Continuous acidification demineralization process for producing osteoinductive bone; and osteoinductive bone produced thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

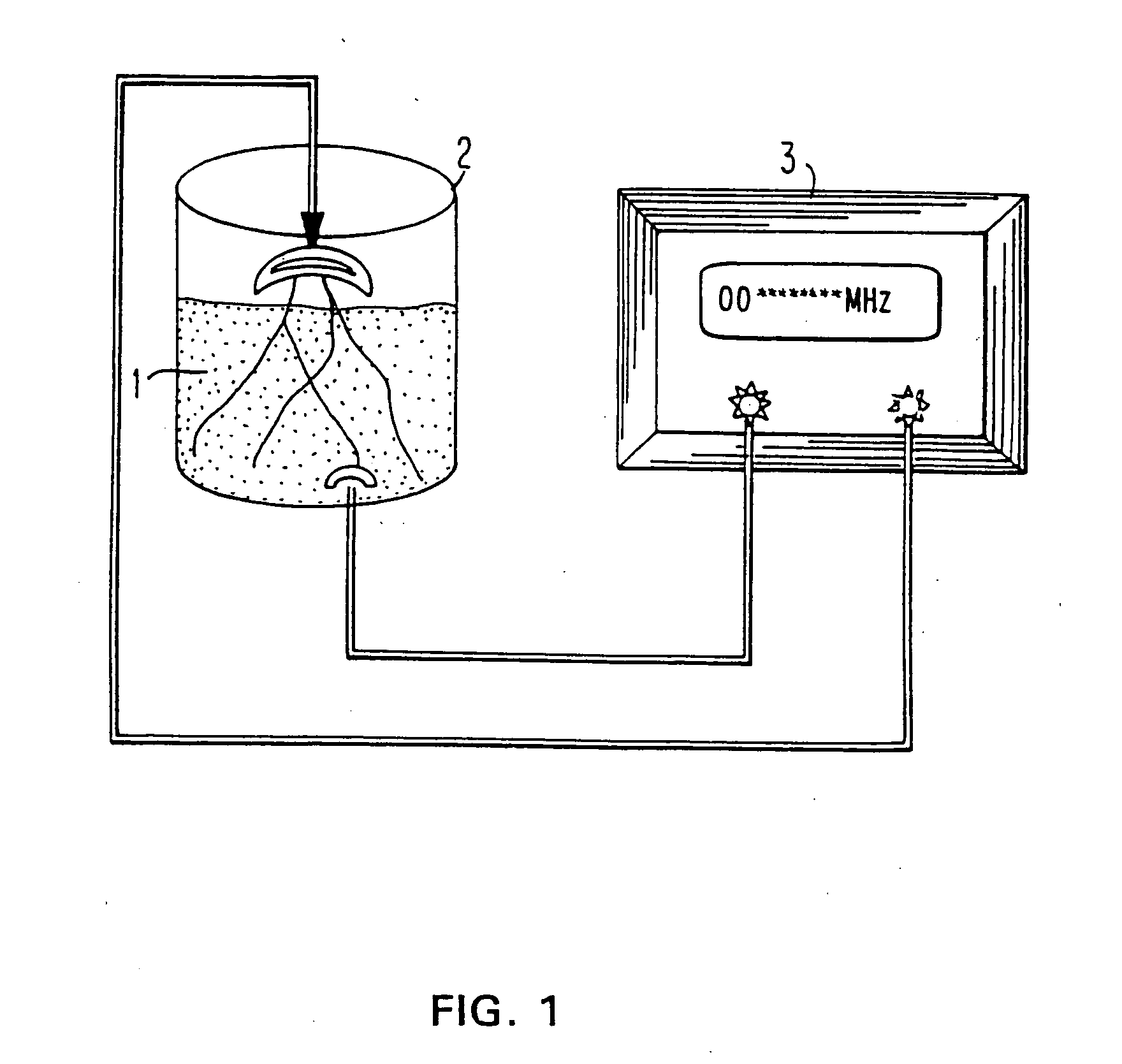

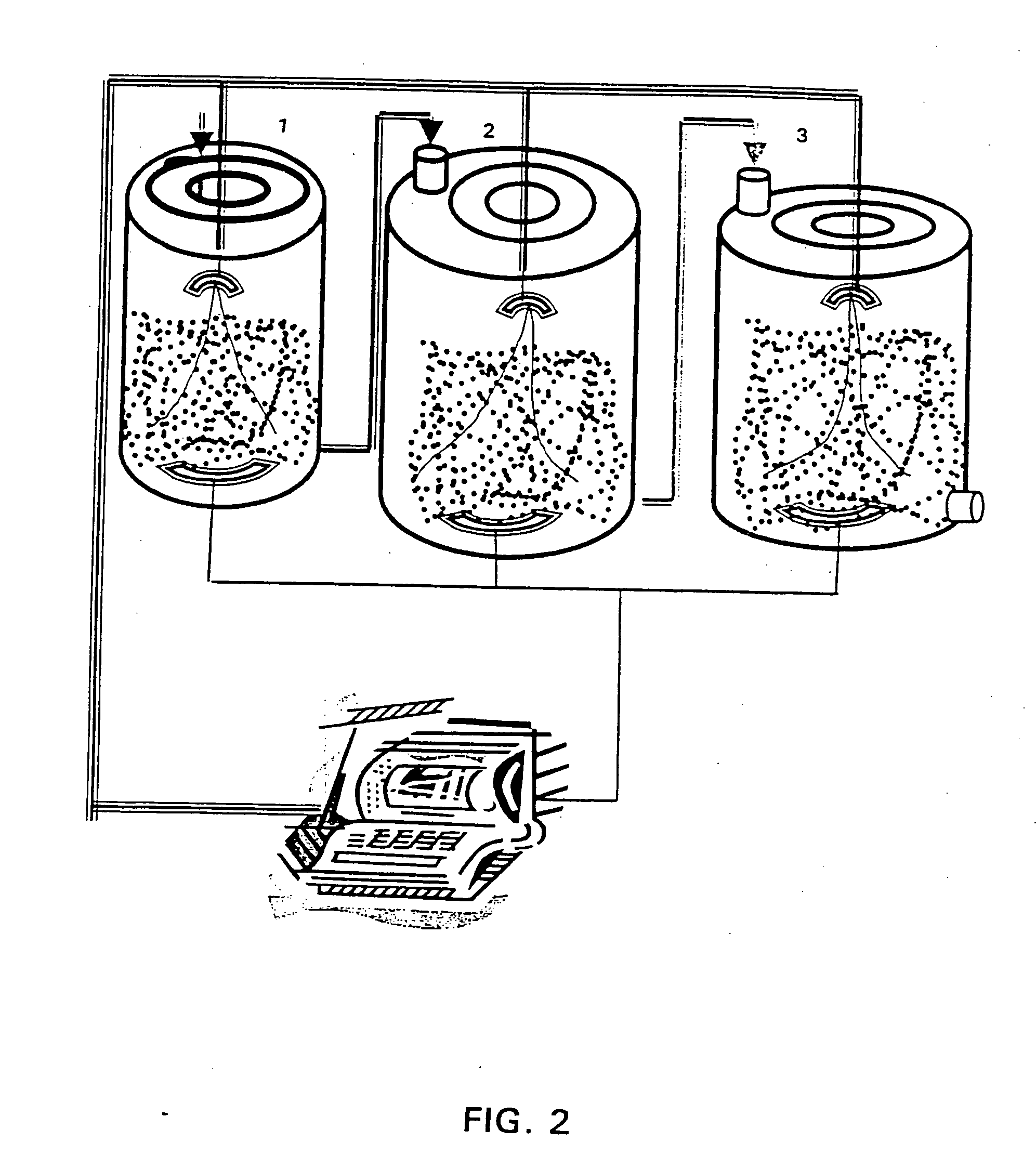

Method used

Image

Examples

Embodiment Construction

[0019] I. Definitions: The below definitions serve to provide a clear and consistent understanding of the specification and claims, including the scope to be given such terms.

[0020] Acid. By the term “acid” is intended any acid or acid solutions containing one or more acids, capable of demineralizing bone including for example, highly ionizable acids including but not limited to hydrochloric acid; and weakly ionizable acids including but not limited to citric acid. Such acid solutions may also include solutions of one or more acids in one or more alcohols, such alcohols including for example ethanol, and IPA, and solutions of one or more acids in glycerol or other organic and / or inorganic metal remover, i.e. metal chelator. Suitable acids include but are not limited to: formic acid, acetic acid, citric acid, propionic acid (organic acid), hydrochloric acid, phosphoric acid (inorganic acid); physiological tissue compatible hydroxy carboxylic acids including for example but not limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com