Method of using intrinsically conductive polymers with inherent lubricating properties, and a composition having an intrinsically conductive polymer, for protecting metal surfaces from galling and corrosion

a technology of intrinsically conductive polymers and lubricating properties, which is applied in the direction of electrolytic coatings, corrosion prevention, fastening means, etc., can solve the problems of not providing corrosion protection, patents do not disclose dry lubricating processes, and cannot disclose methods of using intrinsically conductive polymers with inherent lubricating properties. , to achieve the effect of improving the adhesion of the dry film, enhancing anti-corrosion properties, and high stability of the poly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

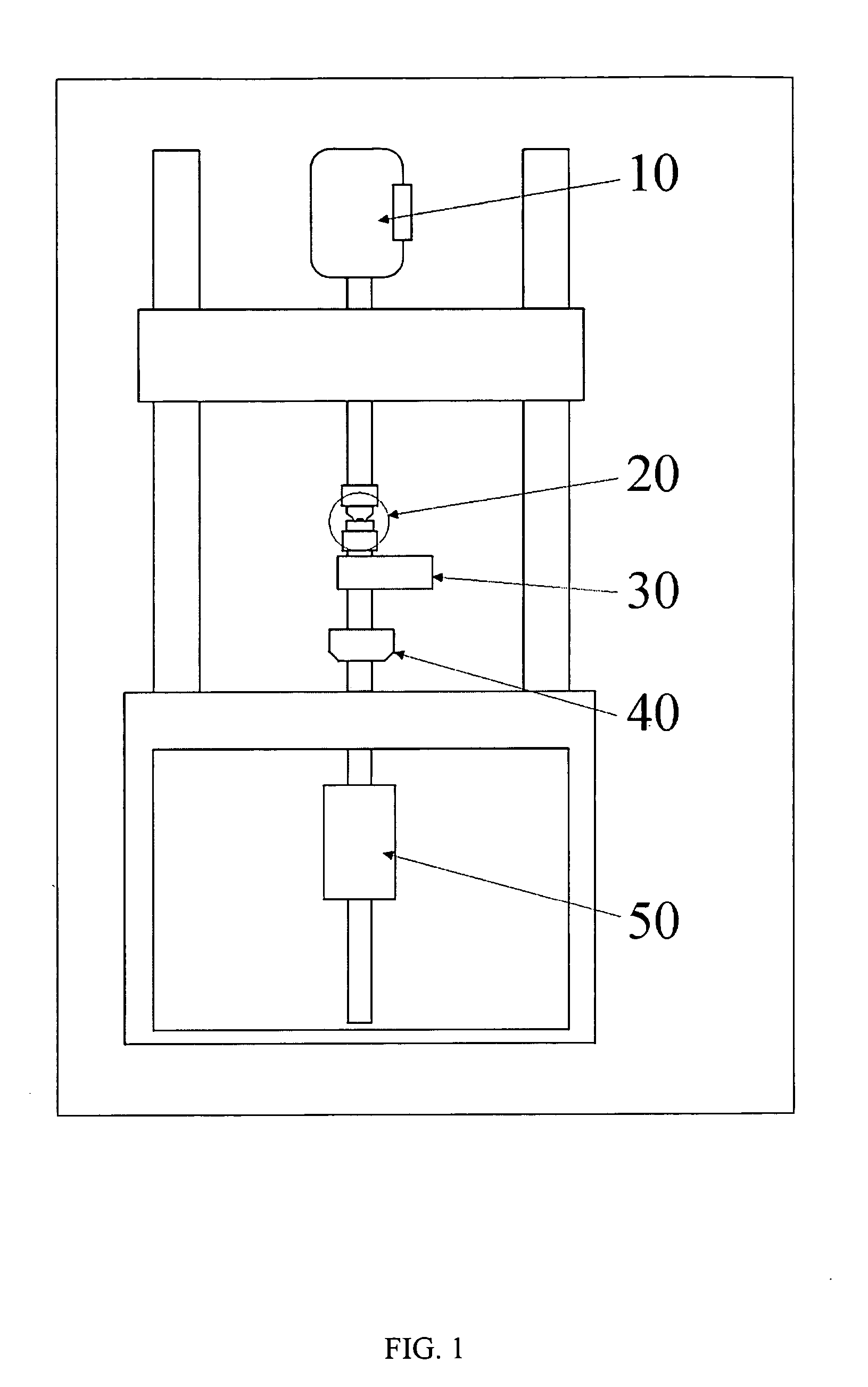

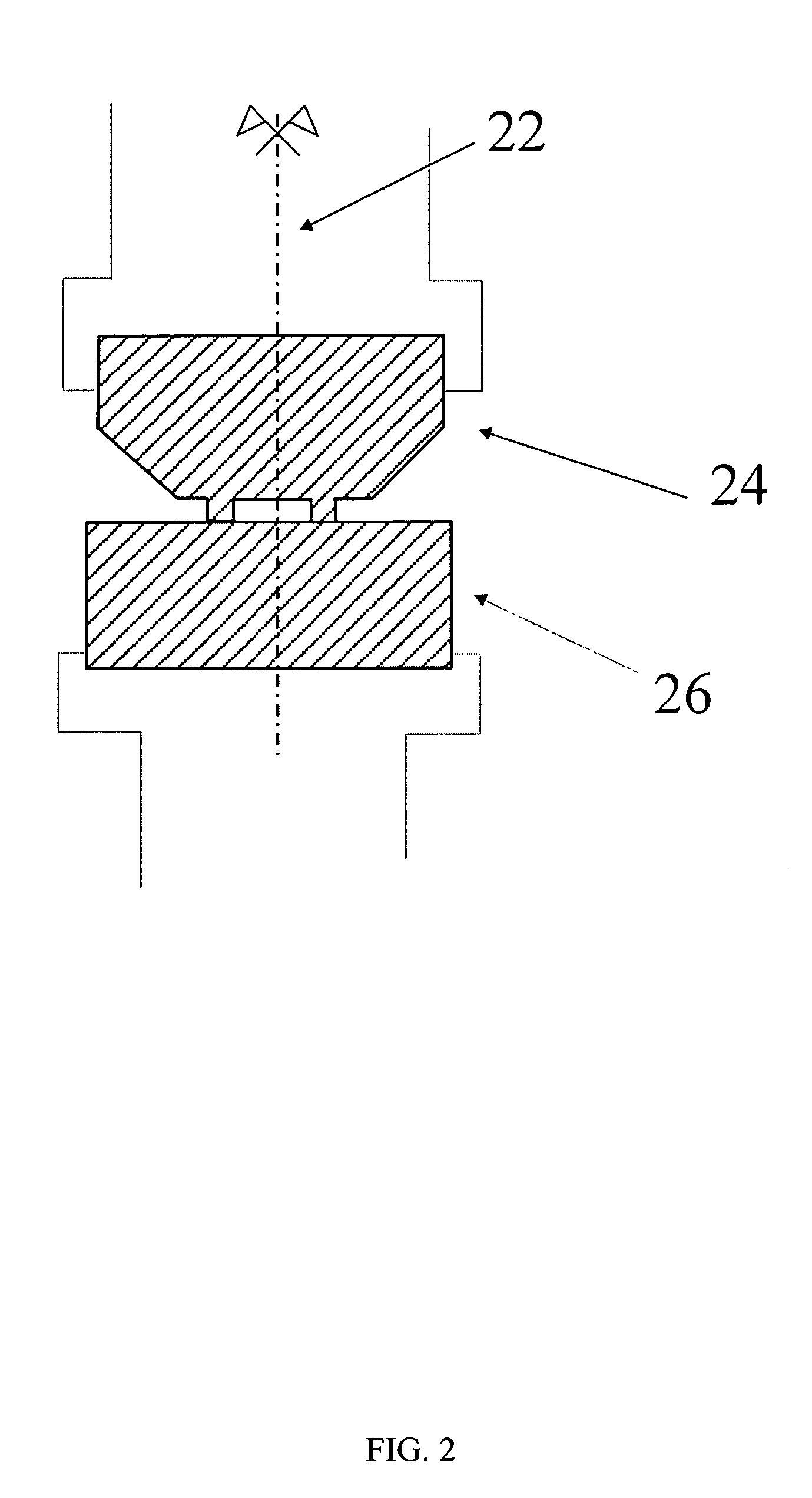

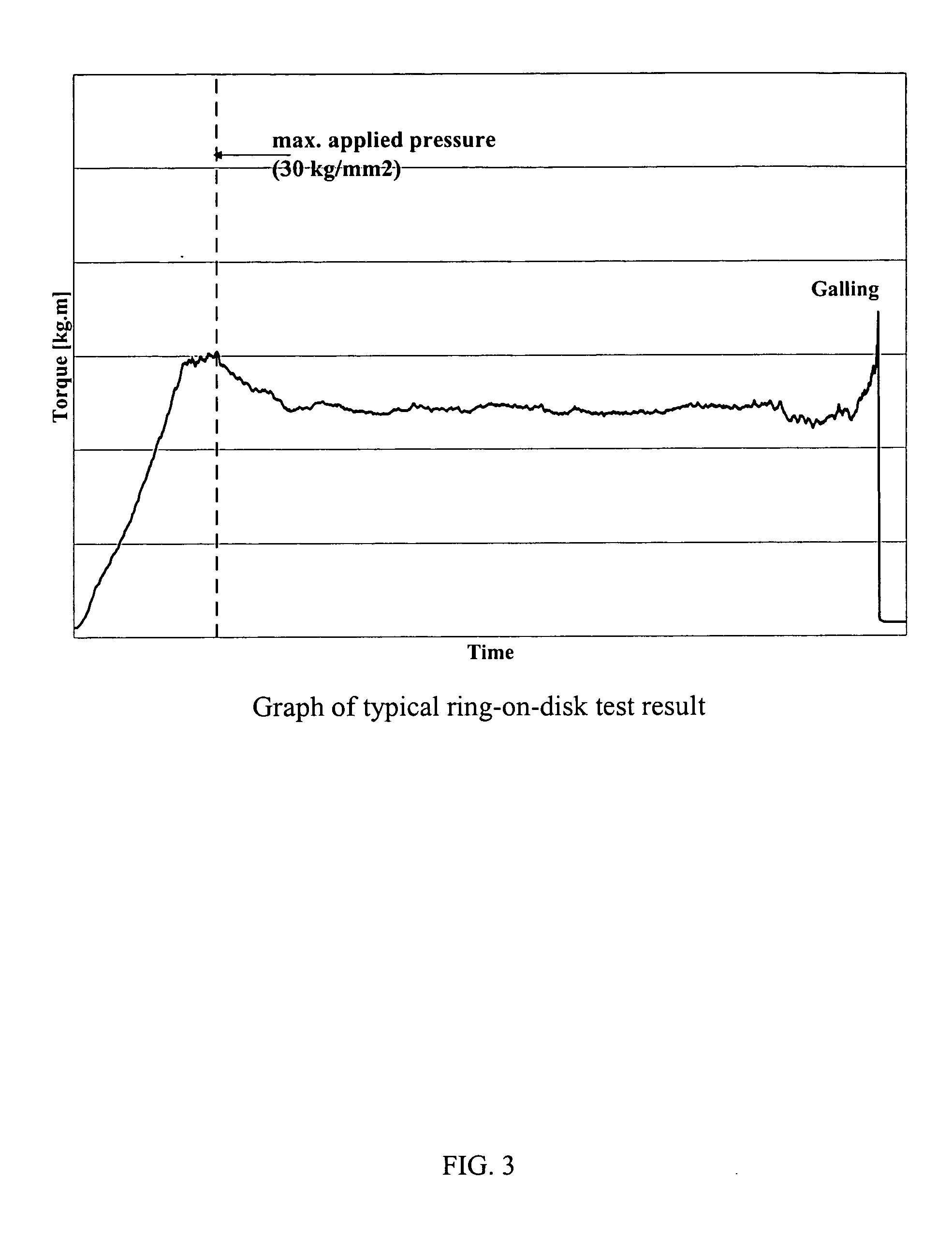

[0042] The present invention relates to composition, preparation, and application of a dry film to steel and other metal surfaces, such as the surface of a threaded joint in an oil pipe, in order to protect the metal against galling under high applied torque, as well as to confer resistance to corrosion.

[0043] The dry film of the invention comprises a solid lubricant selected from those commonly used for lubrication purposes, such as molybdenum disulfide, graphite, or mixtures thereof; and a binding intrinsically conductive polymer such as polyaniline, polyprrole, or copolymers or modifications of these polymers.

[0044] Polyaniline used in the dry film may be prepared according to various methods, such as those described by Ponzio et al. (Polym. Int 50 (2001) 1180-1185), Cao et al. (Polymer 30 (1989) 2305-2311), Stejskal et al. (Synth. Met. 105 (1999) 195-202), Sun et al. (Synth. Met. 84 (1997) 99-100), Mattoso et al. (Synth. Met. 68 (1994)1-11), Singh et al. (Polymer 38 (1997) 489...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com