Highly textured non-woven composite wipe

a non-woven, wipe technology, applied in carpet cleaners, packaging goods, foodstuffs, etc., can solve the problems of low cost and affect another parameter, and achieve the effect of increasing flexibility, increasing thickness, and low bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

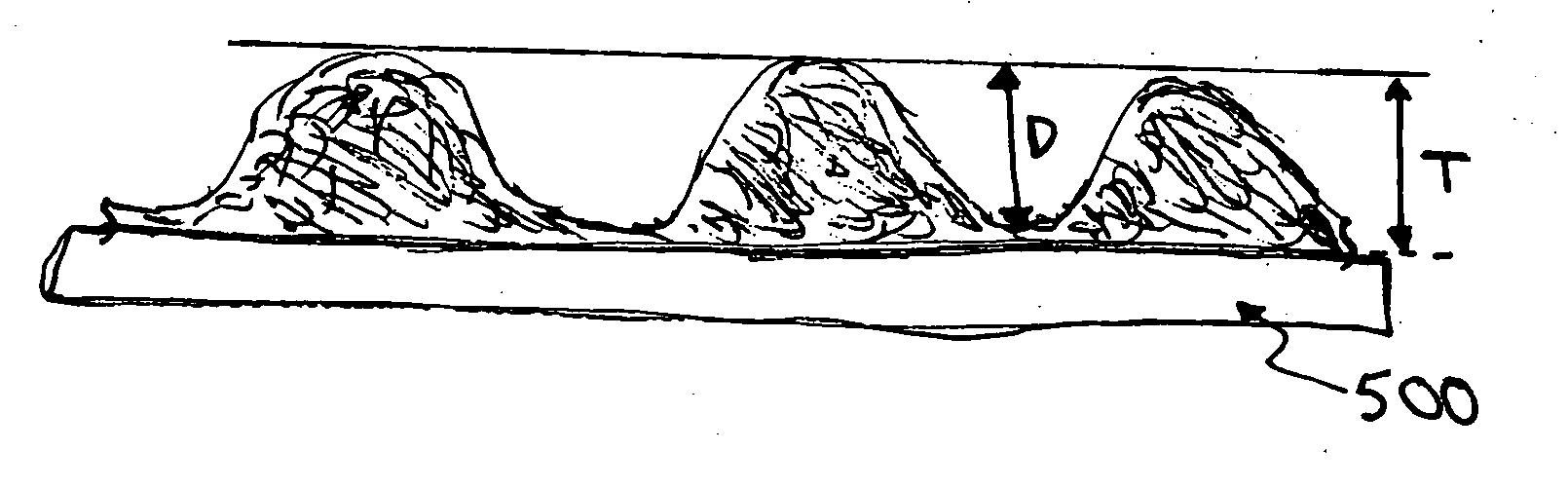

[0087] Wipes were made as described in the present application. Each wipe contained a three-layer laminate composite elastic material, which included two gatherable outside textured-surface coform layers and in inner elastomeric core layer.

Elastomeric Core

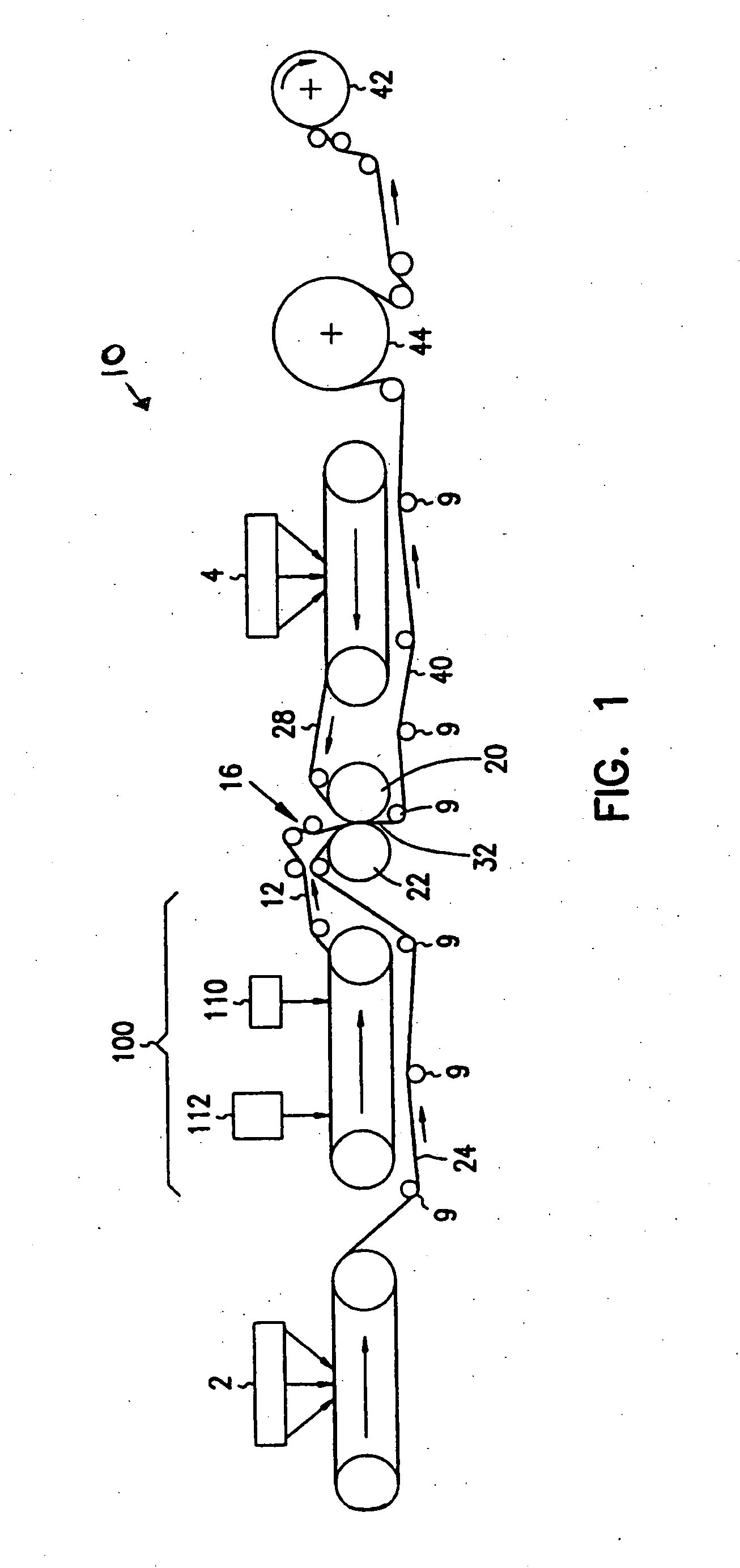

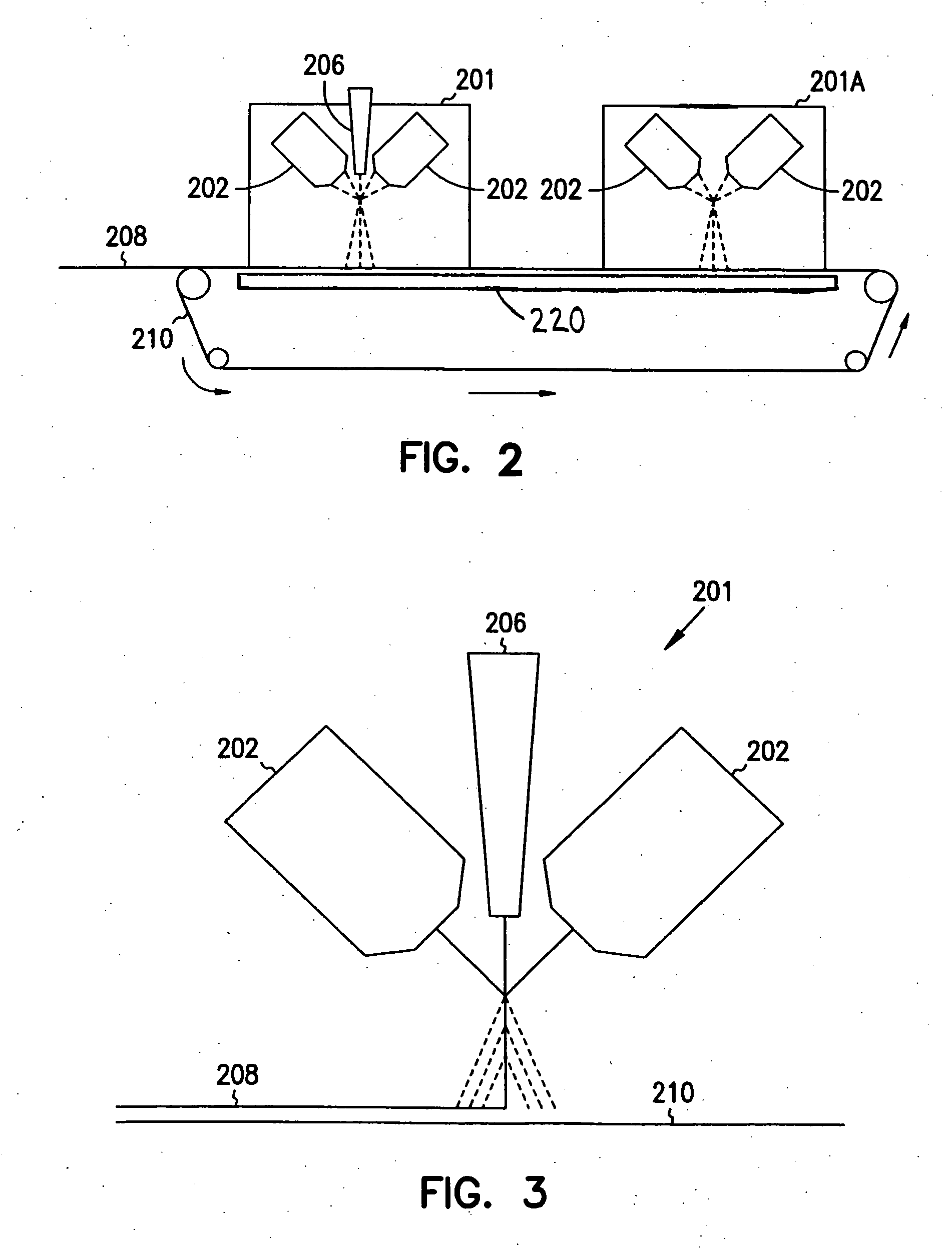

[0088] The elastomeric layer in this example is produced using a two bank meltblown process and a single continuous speed foraminous belt. The first bank of the meltblown process was setup to extrude elastomeric filaments / fibers directly onto the foraminous belt in a substantially parallel configuration without the use of heated primary air to draw the filaments. A metallocene-catalyzed polyethylene resin available from DOW Chemical Company, under the trade designation of Dow Affinity® XUS59400.03L, was used to produce the filaments at a nominal melt temperature of 220° C. The substantially parallel filaments were extruded through a spin beam with a nominal hole size of 0.07 cm and a density of 7 holes per cm. The velocity of th...

example 2

[0099] Following the procedure of Example 1, a composite elastic material is prepared using an elastomeric web containing 100% elastomeric meltblown fibers at a basis weight of 25 grams per square meter.

example 3

[0100] A particularly suitable solution and method of application for a washcloth wipe is described as follows:

[0101] The chemical applied to the substrate can be any useful chemical or mixture of various chemicals that enhances the functionality of the substrate for its intended purpose. Possible chemical additives include, without limitation, strength additives, absorbency additives, softener additives, surfactant additives, conditioning additives, aesthetic additives such as fragrances or dyes. Other additives include, without limitation, anti-acne additives, antimicrobial additives, antifungal additives, antiseptic additives, antioxidants, cosmetic astringents, drug astringents, deodorants, detergents, emollients, external analgesics, binders, film formers, skin moisturizing ingredients as known in the art, opacifiers, skin conditioning agents, skin exfoliating agents, skin protectants, sunscreens, vapor rubs and the like. Suitable chemicals are disclosed in U.S. Pat. No. 5,400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com