Process flow control circuit

a flow control and circuit technology, applied in the direction of pump control, positive displacement liquid engine, non-positive displacement fluid engine, etc., can solve the problems of increased differential pressure, trouble, and drop in the amount of fluid flow transmitted through the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

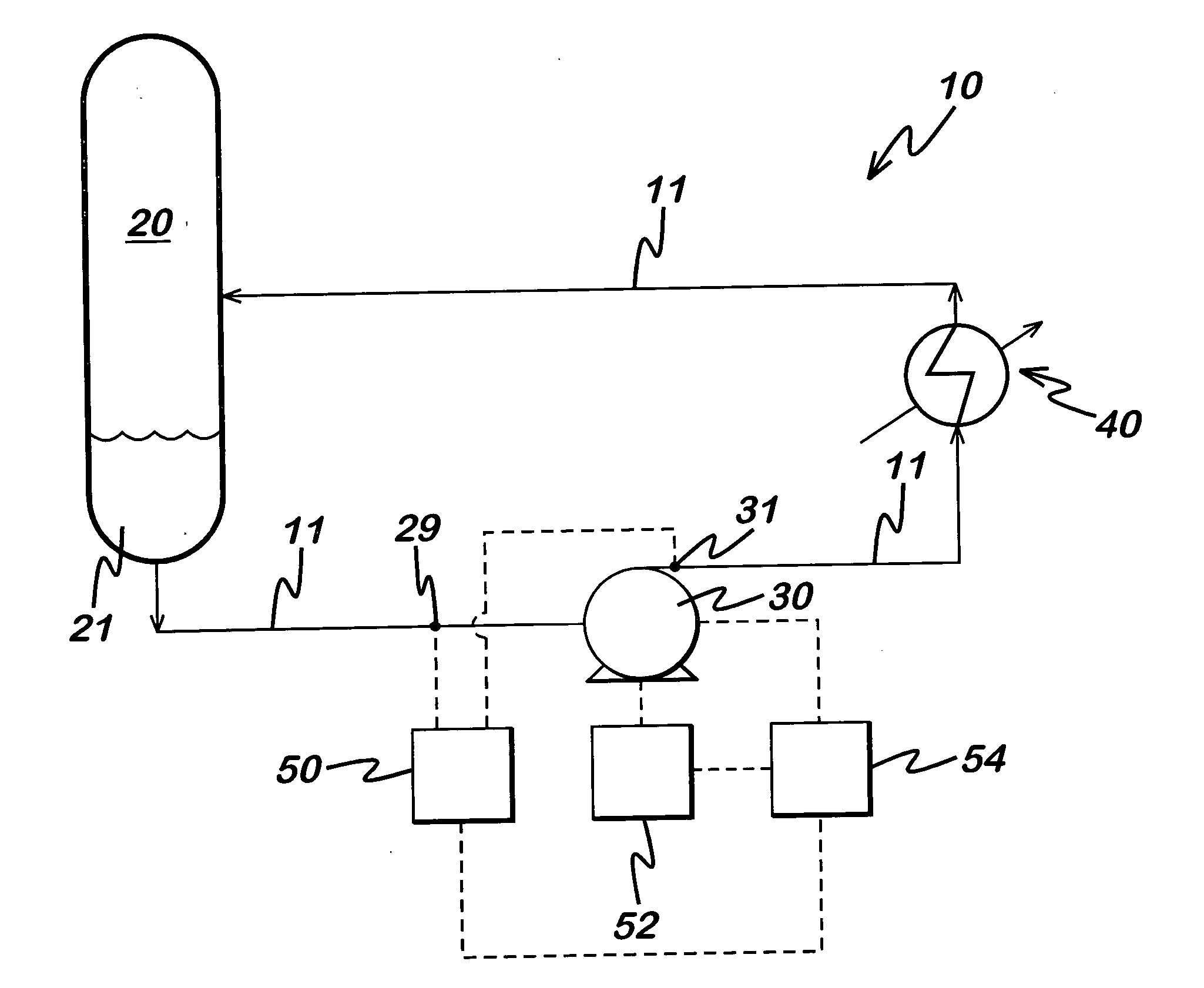

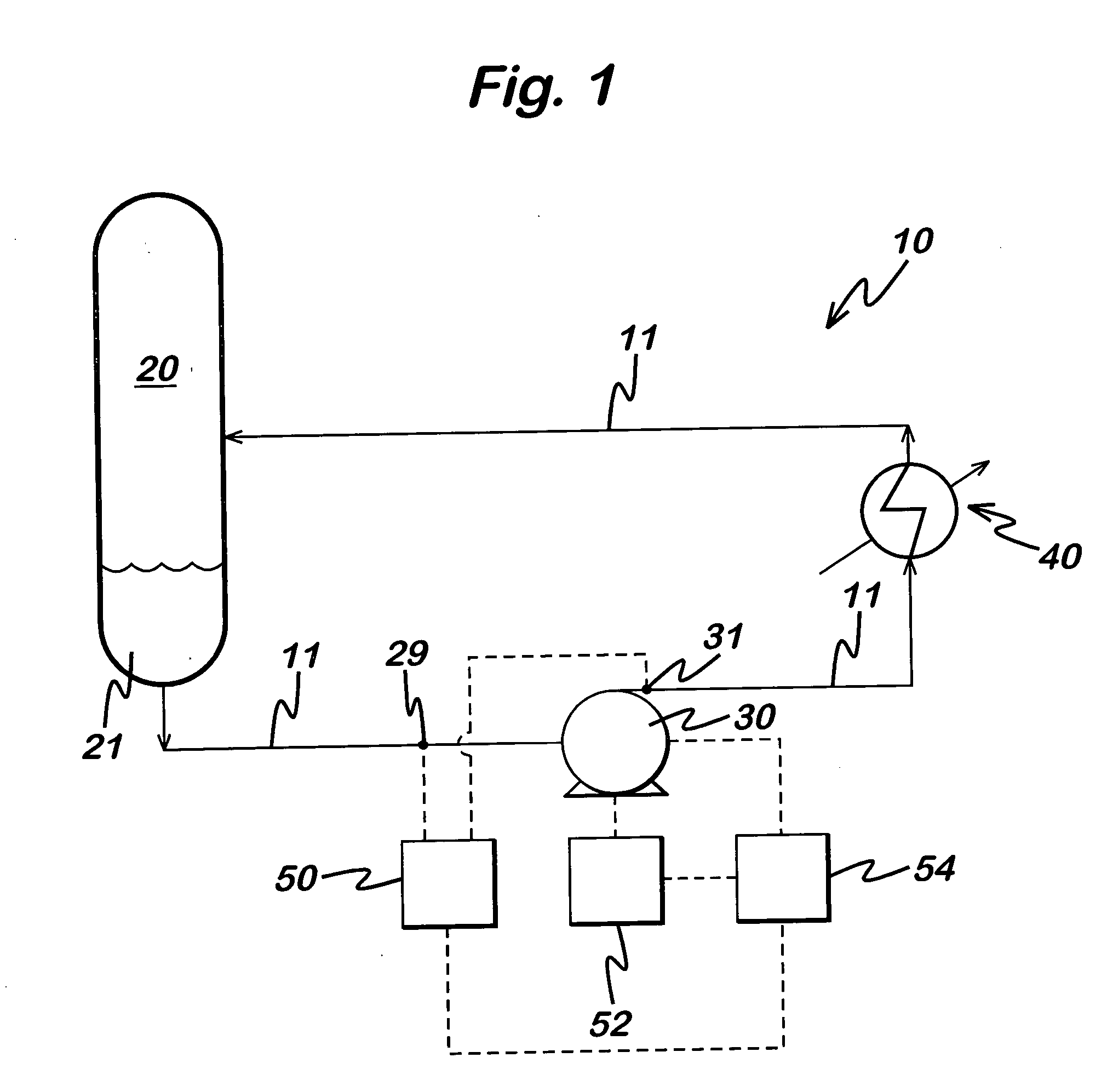

[0013] With reference to the drawing herein, a flow circuit 10 comprising, piping 11, a vessel 20, a flow transfer device 30, and a fluids processing device 40 is shown in FIG. 1. The fluids processing device 40 is shown as a heat exchanger with the process fluid of the flow circuit 10 passing through its tube side. However, any number of other process components could comprise the fluids processing device 40, such as a filter, dryer, separator, or coalescer. Likewise, these substitute elements, or other like elements, could also take the place of the vessel 20.

[0014] The specific elements of the flow circuit 10 as illustrated in FIG. 1 are not critical to the invention, but instead are shown for illustration. The present invention will operate with the specific items shown in FIG. 1, or with additional fluids handling hardware, such as other vessels, exchangers, and the like, or fewer items as shown. Similarly the fluid transfer device 30 is shown as a centrifugal pump, but could ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com