Fabric care compositions for lipophilic fluid systems

a technology of lipophilic fluid and fabric care composition, which is applied in the direction of textile dry cleaning apparatus, detergent compounding agent, washing receptacle, etc., can solve the problems of frequent ironing, significant portions of fabric articles used by consumers are not suitable for cleaning, and the conventional laundry process exposes fabric articles to dye transfer and shrinkage risk, etc., to achieve excellent fabric care properties and improve soil cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

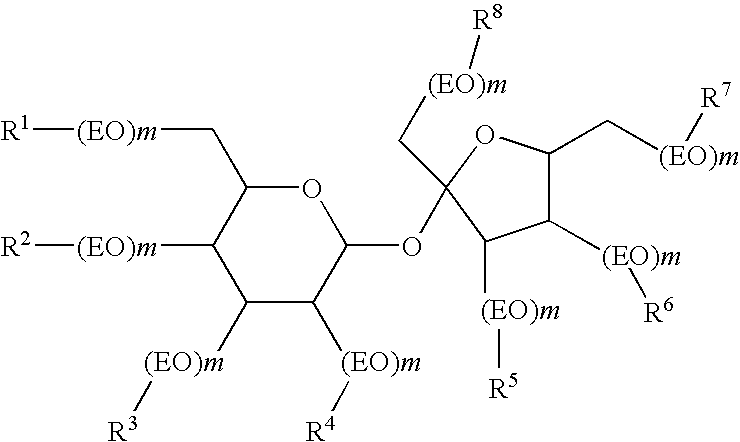

Image

Examples

example 1

Synthesis of Oleyl Based Sucrose Esters with an Average Degree of Esterification of 5.0:

Materials: oleyl (from soybean feedstock) sucrose ester=7.75 (MW=2390 g / mole) DMSO (Dimethylsulfoxide−EM Science)

Sucrose (342 g / mole−Domino Sugar)

Procedure:

Add the DMSO and sucrose into a 12 Liter reactor and mix well to dissolve the sucrose. Then add the oleyl ester 7.75 and 30 g catalyst. Heat to 100-110° C. React until desired degree of esterification is reached by measuring on SFC (supercritical fluid chromatography). Nitrogen is swept over the reactor.

When reaction is completed, cool to ˜65° C. then wash with 10% water and gently mix. Centrifuge at ˜6000 rpm for 5 minutes to remove remaining catalyst, soap and DMSO. Decant off the top liquid layer. Evaporate any remaining DMSO / Water by running material through the 2″ Wipe Film Evaporator (WFE) at 100° C. and ˜0.8 mm Hg.

example 2

A control fabric care composition containing a nonionic surfactant and one or more cleaning adjuncts is prepared by mixing the components as following:

ComponentsConcentration (wt %)Surfactant - Tergitol ® 15S-3*50Propylene glycol25TSF-4446**10Water15Total100

*a secondary alcohol nonionic surfactant from Dow

**a silicone copolyol from General Electric

This detergent composition is diluted with D5 / 0.5% water to 1 wt % concentration in the resulting wash liquor (referred to as “Example 2”). The stain removal or fabric cleaning capability of Example 2 is tested according to ASTM D4265-98 using cotton swatches and artificial stains.

example 3

A detergent composition is prepared according to Example 2, except that a sucrose ester (compound 1) was added at 15% of the formula partially replacing propylene glycol. This composition is diluted with D5 / 0.5% water to 1 wt % concentration in the resulting wash liquor. The stain removal or fabric cleaning capability of the composition is tested according to ASTM D4265-98 using cotton swatches and artificial stains. Example 3 shows improved stain removal on grass, US clay and spaghetti sauce compared to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com