Probe card

a technology of a probe card and a spherical plate, which is applied in the direction of measurement devices, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of reducing throughput, requiring a long time, and unable to completely suppress the stress generated by thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

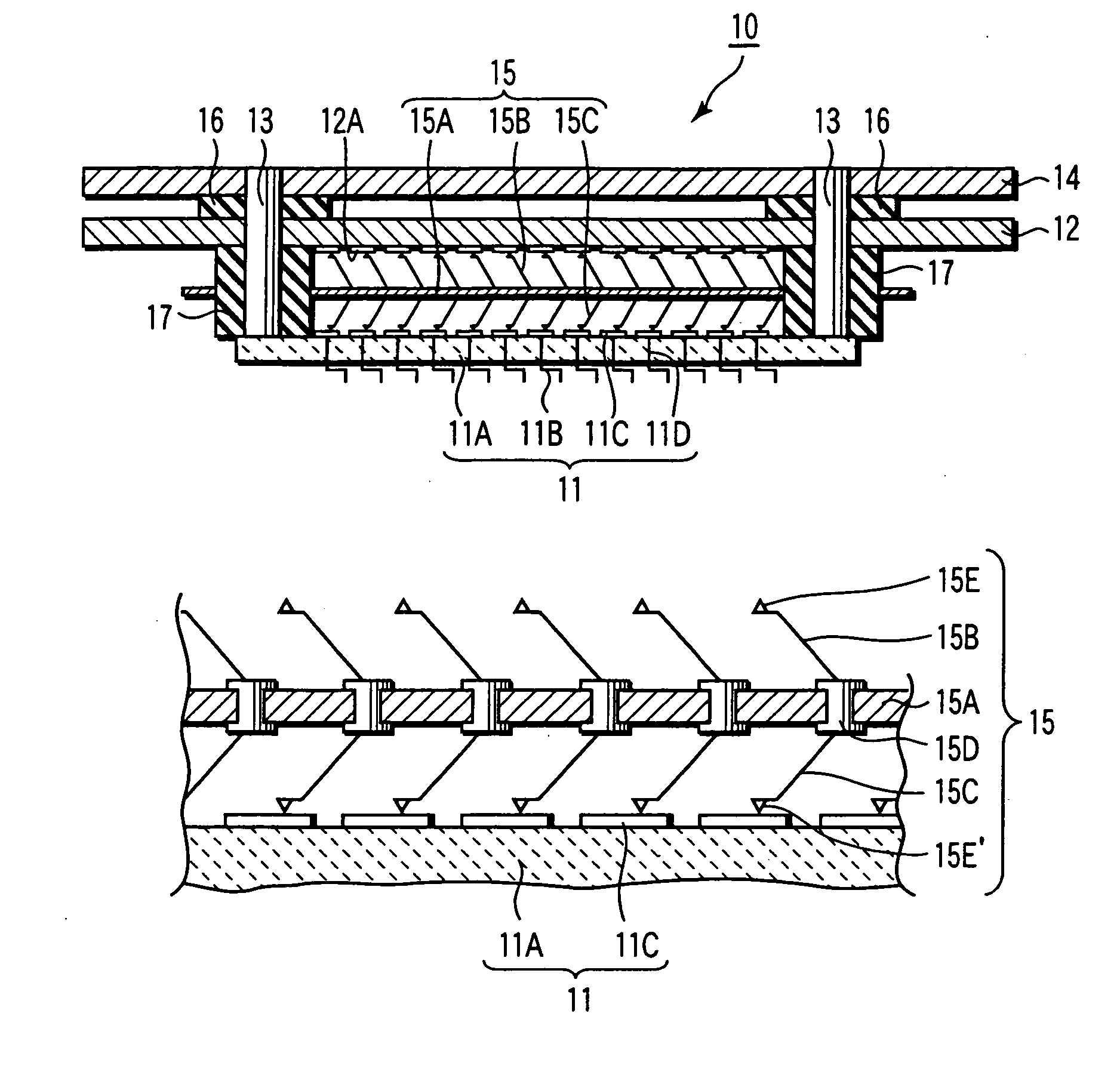

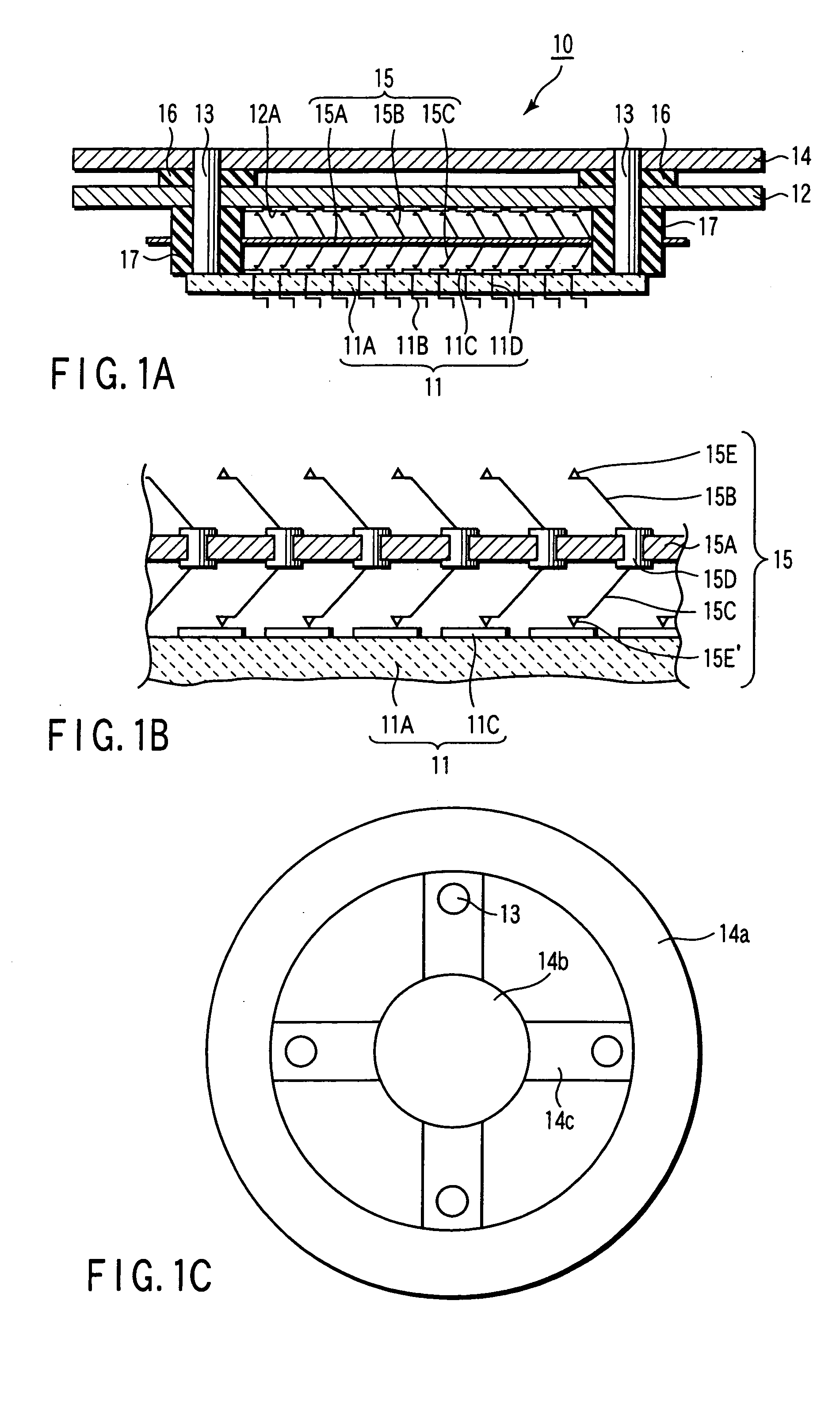

[0037] A probe card 10 according to the first embodiment shown in FIGS. 1A to 1C can have a contactor 11, intermediate member 15, circuit board 12, connecting member 13, and reinforcing member 14. The intermediate member 15 can also be referred to as an “interposer”. The circuit board (to be also referred to as a “printed wiring board” hereinafter) 12 is electrically connected to the contactor 11. The connecting member 13 connects the contactor 11 and printed wiring board 12 to integrate them. The reinforcing member 14 reinforces the printed wiring board 12 integrated by the connecting member 13.

[0038] As shown in FIGS. 1A and 1B, the contactor 11 can have a ceramic board 11A, a plurality of probes 11B, terminal electrodes 11C, and connecting wirings 11D. The ceramic board 11A is made of, e.g., a ceramic material. The probes 11B are formed on the lower surface of the ceramic board 11A. The terminal electrodes 11C are formed on the upper surface of the ceramic board 11A. The connect...

second embodiment

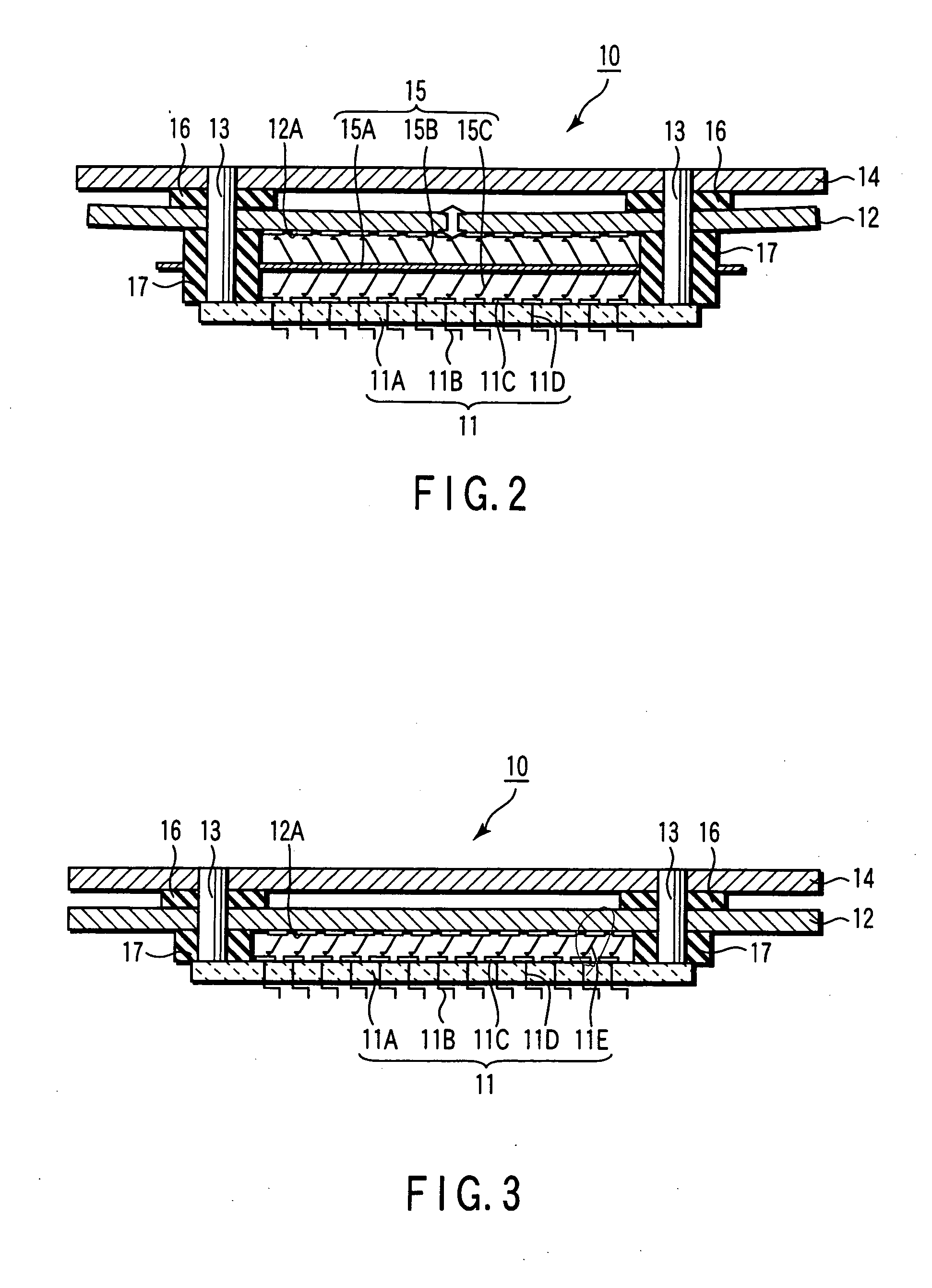

[0050] A probe card 10 of the second embodiment can have, as an intermediate member, a plurality of elastically deformable contacts 11E arranged on the upper surface of a contactor 11, as shown in, e.g., FIG. 3, in place of the intermediate member 15 shown in FIGS. 1 and 2.

[0051] The contacts 11E can be formed in the same manner as the contacts 15C of the interposer 15 shown in FIG. 1B. As shown in FIG. 3, the contacts 11E can be directly fixed to terminal electrodes 11C formed on the. upper surface of a ceramic board 11A of the contactor 11. The contactor 11 comes into electrical contact with terminal electrodes 12A of a printed wiring board 12 through the plurality of contacts 11E.

[0052] According to this embodiment, even when the printed wiring board 12 is deformed by thermal expansion, the thermal deformation can be absorbed by the contacts 11E of the contactor 11. This embodiment can provide the same operation and effect as those of the first embodiment. According to this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com