Wind turbine blade with carbon fibre tip

a carbon fibre tip and wind turbine technology, applied in the field of wind turbine blades, can solve the problems of high dead load moment, high fatigue resistance, increased problem with the length of the blade, etc., and achieve the effect of reducing the load on the turbine hub, reducing the weight, and reducing the dead load momen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

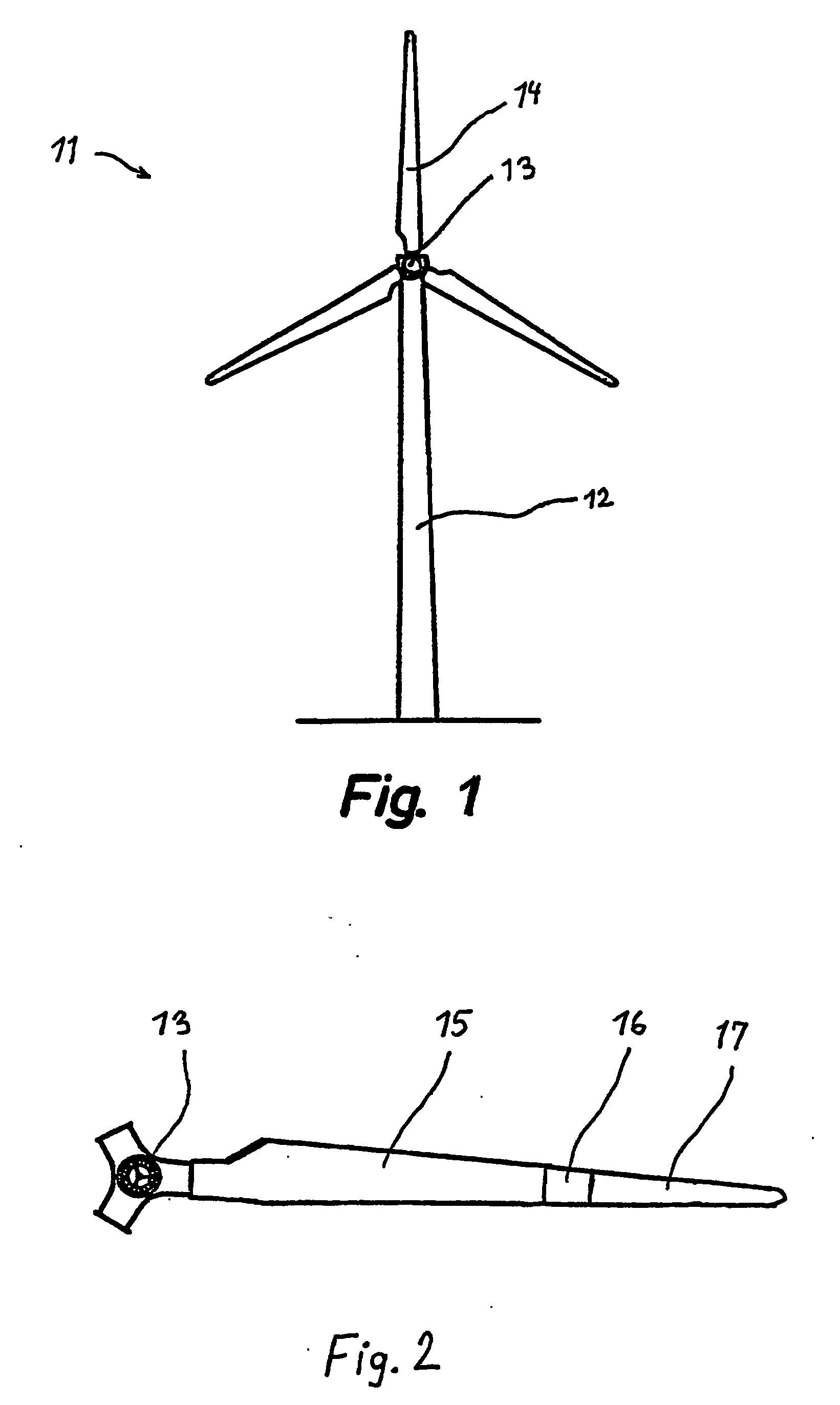

[0030]FIG. 1 shows a modern wind turbine including a tower 12 with a hub 13 and three wind turbine blades 14 extending from the hub.

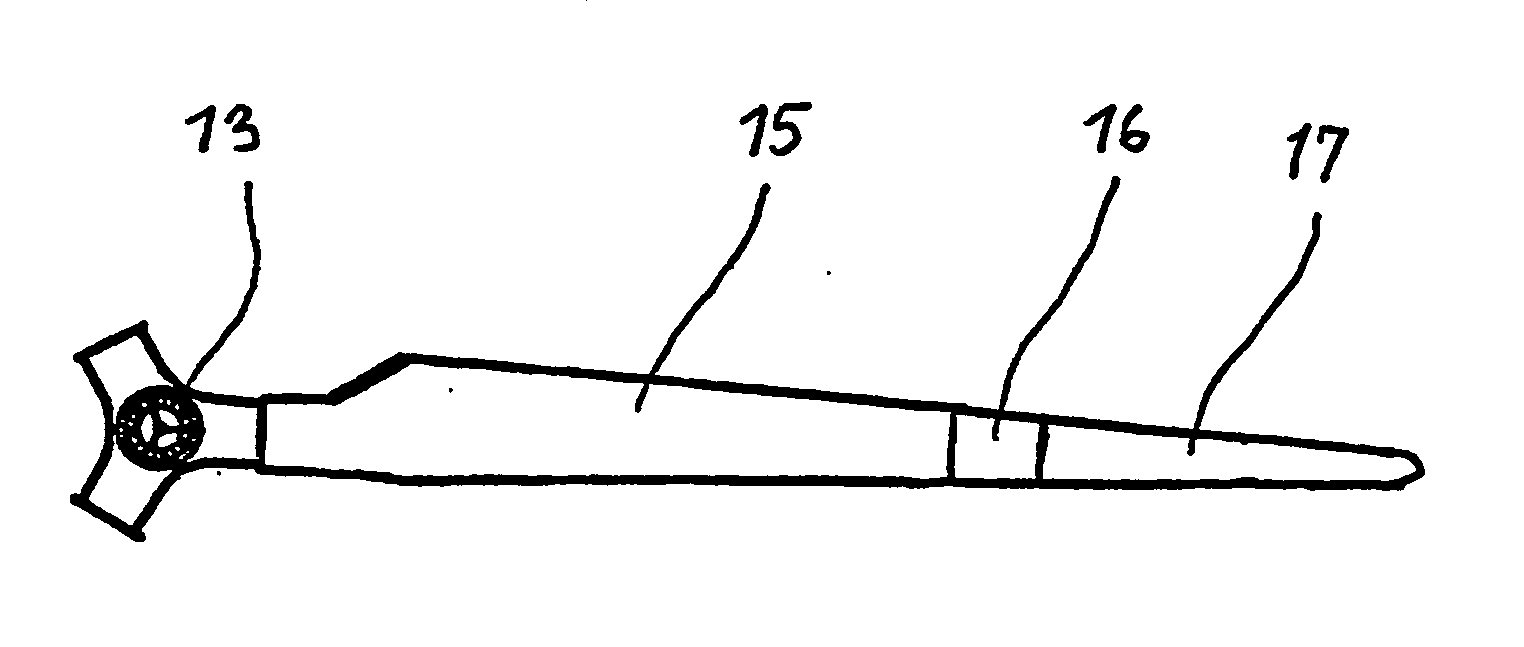

[0031]FIG. 2 illustrates an embodiment of a wind turbine blade according to the invention, in which an inner end portion 15 including the blade root is made substantially from fibre glass-reinforced polymer, and in which an outer end portion 17 including the blade tip is made substantially from carbon fibre-reinforced polymer. Bordering on the inner end portion 15 the outer end portion 17 includes a transition zone 16, in which the carbon fibres are gradually replaced by glass fibres such that a gradual change in the stiffness of the blade is obtained.

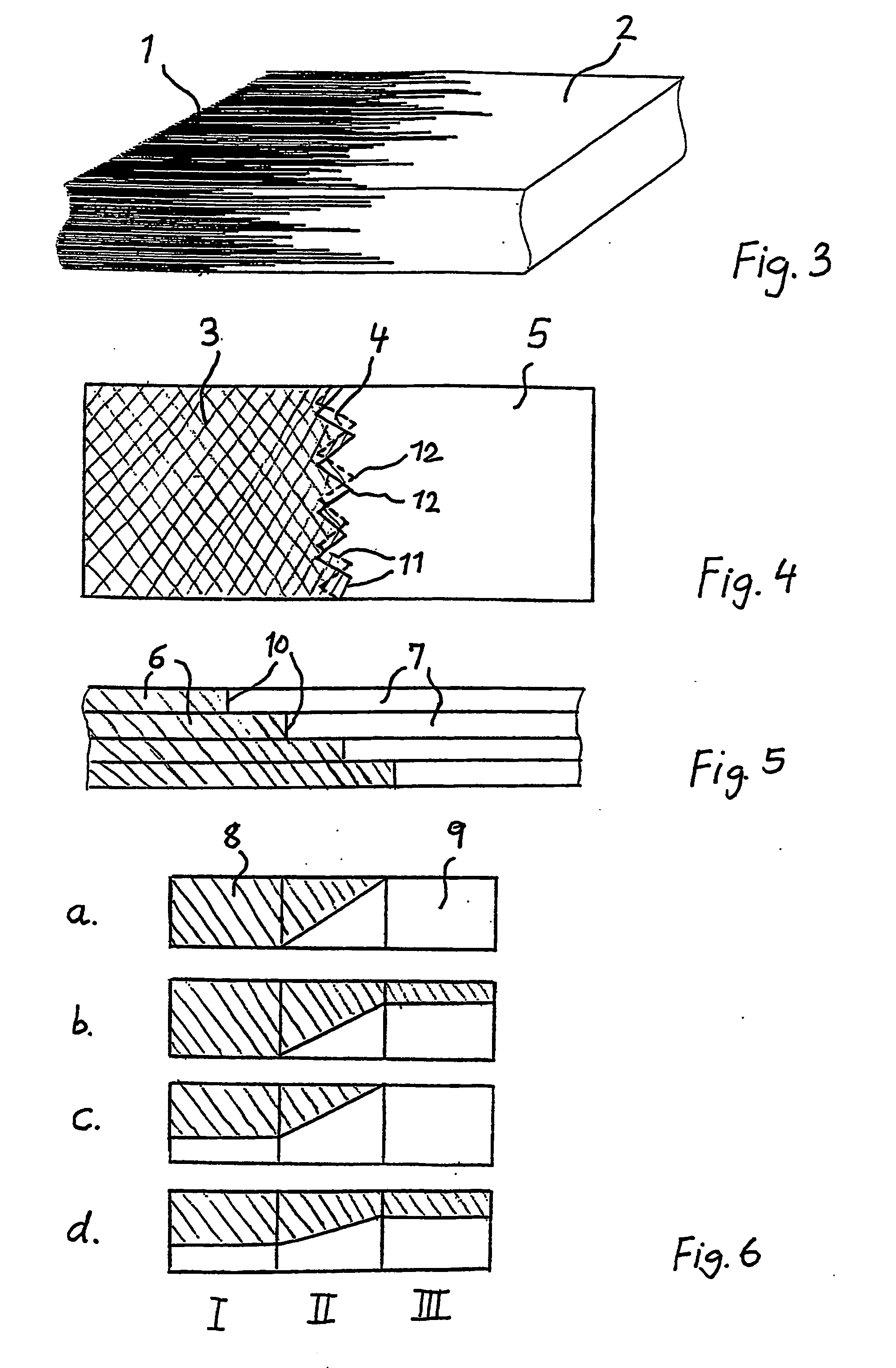

[0032]FIG. 3 is a sectional view of the transition zone, in which the quantitative ratio of carbon fibres to glass fibres gradually changes. The carbon fibres 1 extend from the left-hand side of the sectional view in form of bundles or single-fibres of different lengths. The glass fibres 2 are not visibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com