Method for manufacturing a golf club face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

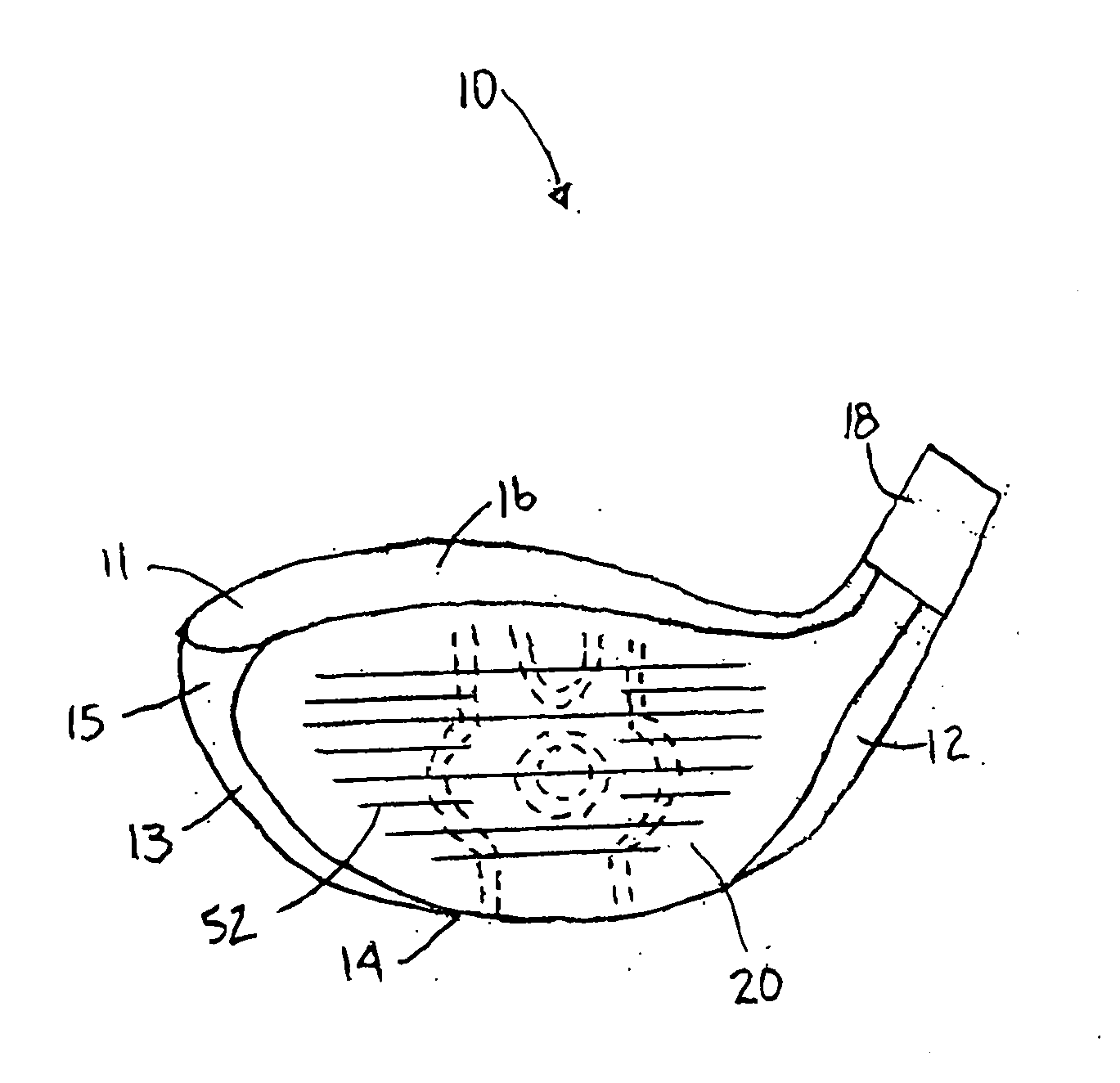

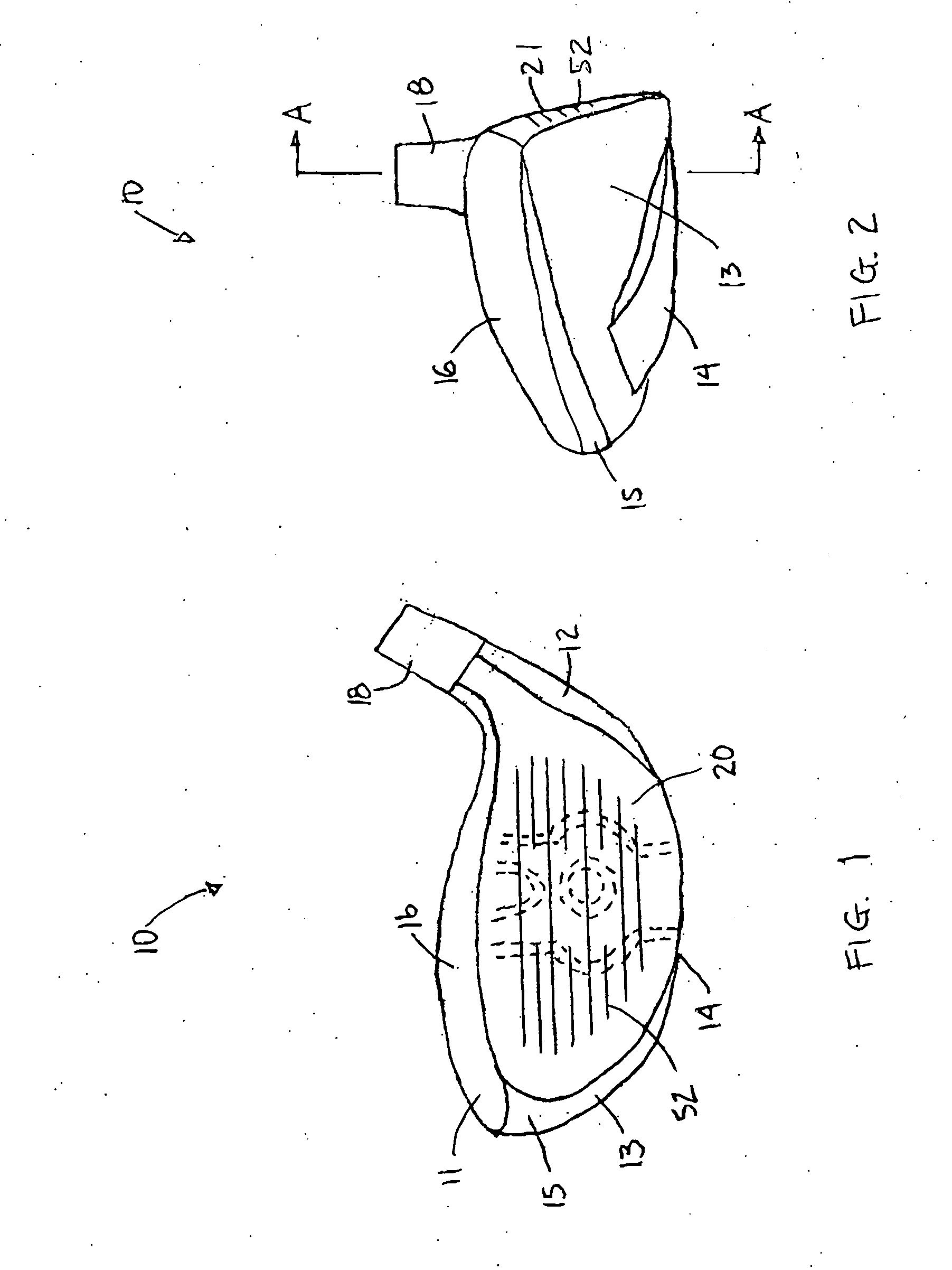

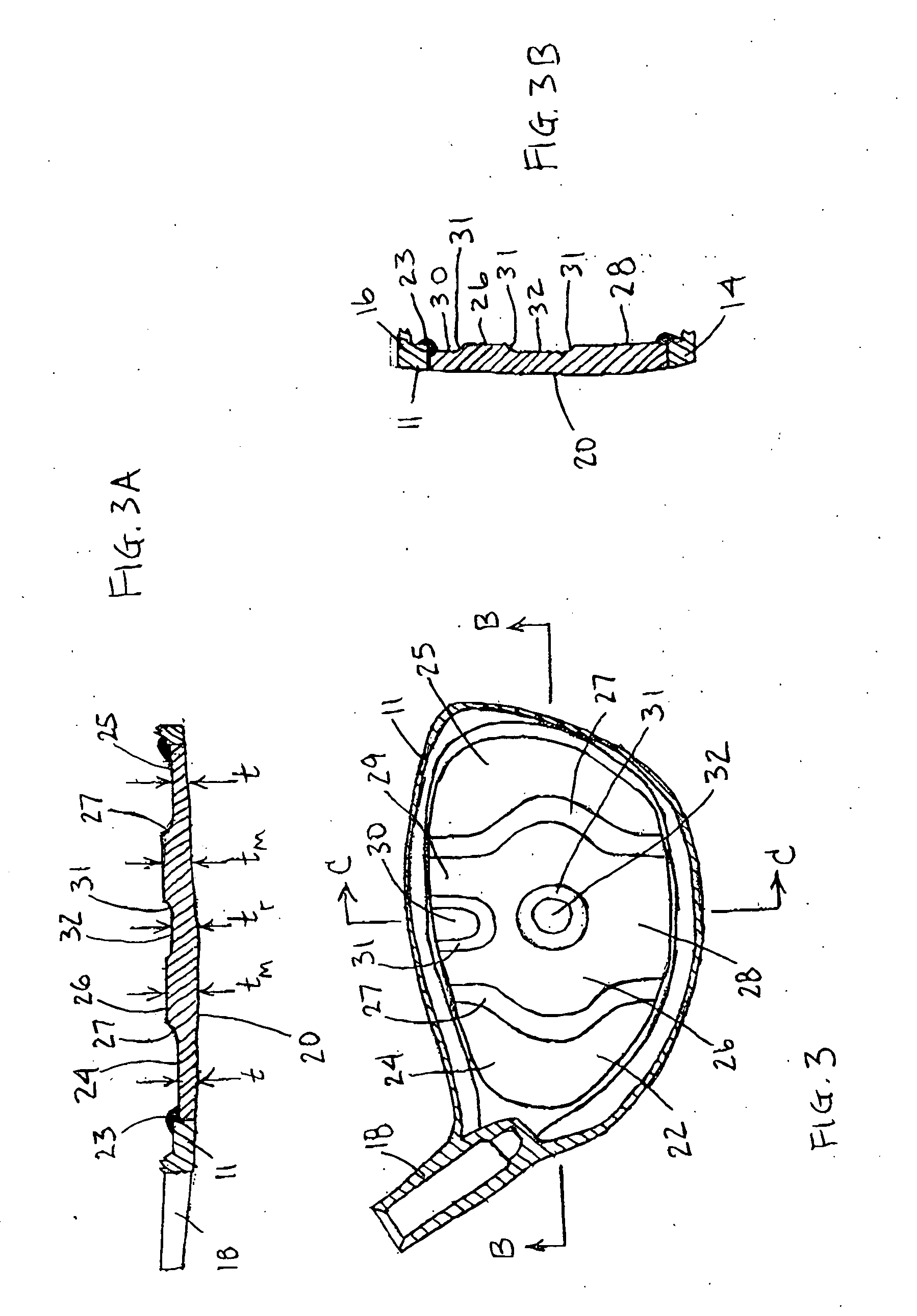

[0032] The drawings depict preferred embodiments of face plates achieved by methods of the present invention, the golf club face plates being for different types of golf club heads. With reference to FIG. 1, a club head 10 is shown that is similar to many metal wood club heads that are known in the art. Club heads within the scope of the invention are not necessarily limited to the shapes depicted. The club head 10 comprises a hollow metallic body 11 and a face plate 20. The body comprises a heel portion 12, a toe portion 13, a sole portion 14, skirt or side portion 15 and a crown portion 16 that cooperate to define a periphery 17 for an opening (see FIG. 3) for the face plate. The club head is normally connected to a shaft (not shown) by a hosel 18 that is integrally formed with the body.

[0033] Preferably, the body and / or face plate is constructed of steel, titanium or alloys thereof, but alternatively the body may comprise a composite or metal matrix material. The face plate may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com