Button

a button and button body technology, applied in the field of buttons, can solve the problems of insufficient cutting of denim fabric between the tip end of the flare and the concave portion of the button body, the inability to utilize the button body attachment structure, and the difficulty of attachment, so as to achieve the effect of easy pressing, increased separation force, and easy cutting of fabri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

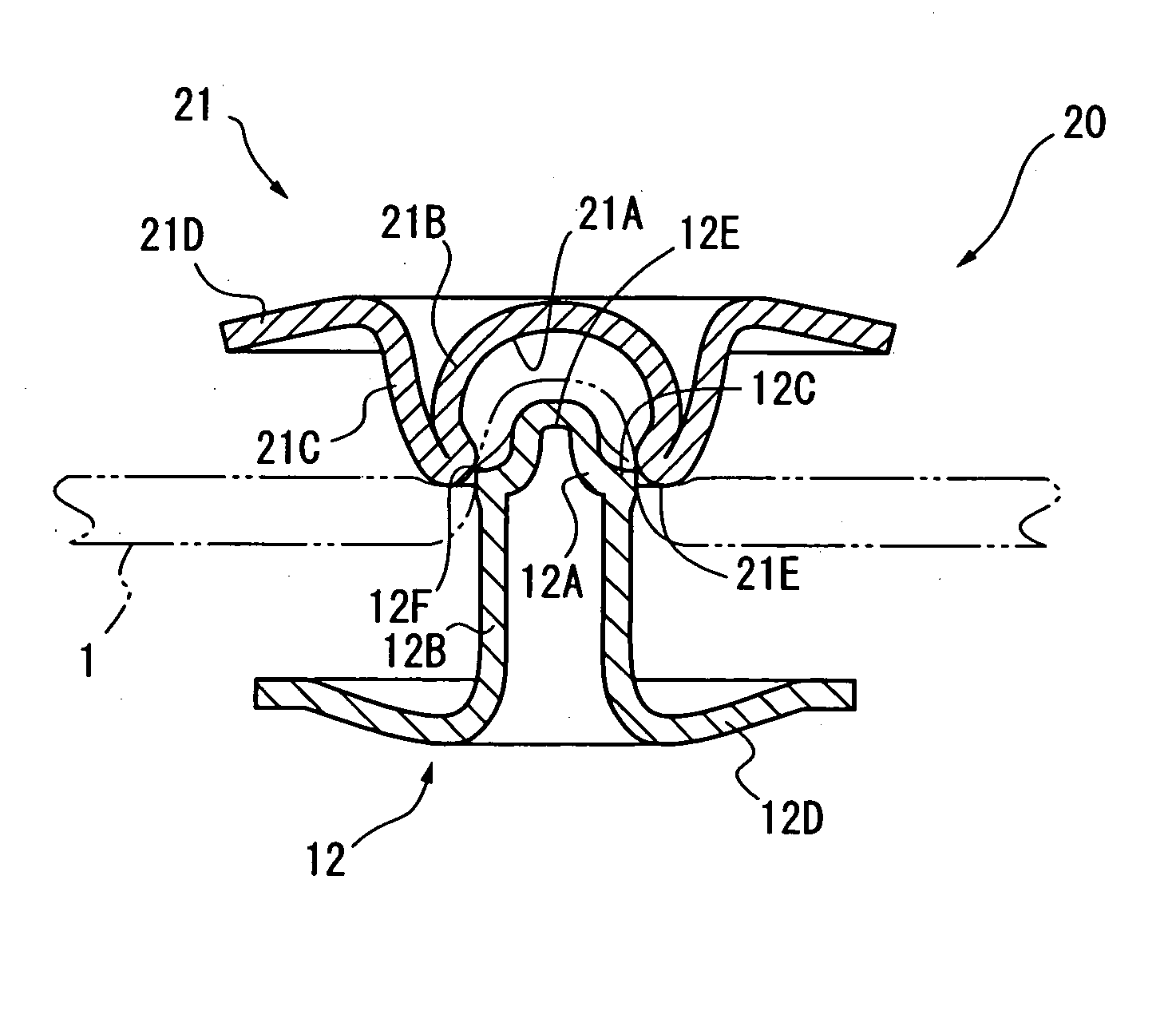

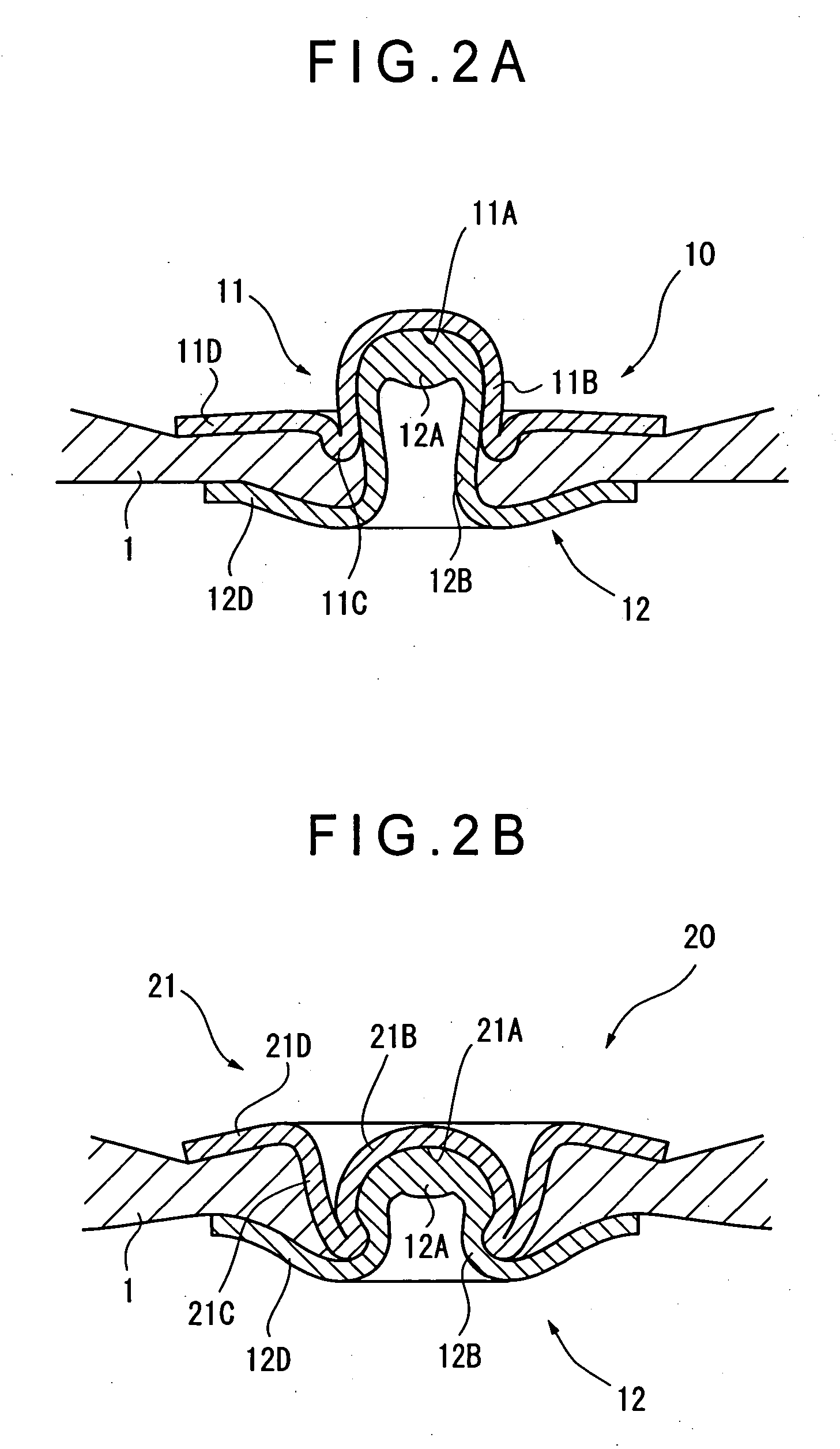

[0043]FIG. 1A is a cross section showing a

[0044] In FIG. 1A, a button 10 has a button body 11 and a fixture 12 attached to each other with a fabric 1 interposed therebetween.

[0045] The button body 11 is called F-bar and has a structure identical to the button body shown in FIG. 4B. The button body 11 is made of aluminum, iron, stainless steel alloy, copper alloy including brass or other kind of metals or alloys by an appropriate processing such as press working.

[0046] The button body 11 has a structure in which a center portion 11B provided with a concave portion 11A as a housing, a folded portion 11C slightly folded back from an edge of an opening end as an insertion end of the center portion 11B, a flange 11D extending straight from the folded portion 11C toward the outside are integrally molded.

[0047] The center portion 11B is formed to have a cylindrical shape with a bottom face, and the inner side thereof is the concave portion 11A. The concave portion 11A has a substantiall...

second embodiment

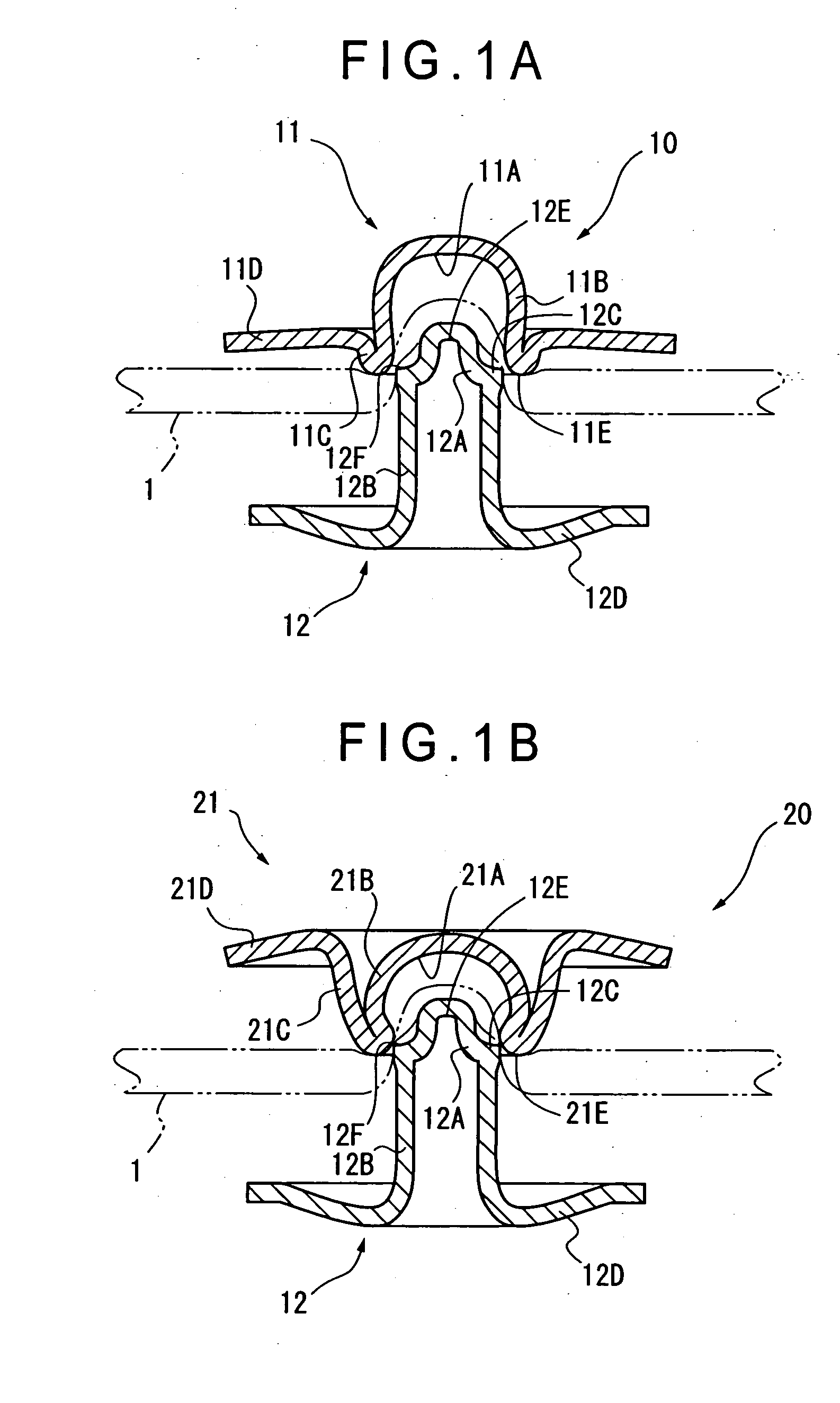

[0067]FIG. 1B shows a cross section showing a

[0068] In FIG. 1B, a button 20 has a button body 21 and the fixture 12 attached to each other with the fabric 1 interposed therebetween.

[0069] The button body 21 is called F-bar and has the same structure as the button body shown in FIG. 4A. The button body 21, as the button body 11 in the first embodiment, is made of aluminum, iron, stainless steel alloy, copper alloy including brass, or other kind of metals or alloys by an appropriate processing such as press working, and has a structure in which a center portion 21B provided with a concave portion 21A as a housing, a folded portion 21C slightly folded back from an opening end of the center portion 21B and the flange 21D extending from the folded portion 21C toward the outside are integrally molded.

[0070] The center portion 21B is formed to have a cylindrical shape with a bottom face, and the inner side thereof is the concave portion 21A. The concave portion 21A has a curved shape wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com