Cylindrical developer carrier and production method thereof

a technology of developer carrier and cylindrical cylinder, which is applied in the direction of applications, instruments, ways, etc., can solve the problems of uneven projection and recess, unsatisfactory image, and repeated use of projection and recesses,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

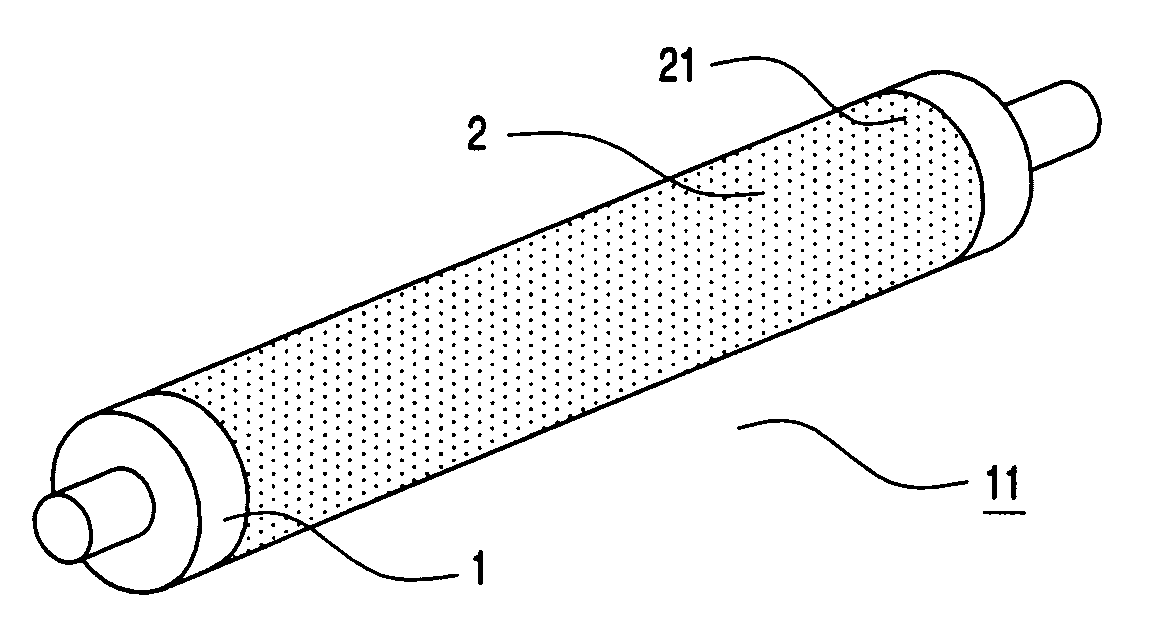

Image

Examples

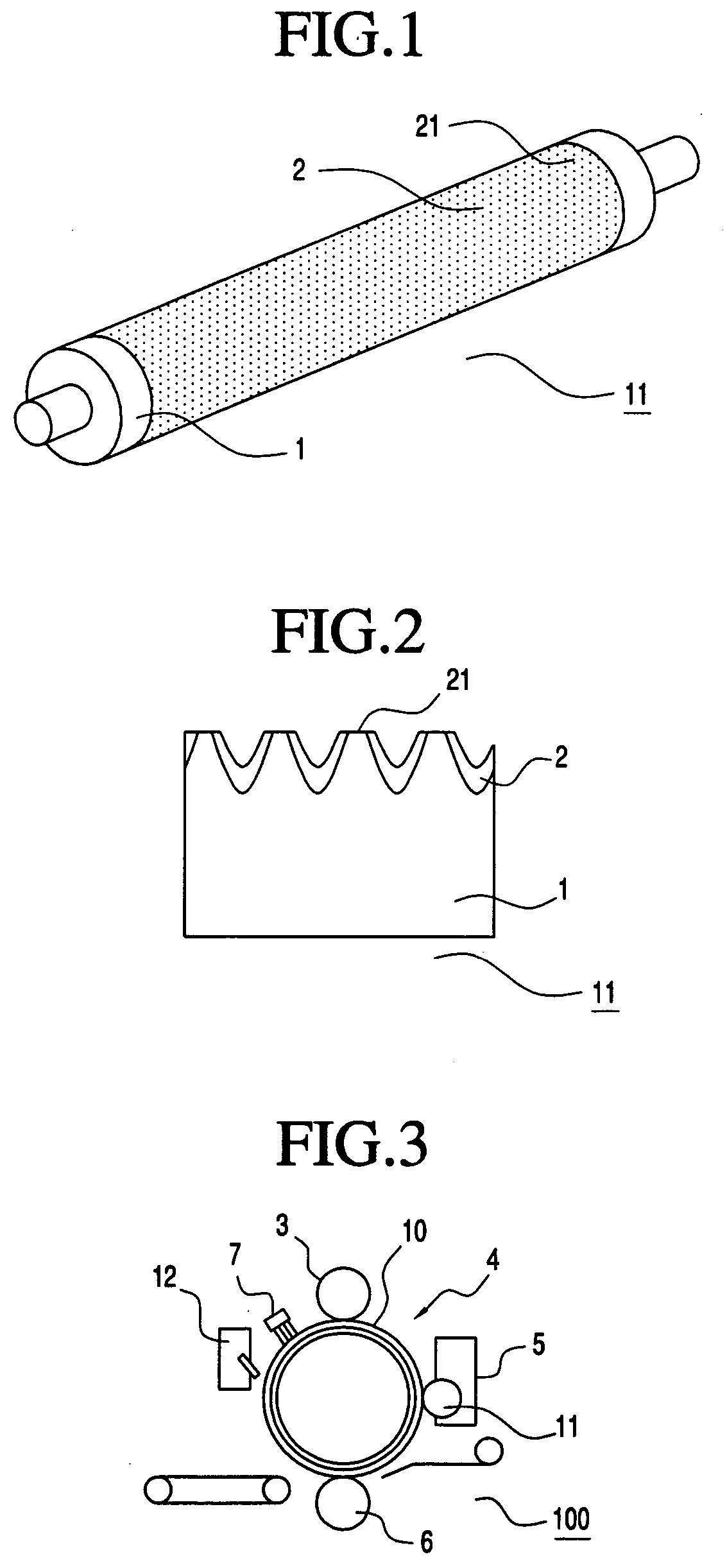

example

[0025] In order to accurately determine the relationship of quality of images to the ratio of the area of the minute holes formed immediately above the projections on the alumite layer 2 to the area shared by the formed alumite layer 2, the inventors conducted experiments. Initially, actual samples of the developing sleeve 11 were prepared, and were individually provided with ratios 5%, 10%, 20%, 40%, 50%, 60%, 70%, and 100% of the total area of the minute holes 21 to the actual area shared by the alumite layer 2 (hereinafter total ratios). The total area ratios were computed based on the difference in the light reflection ratios as between the alumite-layer formed portions and the minute holes 21. More particularly, a light-reflection rating instrument was used, with which the total area ratios of the minute holes 21 were computed based on a calibration curve prepared from a previously known sample. Alternatively, it is also allowable to compute area ratios by referring to an enlar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com