Acoustical insulator for a vehicle

a technology of acoustical insulation and a vehicle, which is applied in the direction of weaving, instruments, transportation and packaging, etc., can solve the problems of delamination and failure risk of laminated shields and insulators, significant potential, and degrading adhesives and binders, and achieves the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

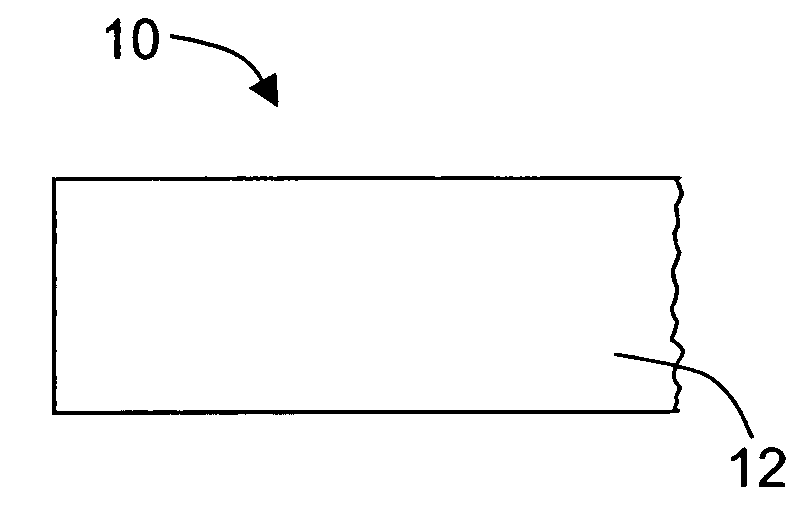

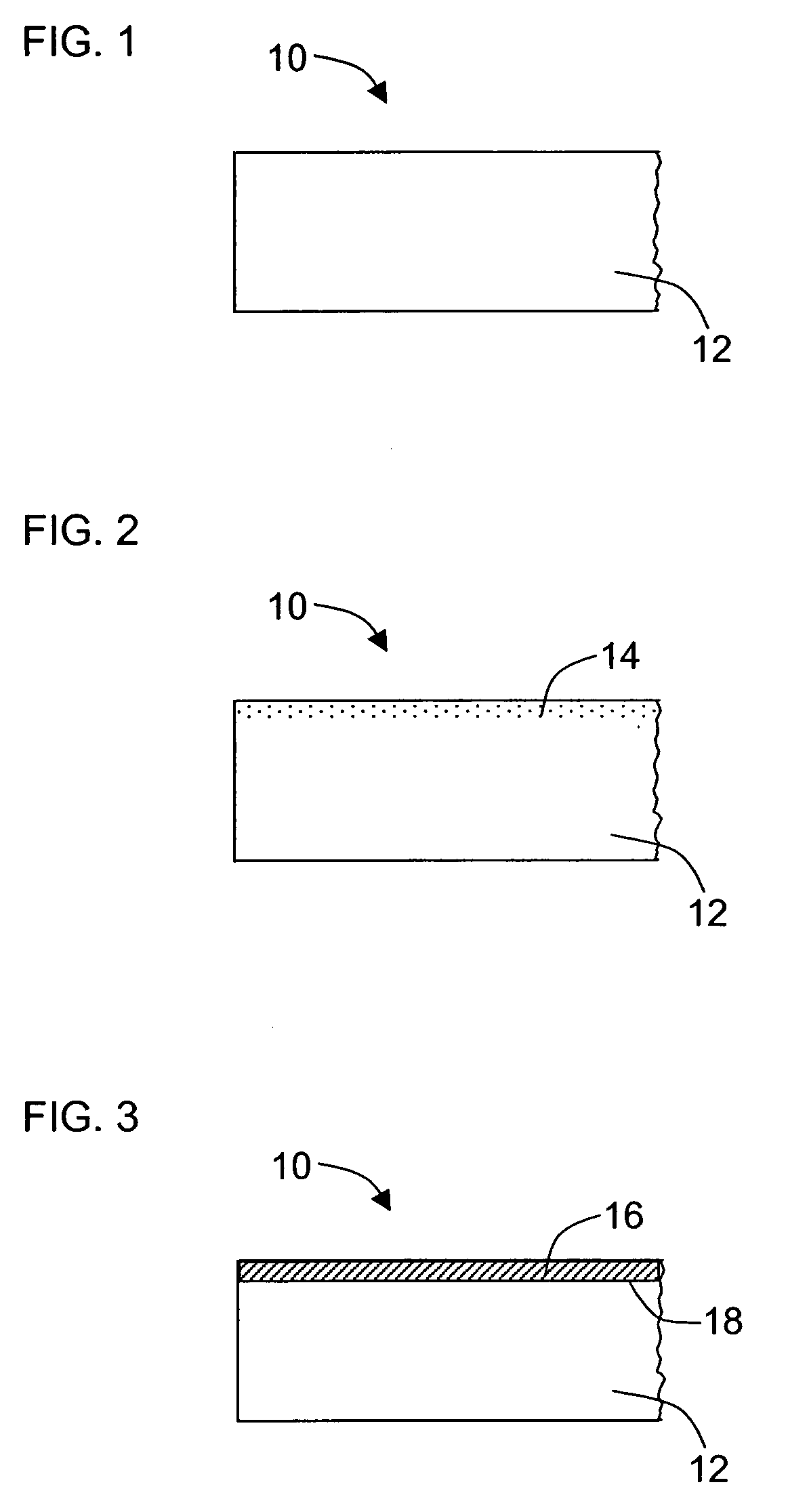

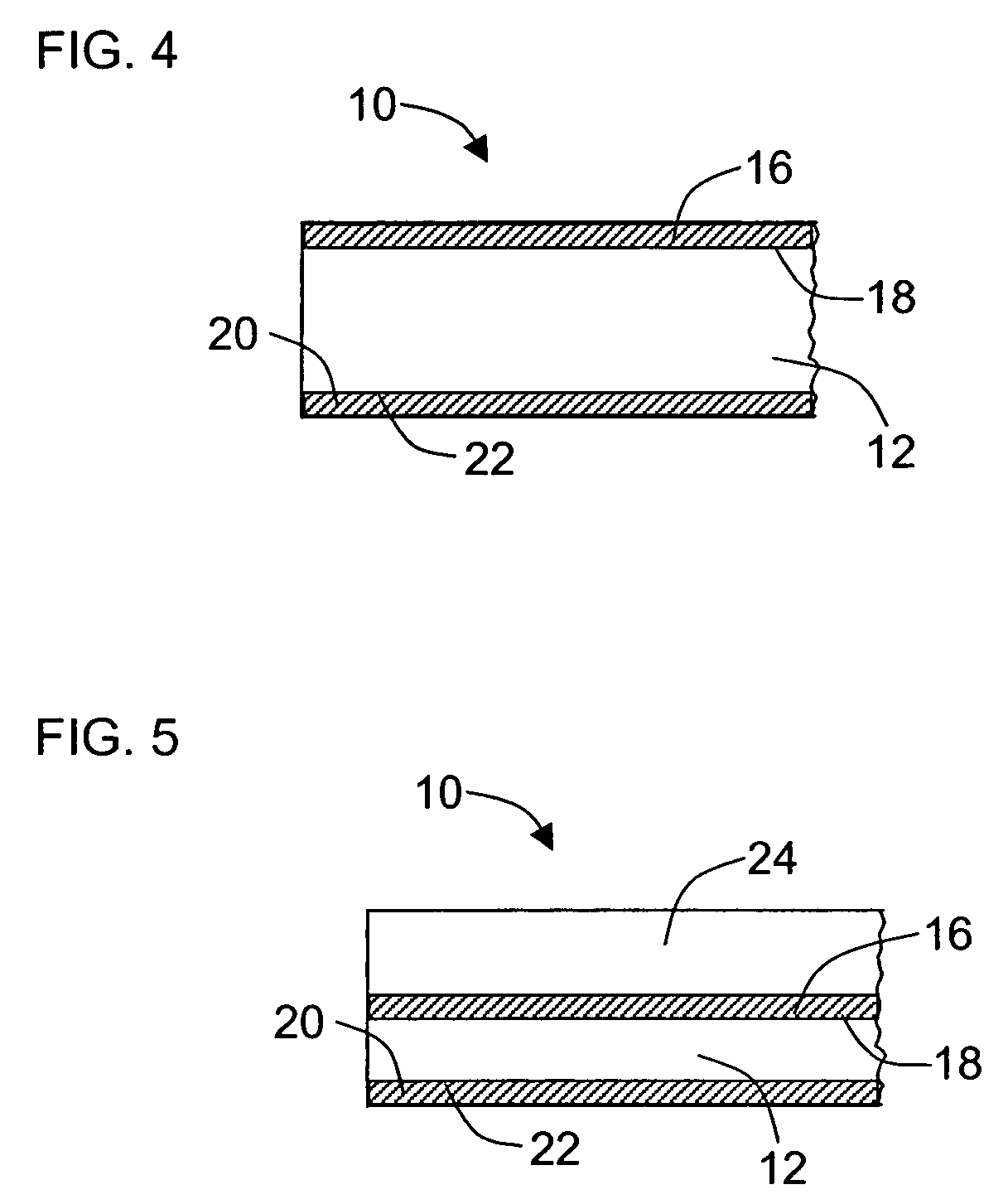

[0015] Reference is now made to FIG. 1 showing a first embodiment of the insulator 10 of the present invention. The insulator 10 comprises an acoustical and thermal insulating layer 12 of polymer fiber and natural fiber. More specifically, a single, nonlaminated layer 12 is provided with the necessary mechanical strength and rigidity to allow easy installation and the desired acoustical and thermal insulating properties. Advantageously, all of these benefits are achieved in a light weight insulator 10 which may even be used in compact vehicles where fuel economy concerns lead manufacturers to seek weight savings wherever possible. The insulator 10 may, for example, be used as a pillar, door, quarter panel, trunk, roof, wheel house and floor pan liner in a motor vehicle.

[0016] The polymer fiber and natural fiber blend is not foamed and typically is a nonwoven material. The polymer fiber may be polyester, polypropylene, polyethylene, rayon, nylon and any mixtures thereof and the natu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com