Method and a system for converting liquid products into free-flowing powders with pre-cooling

a technology of liquid products and free-flowing powders, which is applied in the field of method and system for converting liquid products into free-flowing powders with precooling, can solve the problems of unfulfilled process demand, high viscosity of whey paste from the evaporator, and difficult handling and disintegration in the spin flash dryer,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0053] The feed material for the experiment was pre-treated rennet cheese whey with 6,00% total solids and permeate from the production of milk protein by ultrafiltration of sweet whey with 5,50% total solids.

[0054] In all Experiments whey or permeate was pre-concentrated in a multistage MVR falling film evaporator with 50 mm tubes of 18 m length as described by e.g. Knipschildt in Modern Dairy Technology (Ed. Robinson) 1986, Vol 1, p. 147 ff.

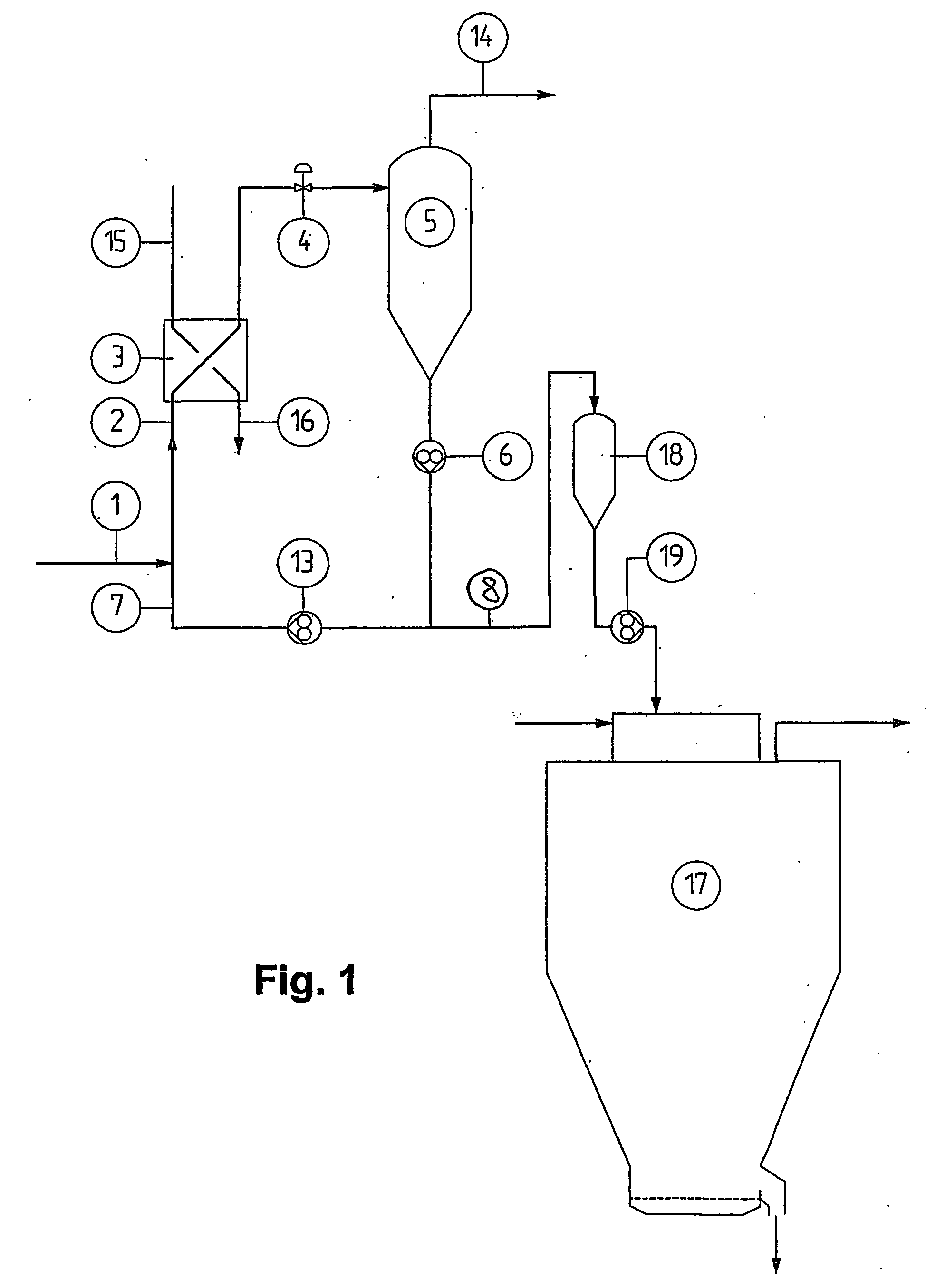

[0055] The experiments were performed according to the invention in a system as the one illustrated in the drawings. The concentrate from the falling film evaporator (not shown in the drawings) was fed to the recirculation line of a suppressed boiling forced circulation plate evaporator. After heating the separation process took place in a flash separator (a Single effect Paraflash, manufactured by APV Separation Processes). The concentrate from the exit line was then led to the cooler and subsequently fed directly to a spray dryer.

1 Feed kg / h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com