Transparent candle

a transparent candle and candle technology, applied in the field of transparent candles, can solve the problems of inconvenient storage, inconvenient storage, and inability to store candles,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

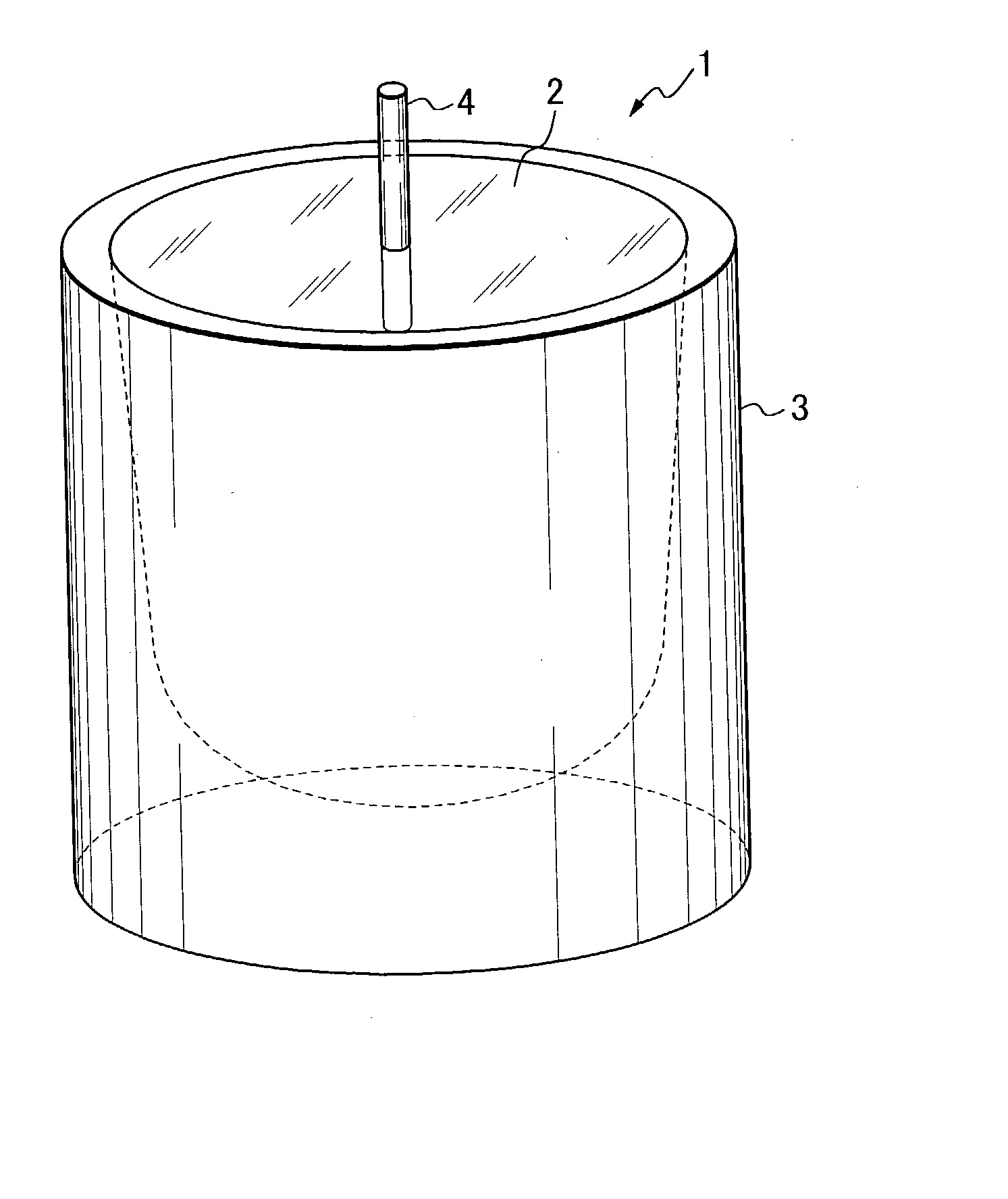

[0021] 50 to 90% by weight of plant fat and oil, 5 to 40% by weight of natural wax, and 1 to 10% by weight of hydrogenated castor oil or a fat and oil gelling agent, are mixed at amounts selected as appropriate in order to prepare a candle composition 2.

[0022] As plant fats and oils, fats and oils having relatively low melting points of 70.degree. C. or less, such as linseed oil, cotton seed oil, rapeseed oil, castor oil, sunflower oil, or camellia oil were used. As natural waxes to be used for the candle composition, beeswax, carnauba wax, candelilla wax, Japan wax (or sumac wax), Chinese wax (or insect wax), or others were used. As a fat and oil gelling agent, 12-hydroxystrearic acid was utilized.

[0023] The candle composition 2 thus prepared can be visually recognized to be in a transparent state as a whole.

[0024] On the other hand, a container 3 was formed of 100% by weight of natural wax, while another containers 3 were formed by mixing 50 to 99% by weight of natural wax with 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com