Sputtering device

a technology of sputtering device and sputtering chamber, which is applied in the direction of electrolysis components, coatings, vacuum evaporation coatings, etc., can solve the problems of vacuum leakage, shorten maintenance hours, and increase production performance, so as to reduce the number of man-hours of fixing and shorten maintenance hours. , the effect of increasing the number o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

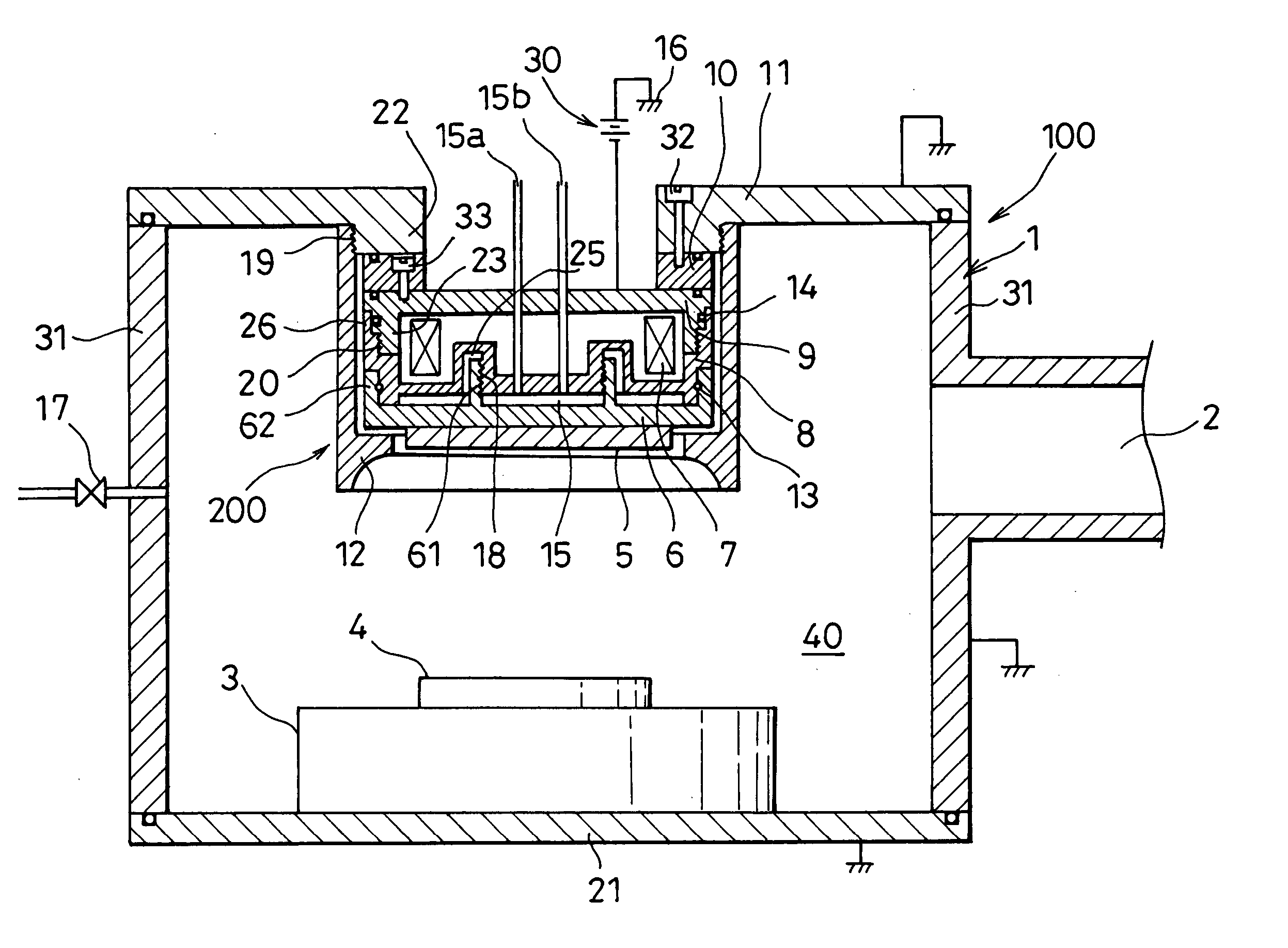

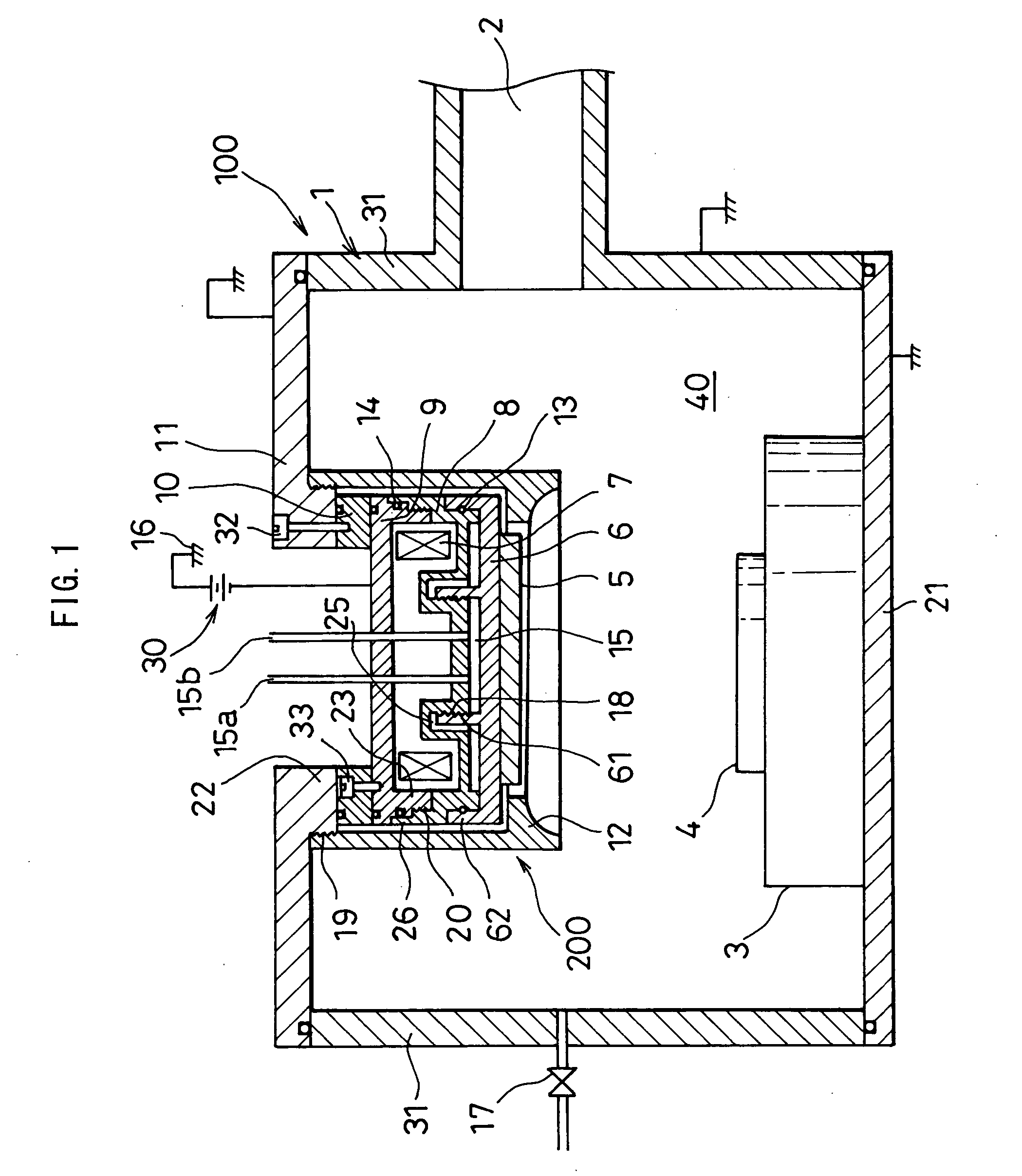

[0013] The following is explained about a working mode of the invention by referring a drawing.

[0014] In a sputtering device 100 according to the working mode of the invention, a vacuum container 1 is constituted of an upper cover 11, side wall portions 31 and a floor portion 21 and defines a vacuum chamber 40 in its inner side. An outlet for vacuum 2 is formed at anyone of the side wall portions 31 of the vacuum container 1, so that gas in the vacuum chamber 40 can be exhausted by a vacuum exhaust pump not shown in a figure. Furthermore, gas supply unit 17 is provided at anyone of the side wall portions 31 of the vacuum container 1, so that a desirable gas such as an argon gas can be introduced into the inner side of the vacuum chamber 40. Besides, the upper cover 11, the side wall portions 31 and the floor portion 21 of the vacuum container 1 are grounded respectively.

[0015] A substrate holder 3 is provided in the vacuum chamber 40 inside the vacuum container 1 and a substrate 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| vacuum | aaaaa | aaaaa |

| conductivity | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com