Ion channel modulating compounds and uses thereof

a technology of ion channel and modulating compounds, which is applied in the field of ion channel modulating compounds, can solve the problems of increasing mortality in patients with myocardial infarction, no satisfactory pharmacotherapy for the treatment and/or prevention of ventricular fibrillation during acute, and the use of antiarrhythmic compounds, so as to relieve or forestall the sensation of pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

(±)-Trans-[2-(4-Morpholinyl)-1-(1-Naphthenethoxy)]Cyclohexane Monohydrochloride

(Compound #2)

[0170] (i) The starting trans-aminocyclohexanol is prepared according to example 1.

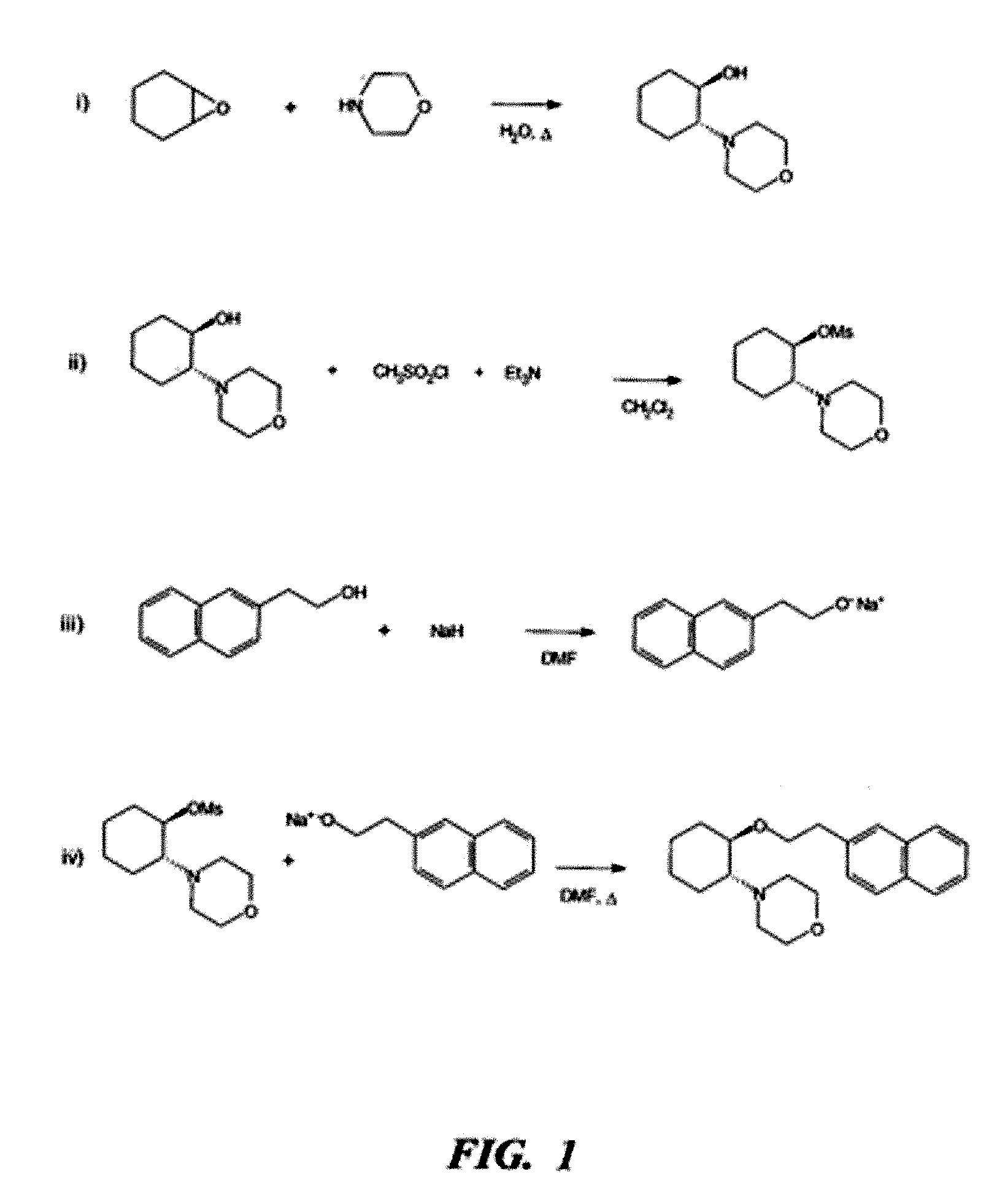

[0171] (ii) To a chilled (0ºC) solution of (±)-trans-[2-(4-morpholinyl)]cyclohexanol (6.0 g, 32 mmol) and triethylamine (6.8 mL, 48 mmol) in dichloromethane (100 mL) was added via cannula a solution of methanesulfonyl chloride (3.10 mL, 40 mmol) in dichloromethane (50 mL). The addition was completed in 10 min., the reaction mixture was stirred for another hour at 0ºC and then at room temperature for 4 hours. The dichloromethane mixture was washed with water (2 x 50 mL) and the combined aqueous washings back extracted with dichloromethane (50 mL). The combined organic layers were dried over sodium sulfate and concentrated in vacuo to provide 9.0 g of the crude mesylate.

[0172] (iii) To sodium hydride, 80% oil dispersion, previously washed with hexanes (3 x 20 mL) (1.30 g, 51.6 mmol), in dry dimethylformamide (...

example 3

(±)-Trans-[2-(4-Morpholinyl)-1-(4-Bromophenethoxy)]Cyclohexane Monohydrochloride

(Compound #3)

[0173] (i) The starting trans-aminocyclohexanol is prepared according to example 1.

[0174] (ii) To a chilled (0ºC) solution of (±)-trans-[2-morpholinyl)]cyclohexanol (3.0 g, 16.2 mmol) and triethylamine (3.4 mL, 24 mmol) in dichloromethane (25 mL) was added via cannula a solution of methanesulfonyl chloride (1.55 mL, 20.0 mmol) in dichloromethane (25 mL). The addition was completed in 5 min., the reaction mixture was stirred for another hour at 0ºC and then at room temperature for 2 hours. The reaction mixture was diluted with dichloromethane (50 mL) and washed with water (2 x 50 mL) and the combined aqueous washings back extracted with dichloromethane (25 mL). The combined organic layers were dried over sodium sulfate and concentrated in vacuo to provide 4.7 g of the crude mesylate.

[0175] (iii) To sodium hydride, 80% oil dispersion, previously washed with hexanes (3 x 10 mL), (0.62 g, 25....

example 4

(±)-Trans-[2-(4-Morpholinyl)-1-[2-(2-Naphthoxy)Ethoxy)]Cyclohexane Monohydrochloride

(Compound #4)

[0176] (i) The starting trans-aminocyclohexanol is prepared according to example 1.

[0177] (ii) To a chilled (0ºC) solution of (()-trans-[2-(4-morpholinyl)]cyclohexanol (3.0 g, 16.2 mmol) and triethylamine (3.4 mL, 24 mmol) in dichloromethane (50 mL) was added via cannula a solution of methanesulfonyl chloride (1.55 mL, 20.0 mmol) in dichloromethane (50 mL). The addition was completed in 10 min., the reaction mixture was stirred for another hour at 0ºC and then at room temperature for 4 hours. The dichloromethane mixture was washed with water (2 x 50 mL) and the combined aqueous washings back extracted with dichloromethane (50 mL). The combined organic layers were dried over sodium sulfate and concentrated in vacuo to provide 4.3 g (100% yield) of the crude mesylate.

[0178] (iii) To sodium hydride, 80% oil dispersion, previously washed with hexanes (3 x 10 mL), (0.7 g, 29 mmol) in dry d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pKa | aaaaa | aaaaa |

| pKa | aaaaa | aaaaa |

| pKa | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com