Wrinkle resistant composition

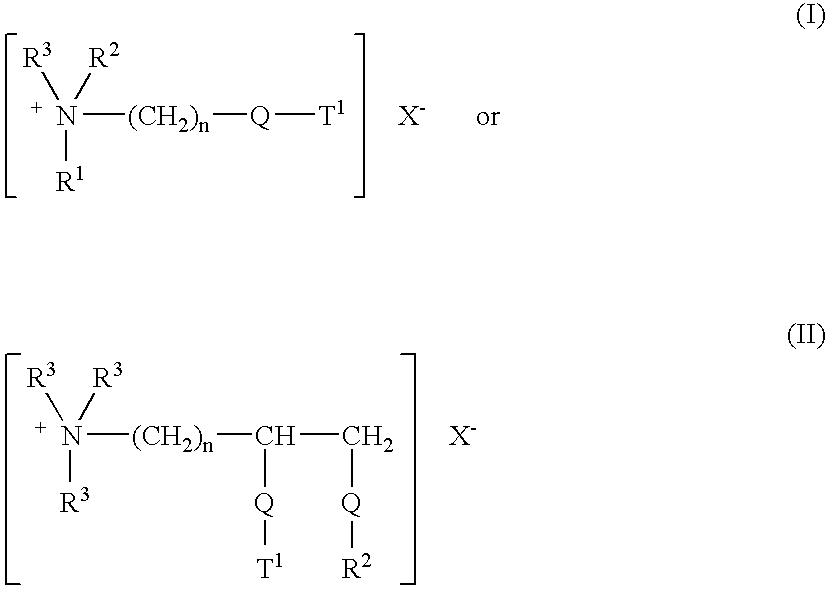

a composition and wrinkle-resistant technology, applied in the field of wrinkle-resistant compositions, can solve the problems of deterioration of the integrity and appearance of such fabrics and textiles, adversely affecting the appearance and integrity of the fabric and textile items so used and laundered, and affecting the use of fabric and textile items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

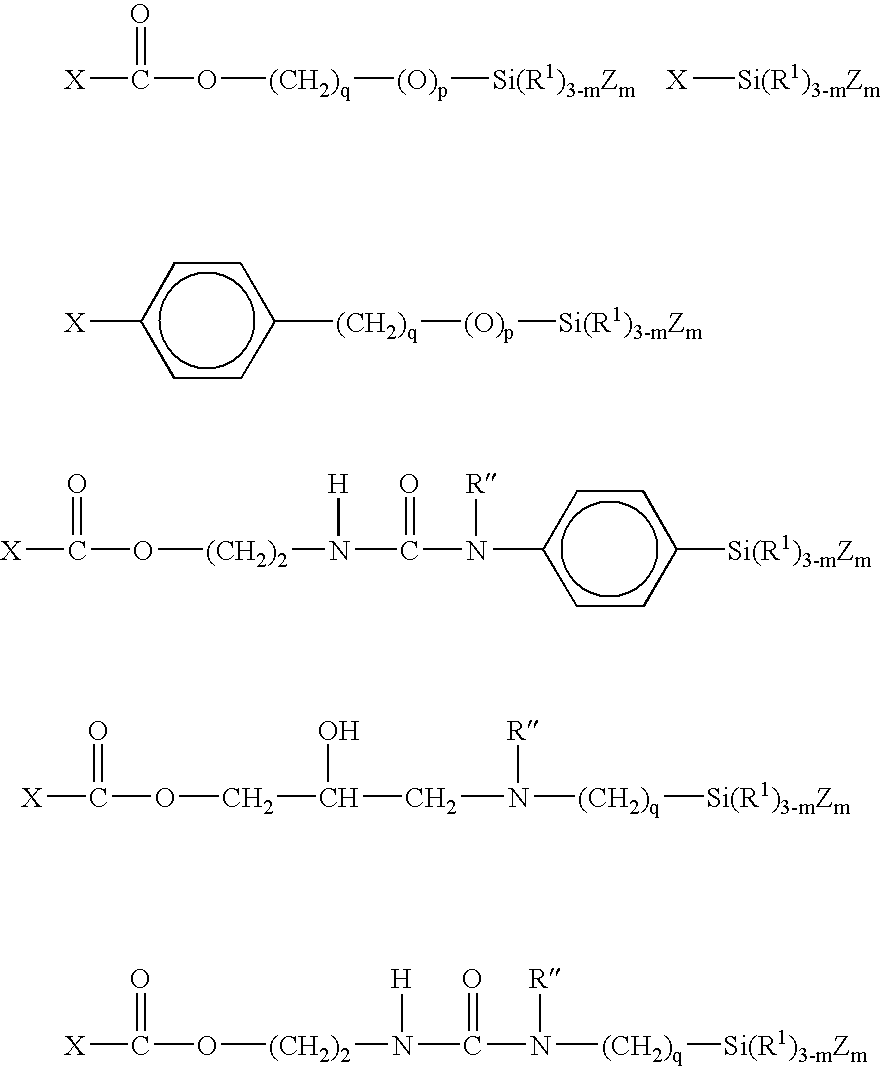

Embodiment Construction

1)-lubricant:

One essential component of the invention is a lubricant, preferably a water-soluble one. By means of this component, the composition provides an ease of ironing whilst still avoiding the staining of fabric and / or presenting safety hazard to the household members.

For the purposes of the present invention the term “water-soluble” is defined as “a component which when dissolved in water at a level of 0.2% by weight, or less, at 25° C., forms a clear, isotropic liquid”.

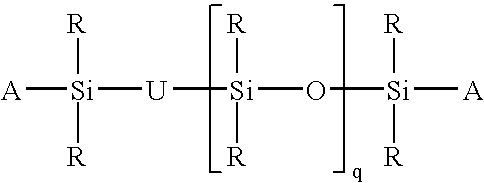

Typical water-soluble lubricants include components selected from nonionic silicone containing surfactants, sorbitan esters, ethoxylated sorbitan esters, and mixtures thereof. The water-soluble lubricants are preferably present in an amount of from 0.1% to 70% by weight of the composition, more preferably of from 1 to 10% % by weight of the composition for diluted composition and of from 20 to 50% by weight of the composition for concentrated compositions.

A preferred class of nonionic silicone contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wrinkle Recovery Angle | aaaaa | aaaaa |

| water-soluble | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com