Sheet metal stud and composite construction panel and method

a technology of composite construction and metal studs, which is applied in the direction of building components, structural elements, applications, etc., can solve the problems of large heat loss through the panels, labor transportation and erection of such heavy panels, and relatively heavy thick materials of concrete panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

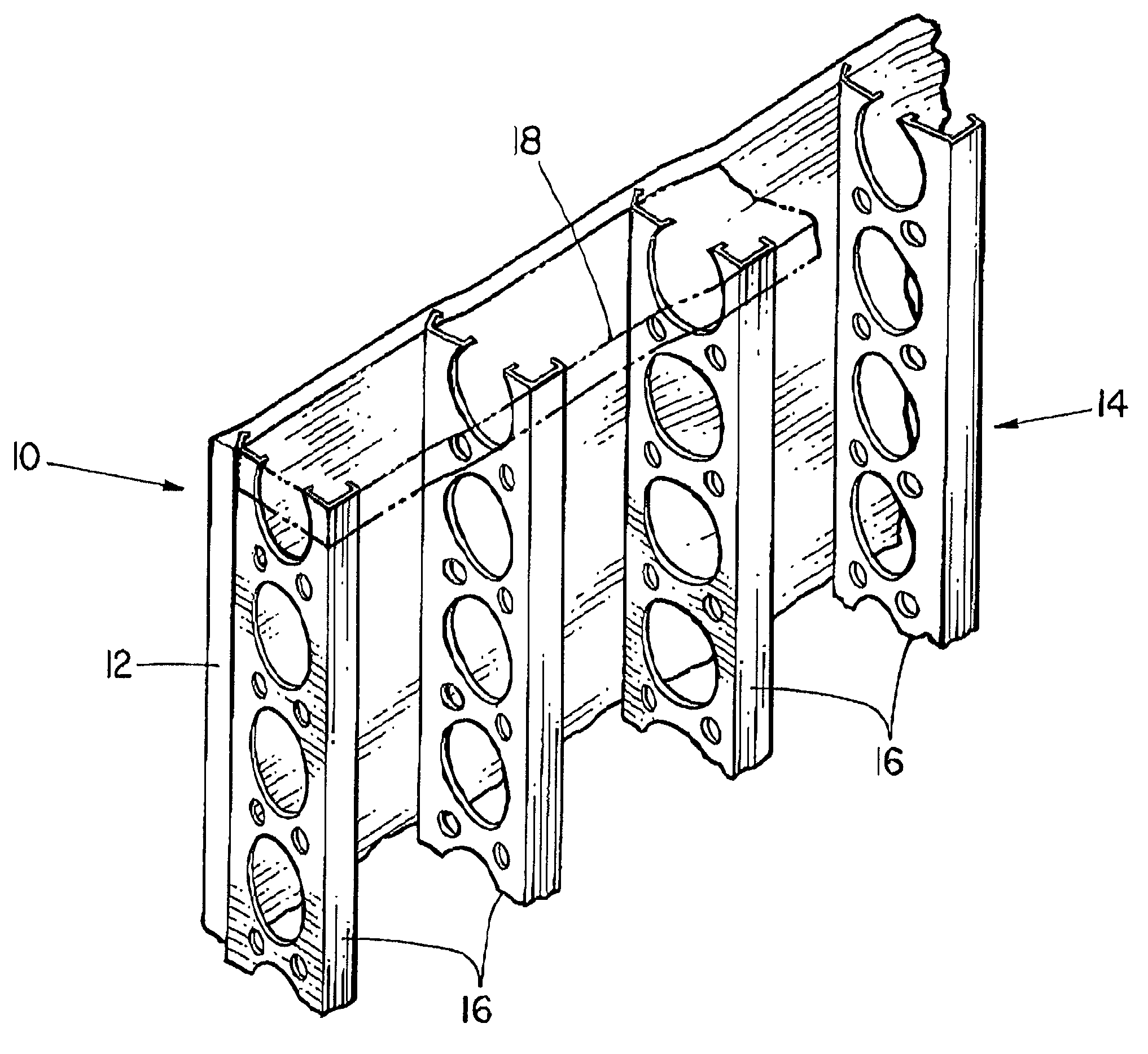

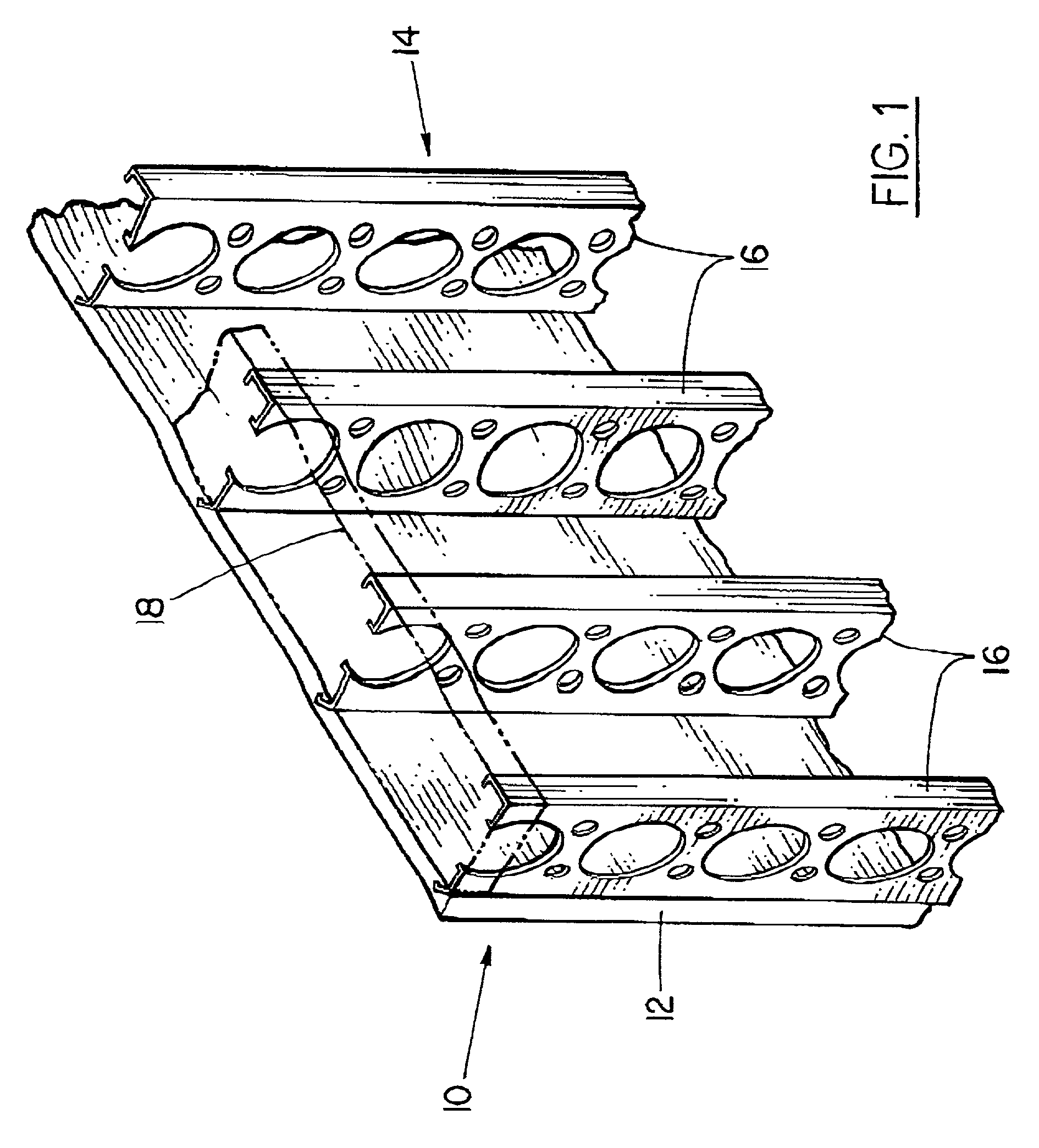

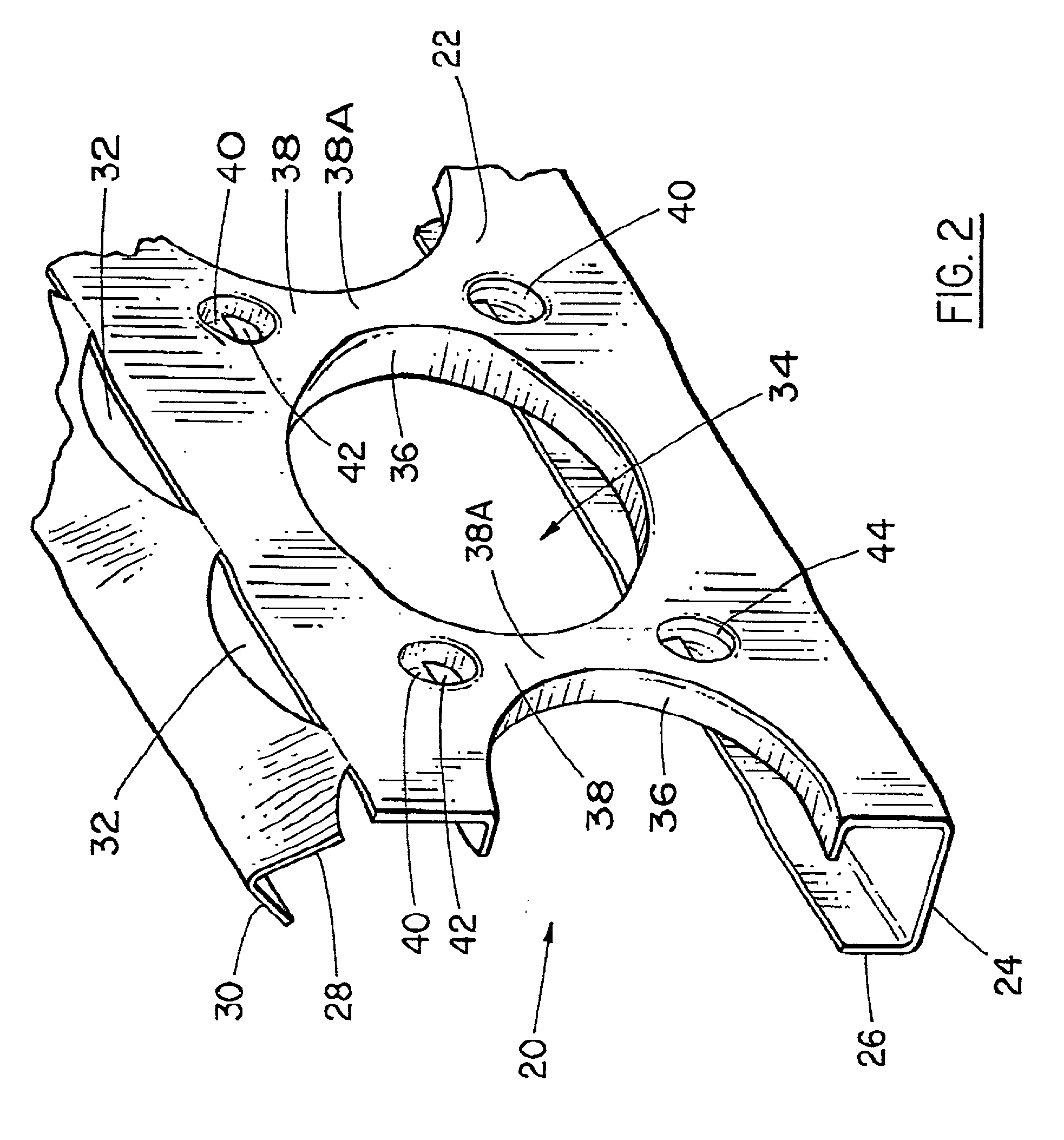

[0035] Referring first of all to FIG. 1 it will be understood that the invention relates generally to a composite wall panel 10 typically looking somewhat like the illustration of FIG. 1. Such a composite panel 10 has a thin panel 12 of cast material , and a reinforcing frame or grid indicated generally as 14, formed of sheet metal studs indicated generally as 16. Typically the cast material is concrete, but various special forms of concrete are available, which would be suitable for the purpose. However the invention is not limited to concrete materials as such, but includes other panel materials which are capable of being cast into a thin panel and allowed to cure. As will be explained below such studs have embedment portions which are embedded into the concrete 12.

[0036] Typically the studs 16 may be arranged on twenty-four inch centers , and may have top and bottom transverse studs 18 joining the top and bottom ends of the studs 16. The top and bottom studs will usually be plain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com