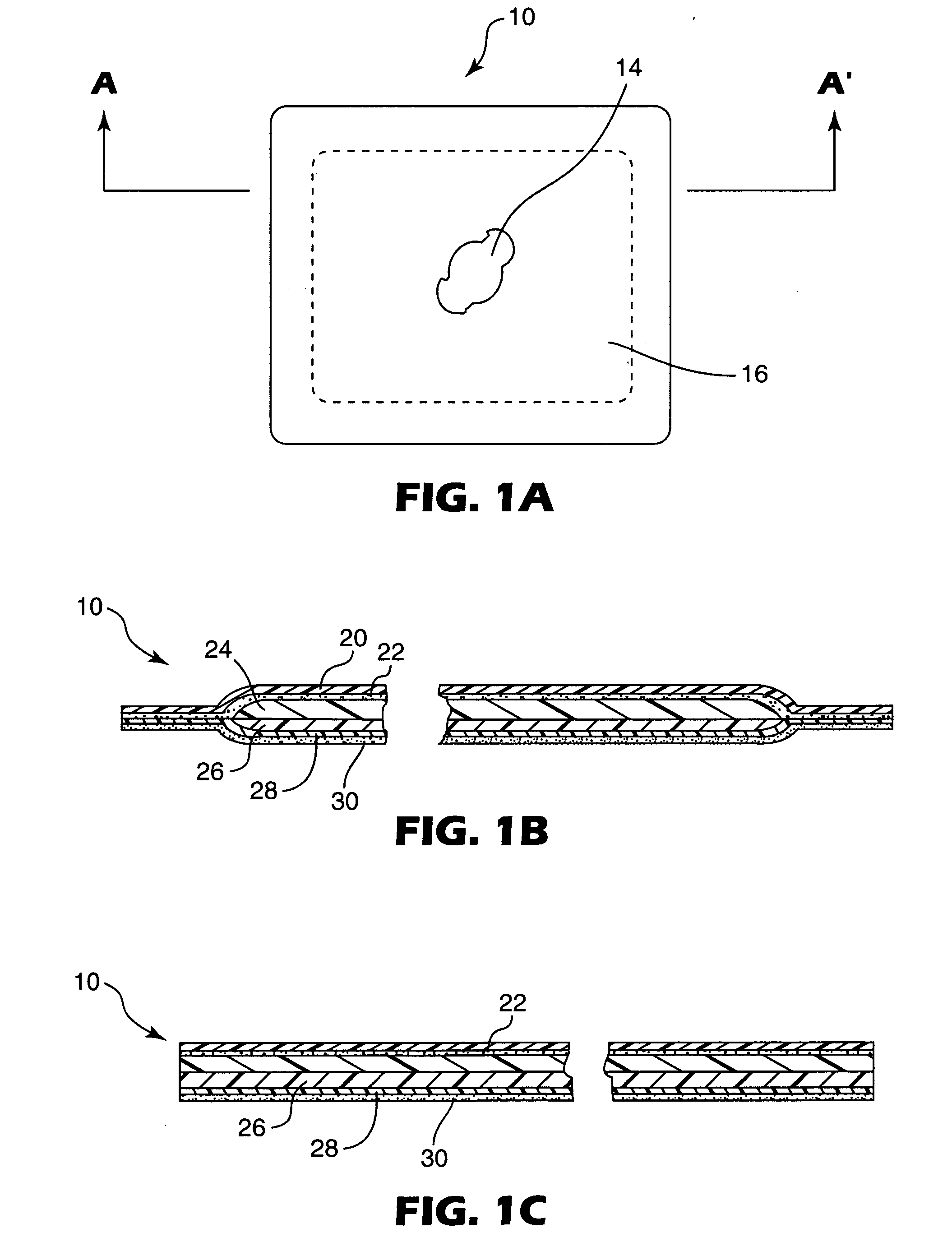

Multi-Layer Absorbent Wound Dressing

[0087] A multi-layer absorbent wound dressing having a backing layer, a first absorbent layer, a second absorbent layer, and a wound-facing layer was prepared by the following procedure.

[0088] The first absorbent layer precursor composition (Composition A) was prepared as follows. Acrylic acid (528 g, BASF, Mt. Olive, N.J.), 50% (w / w) sodium hydroxide solution (99 g, J. T. Baker, Philipsburg, N.J.), and 2-hydroxy-1-[4-(hydroxyethoxy)phenyl]-2-methyl-1-propanone (1.32 g, Ciba Specialty Chemicals Corp., Tarrytown, N.Y.) were added to a glass jar and mixed until dissolved. Methoxypolyethyleneglycol 400 acrylate (2470 g, “NK Ester-AM-90G”, Shin-Nakamura Chemical Co., Ltd., Japan) was added to the jar and mixed in by shaking the jar. Lauryl acrylate (198 g, Aldrich Chemical Co., Milwaukee, Wis.) and alpha-methylstyrene (3.3 g, Aldrich) were added and the entire composition was mixed by shaking the jar.

[0089] The second absorbent layer precursor comp...

example 2

Multi-Layer Absorbent Wound Dressing

[0093] A multi-layer absorbent wound dressing was prepared as described in Example 1, except that N-vinyl acetamide was substituted for the acrylic acid / sodium hydroxide components in the first absorbent layer precursor composition (Composition A) and this composition was prepared as follows.

[0094] N-Vinyl acetamide (600 g, Showa Denko, Japan), 2-hydroxy-1-[4-(hydroxyethoxy)phenyl]-2-methyl-1-propanone (1.2 g), and methoxypolyethyleneglycol 400 acrylate (2183 g) were added to a glass jar and mixed by shaking the jar until the N-vinyl acetamide was dissolved. Lauryl acrylate (210 g) and alpha-methylstyrene (3.0 g) were added and the entire composition was mixed by shaking the jar.

[0095] Also, the wound-facing layer in this example contained 40 holes / cm2 with each hole having a diameter of approximately 20 mils (0.51 mm). The Percent Void Area was calculated to be 7.8%.

[0096] The resulting completed multi-layer absorbent wound dressing material ...

example 3

Multi-Layer Absorbent Wound Dressing

[0097] A multi-layer absorbent wound dressing was prepared as described in Example 1, except that the sodium hydroxide solution component was not added to either Composition A or Composition B. The resulting completed multi-layer absorbent wound dressing material was cut into 10-cm×15-cm samples for test evaluations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com