Splined connection

a technology of splined connection and lubricating surface, which is applied in the direction of couplings, gearings, hoisting equipment, etc., can solve the problems of long period of good lubrication of the surface of the connection region, and achieve the effects of preventing lubricant leakage, preventing ingress of dirt and ambient particles, and preventing obliqueness and radial displacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

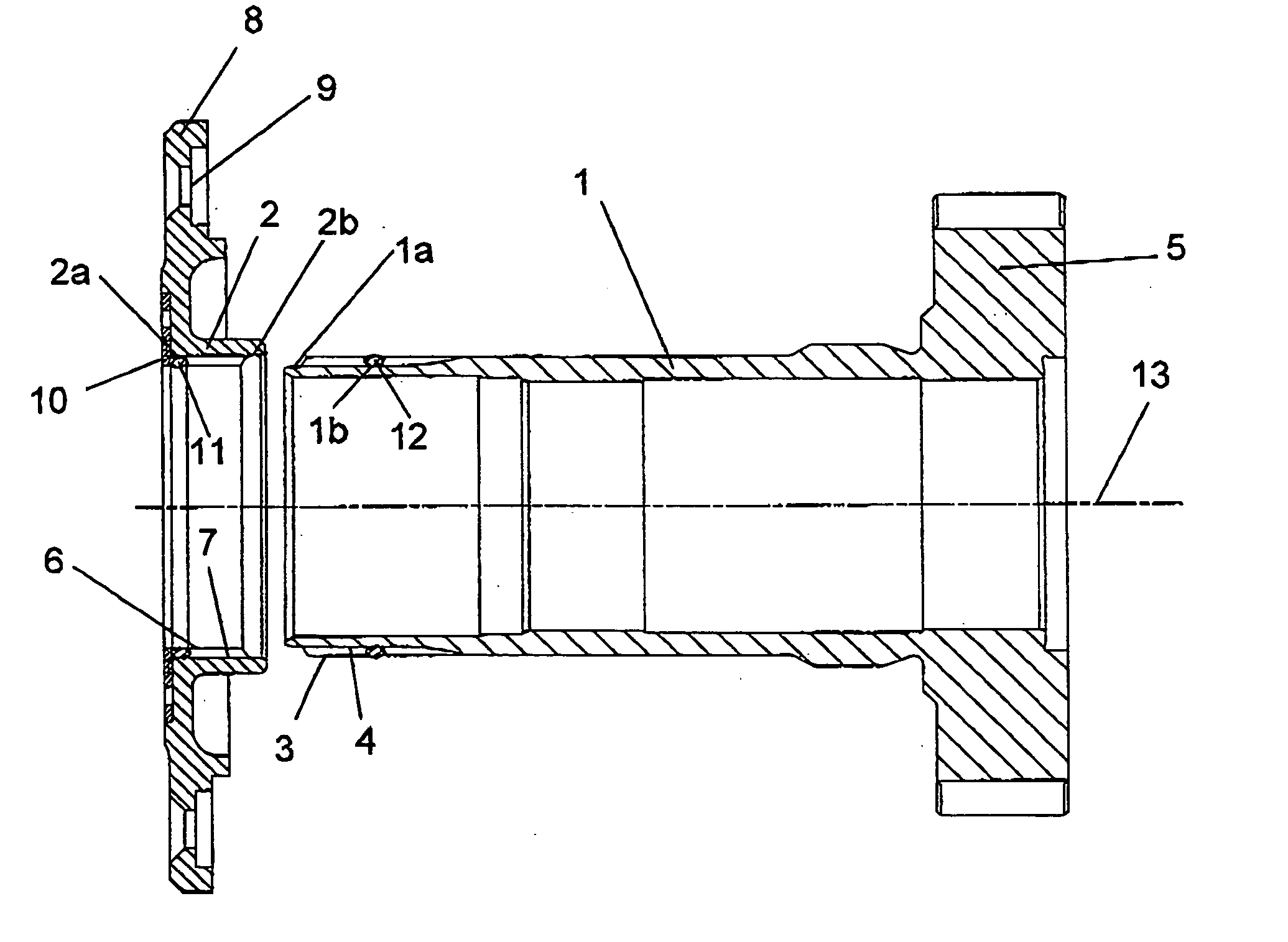

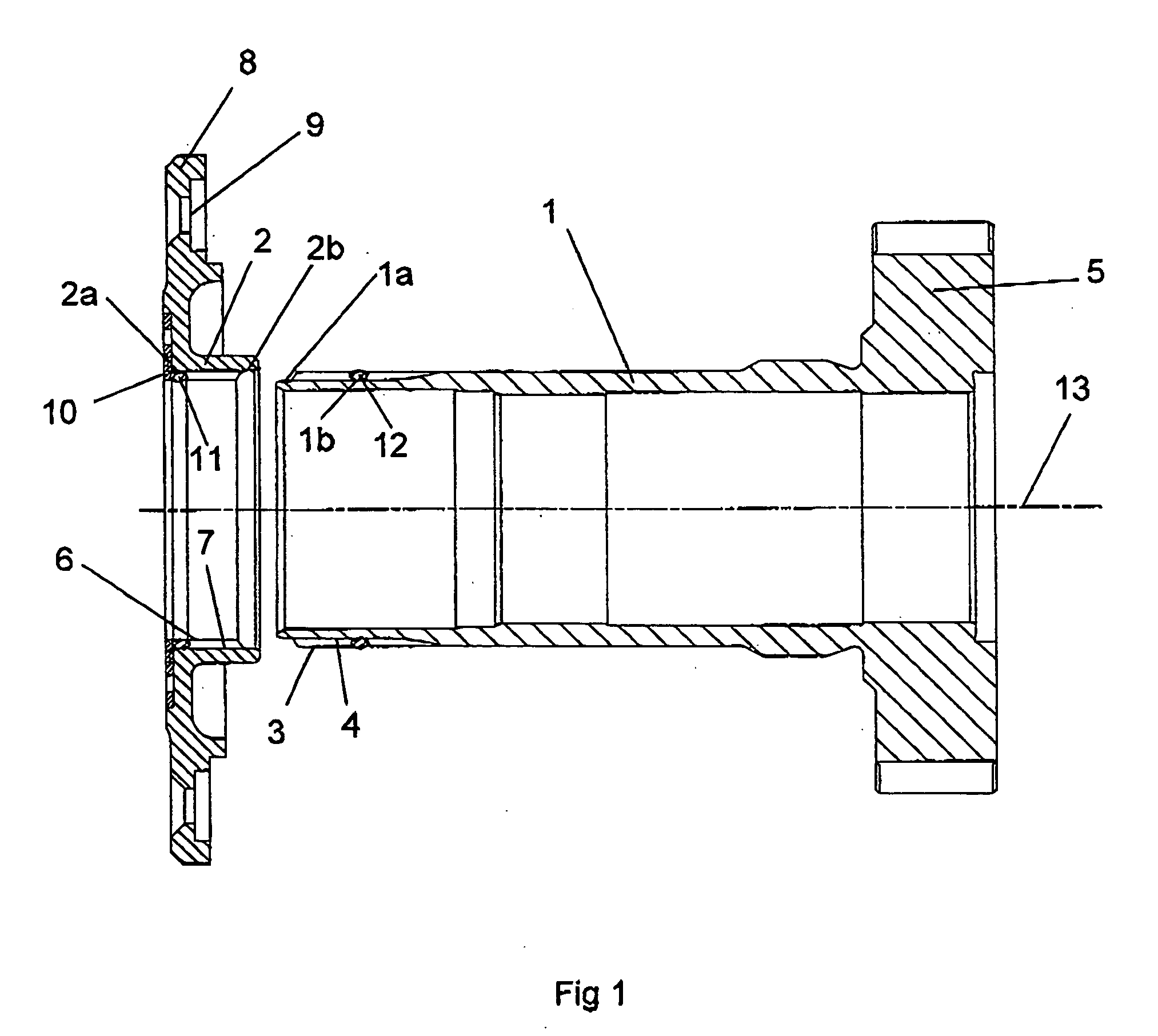

[0016]FIG. 1 depicts a splined connection in an unassembled state. The splined connection comprises mainly two parts, namely a shaft 1 and a hub 2. The shaft 1 has at one end splining, which in a conventional manner comprises a multiplicity of longitudinal protruding ridges 3 and intermediate grooves 4 between the ridges. The ridges 3 and grooves 4 are usually arranged at uniform intervals round the circumference of the shaft 1. At an opposite end, the shaft 1 comprises a firmly attached gearwheel 5. In the case depicted, the shaft 1 is hollow. The splined connection comprises a hub 2 which has internally arranged splining. The splining of the hub is likewise provided in a conventional manner with a multiplicity of ridges 6 and intermediate grooves 7. The ridges 6 and grooves 7 of the hub are adapted to being fitted in engagement with the ridges 3 and grooves 4 of the shaft so as to provide a connection causing the shaft 1 and hub 2 to rotate together in the splined connection regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com