Continuous production of carbon nanotubes and fullerenes

a carbon nanotube and fullerene technology, applied in the direction of carbonsing rags, chemical/physical/physicochemical processes, fullerenes, etc., can solve the problems of limited productivity, nanotube production by arc discharge technology, fullerene production, etc., and achieve the effect of preventing the melting of catalyst materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

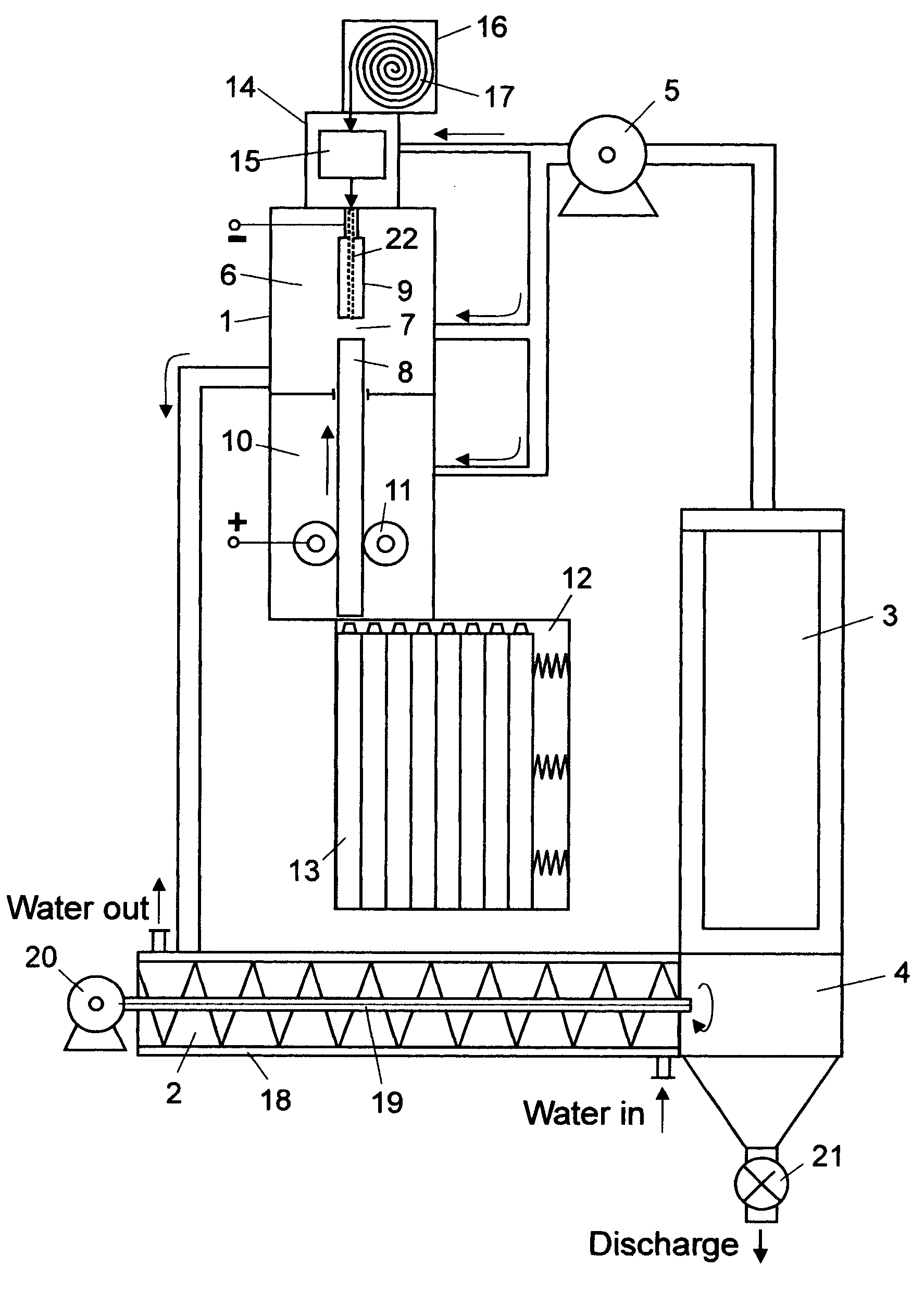

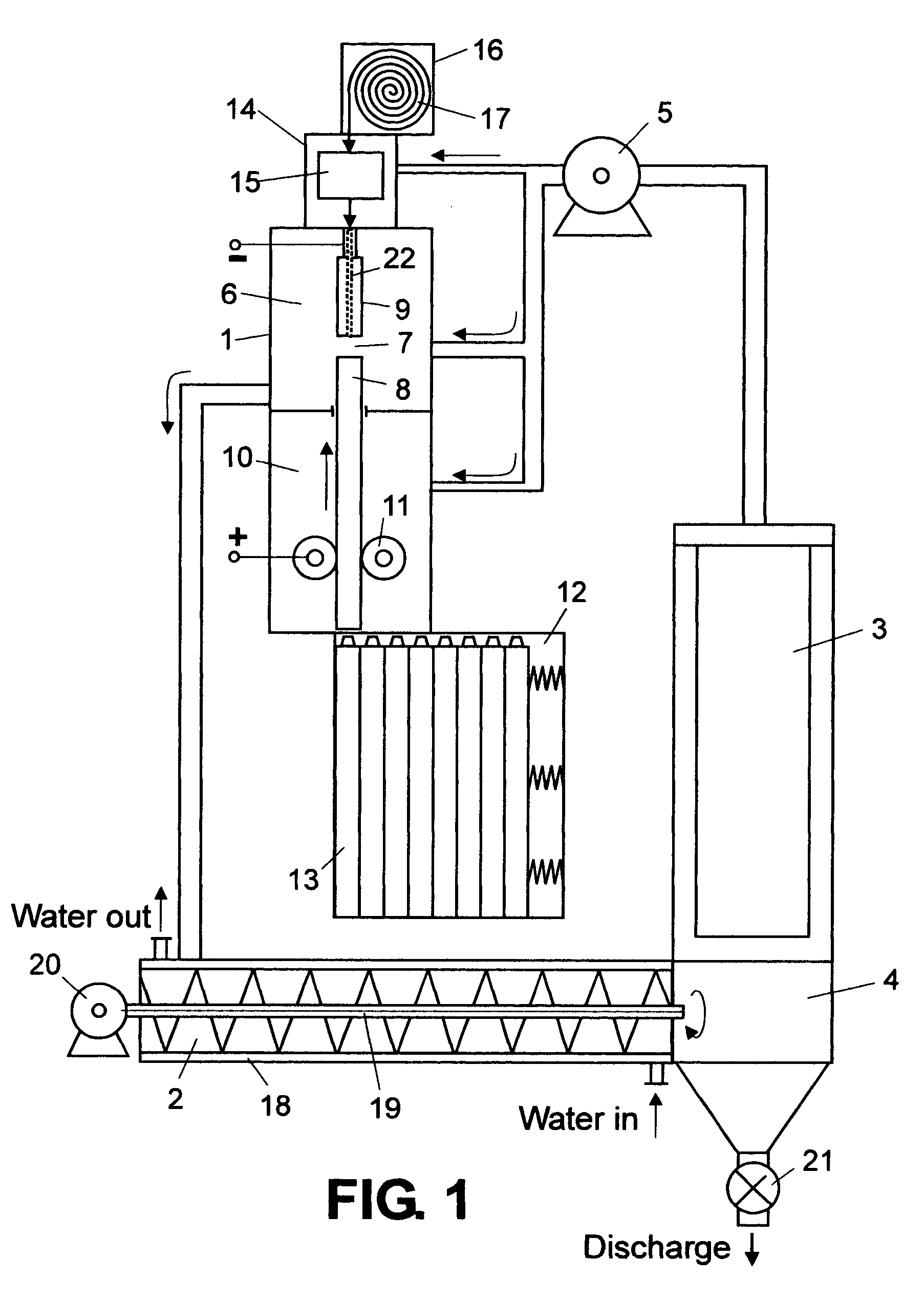

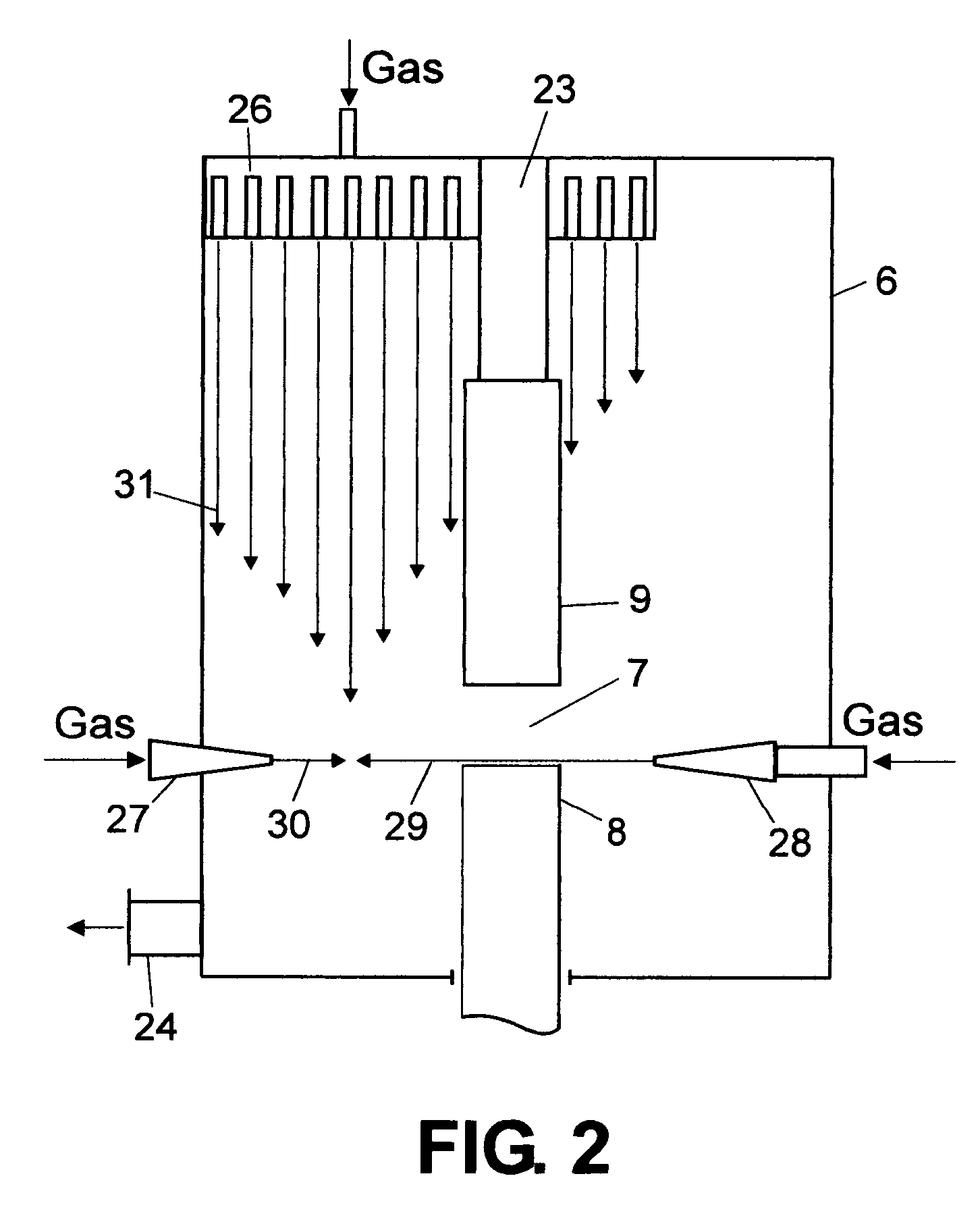

[0016] A method and a device for continuous production of fullerene-related carbon nanotubes and fullerenes are disclosed. FIG. 1 represents a closed-loop device, which constitutes an airtight water-cooled chamber 1, heat exchanger 2, filter 3, storage bin 4 with automatic discharge valve 21 and re-circulation pump 5. Chamber 1 comprises three interconnected sections —an arc discharge section 6 with vapor generation zone 7 situated between anode 8 and cathode 9 possessing perforation 22, anode feeding section 10 with anode feeding mechanism 11 and airtight plug-in cartridge 12 containing multiple graphite electrodes 13 and catalyst feeding section 14 with catalyst feeding mechanism 15 and airtight plug-in cartridge 16 containing catalyst 17 in a form of a metal wire or a fine metal powder. Heat exchanger 2 comprises water-cooled jacket 18 and screw conveyor 19 with drive 20. Arc discharge section 6 shown in FIG. 2 comprises vapor generation zone 7 between anode 8 and cathode 9, cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com