Autothermic packaging

a technology of autothermicity and packaging, which is applied in the direction of exothermal chemical reaction heat production, heat production devices, containers, etc., can solve the problems of insufficient air tightness, relatively weak seam, and difficulty in forming tight resistance connections,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

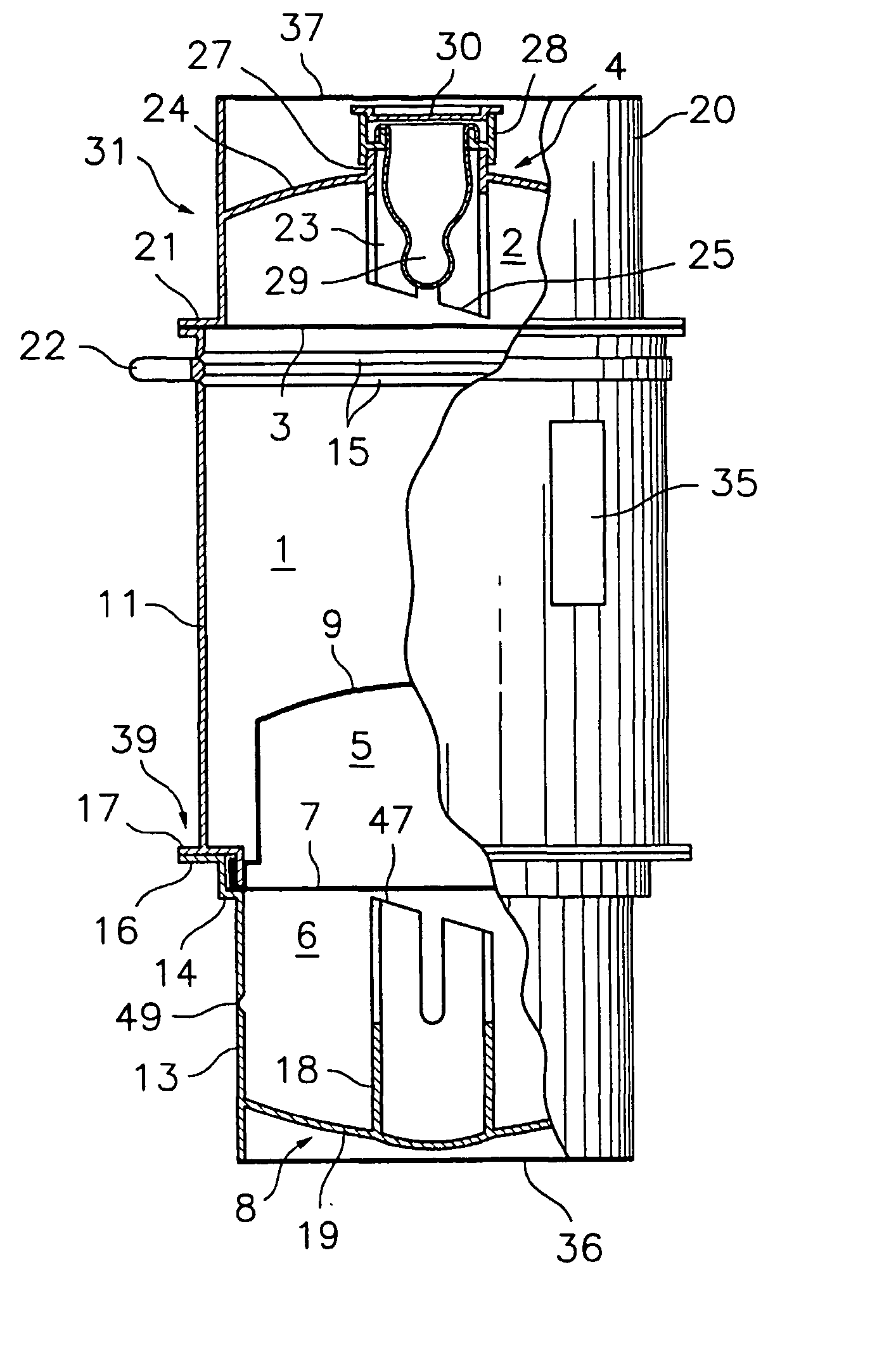

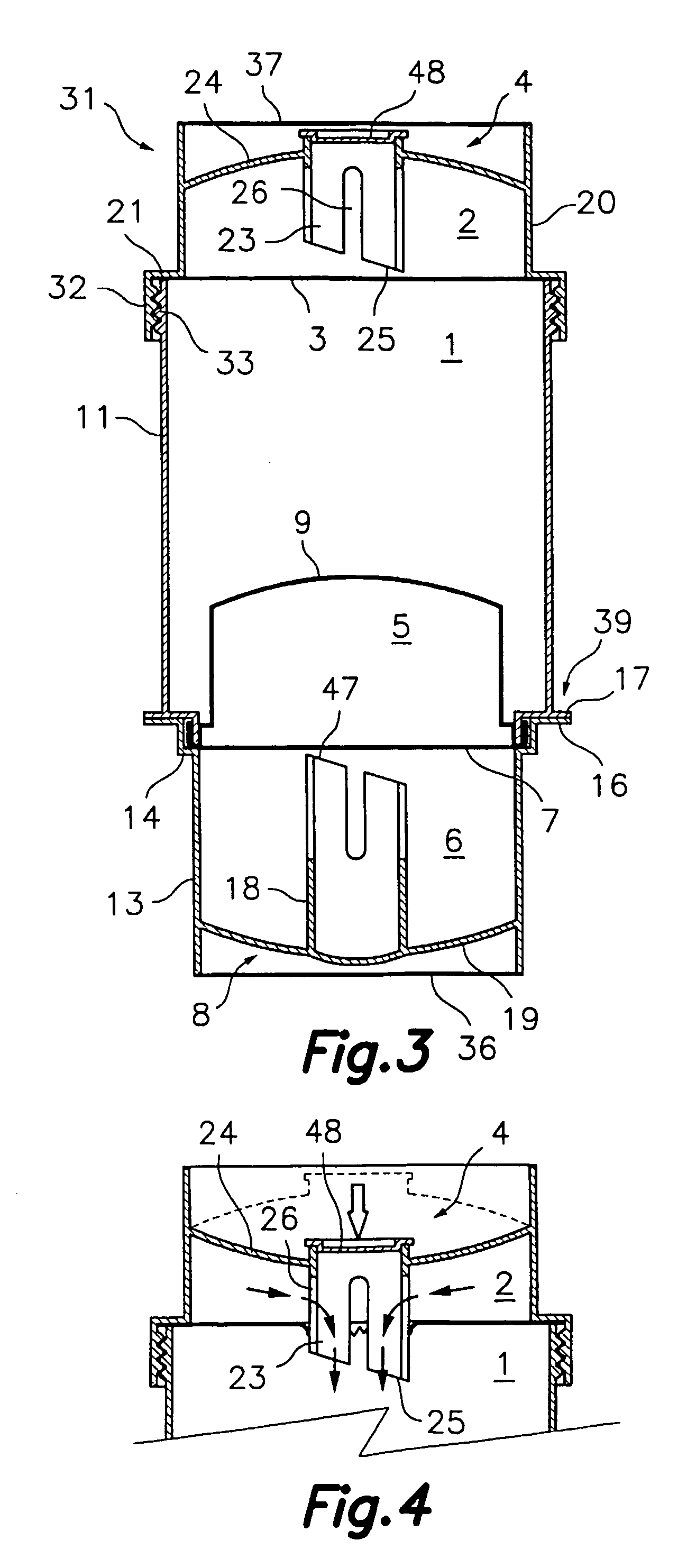

[0027] First of all, reference is made to FIG. 1 showing a basic embodiment of the autothermic packaging of this invention.

[0028] The autothermic packaging comprises a receptacle 1 for a food product, such as a drink or a meal in a liquid base. In the lower part of receptacle 1 there is a first compartment 5 containing a first substance that can react with a second substance contained in a second compartment 6, or undergo a phase change when exposed to conditions present in said second compartment 6, as explained below. The said first and second compartments 5, 6 back onto one another at their openings and they are separated by a breakable sheet 7 (e.g. a sheet of plasticized aluminium) which can be broken from the outside by penetration means 8 to produce a mixture and subsequent chemical reaction between said first and second substances, including heat exchange. Receptacle 1 and first compartment 5 have a common heat conducting wall 9 to facilitate the heat exchange therebetween....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com