Aqueous one step type lubricanting agent for efficient cold forging

a technology of lubricant and cold forging, applied in the field of cold forging, can solve the problems of increasing the time and complexity of the process, no composition which has the same effect as the conventional process, and industrial waste containing phosphate compounds has been considered a serious problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

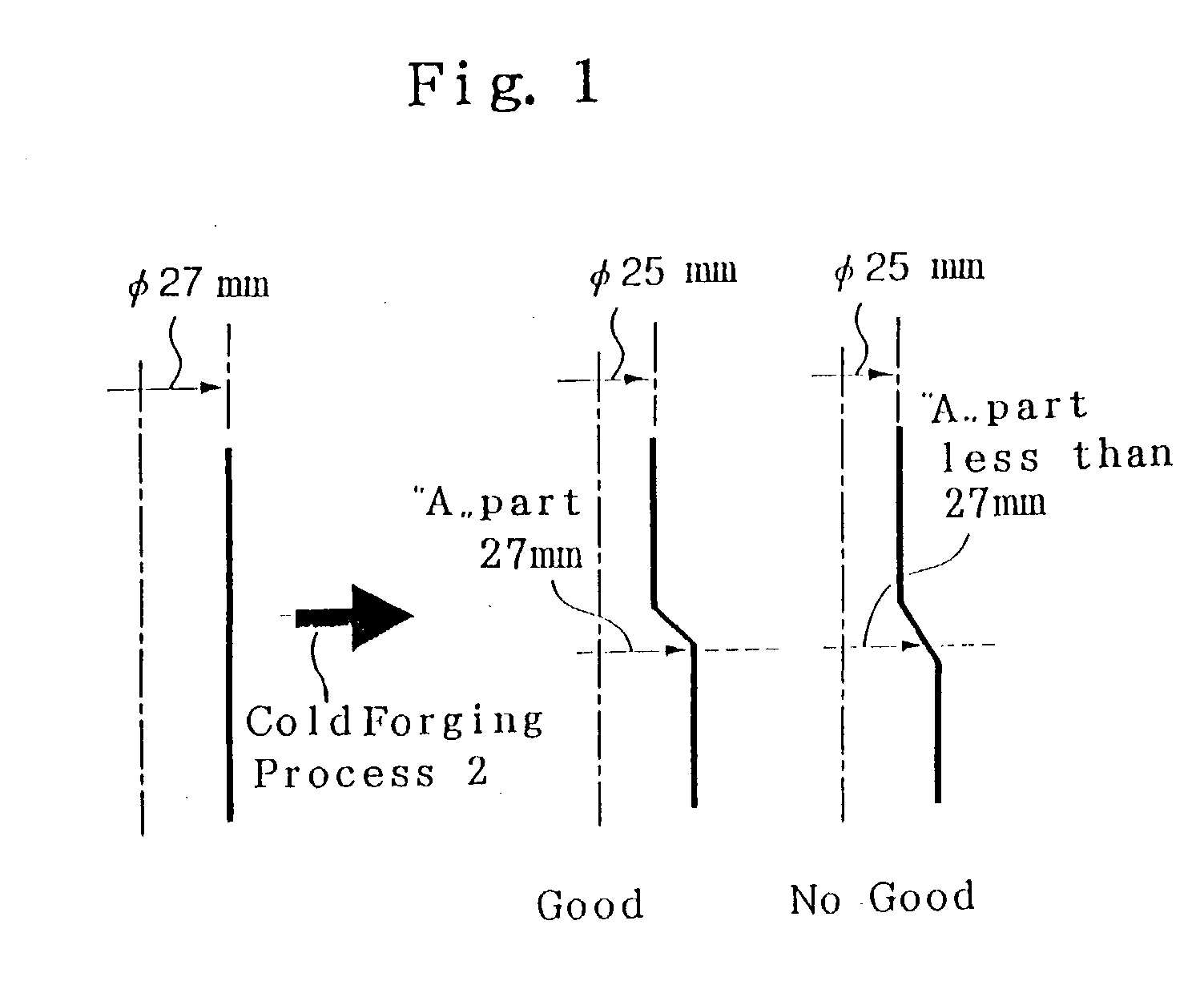

Method used

Image

Examples

embodiment example 1

[0081] A lubricant 1 as below was used, and coating was carried out according to lubrication process A (one process type). Lubricant 1:

[0082] Aqueous inorganic salt: Sodium tetraborate

[0083] Wax: Polyethylene wax(1% by weight of nonionic surface active agent was added for improving dispersion).

[0084] Metal salt of fatty acid: Calcium stearate

[0085] Solid component ratio: (B) / (A): 0.70

[0086] Solid component ratio (C) / (A): 0.1

[0087] Weight of formed coating layer, g / cm.sup.2: 15

embodiment example 2

[0088] A lubricant 2 as below was used, and coating was carried out according to lubrication process A (one process type). Lubricant 2:

[0089] Aqueous inorganic salt: Potassium tetraborate

[0090] Wax: Microcrystalline wax(1% by weight of nonionic surface active agent was added for improving dispersion).

[0091] Metal salt of fatty acid: Calcium stearate-Solid component ratio: (B) / (A): 0.6

[0092] Solid component ratio (C) / (A): 0.3

[0093] Weight of formed coating layer (g / cm.sup.2): 15

embodiment example 3

[0094] A lubricant 3 as below was used, and coating was carried out according to lubrication process A (one process type). Lubricant 3:

[0095] Aqueous inorganic salt: Sodium tetraborate

[0096] Wax: Polyethylene wax (1% by weight of nonionic surface active agent was added for improving dispersion).

[0097] Metal salt of fatty acid: Calcium stearate

[0098] Solid component ratio: (B) / (A): 0.6

[0099] Solid component ratio: (C) / (A): 0.2

[0100] Weight of formed coating layer (g / cm.sup.2) 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com