Enclosure member, and multi-link conveyor chain

a conveyor chain and locking member technology, applied in the direction of conveyors, transportation and packaging, railway components, etc., can solve the problems of multi-link conveyor chain collapse, pin head wear and eventually shear off, and elongated pin dislocation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

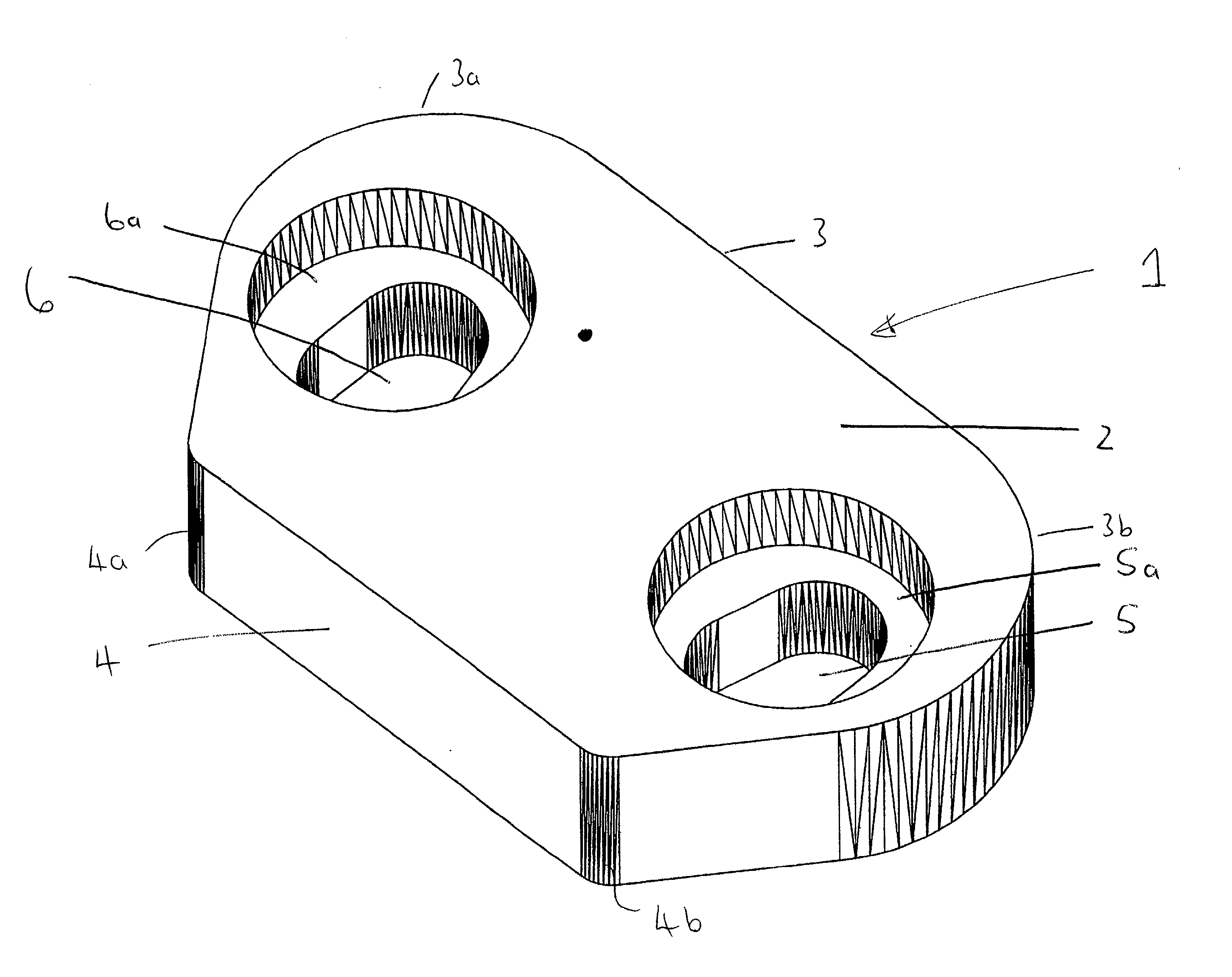

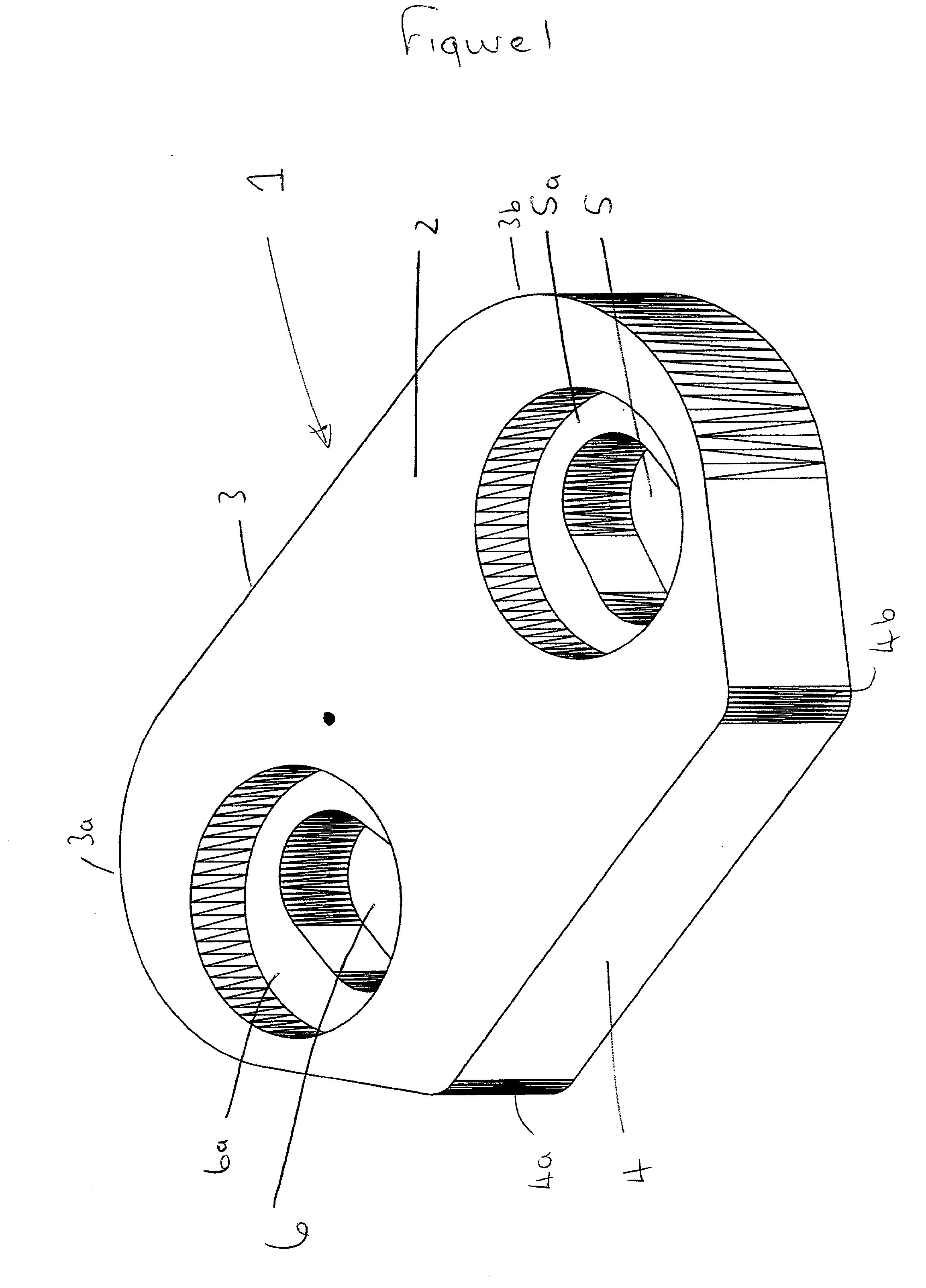

[0051] FIG. 1 illustrates an embodiment of the enclosure member of the invention designated generally by reference numeral 1. The enclosure member 1 comprises a trapezoidal main body 2 having a long side 3 parallel to a short side 4. The corners 3a and 3b of the long side 3 are rounded off (and to a lesser extent so are the corners 4a and 4b of the short side 4). The main body 2 defines a first non-circular aperture 5 and a second non-circular aperture 6, each of which are elliptical and provided with a cylindrical counterbore 5a and 6a respectively.

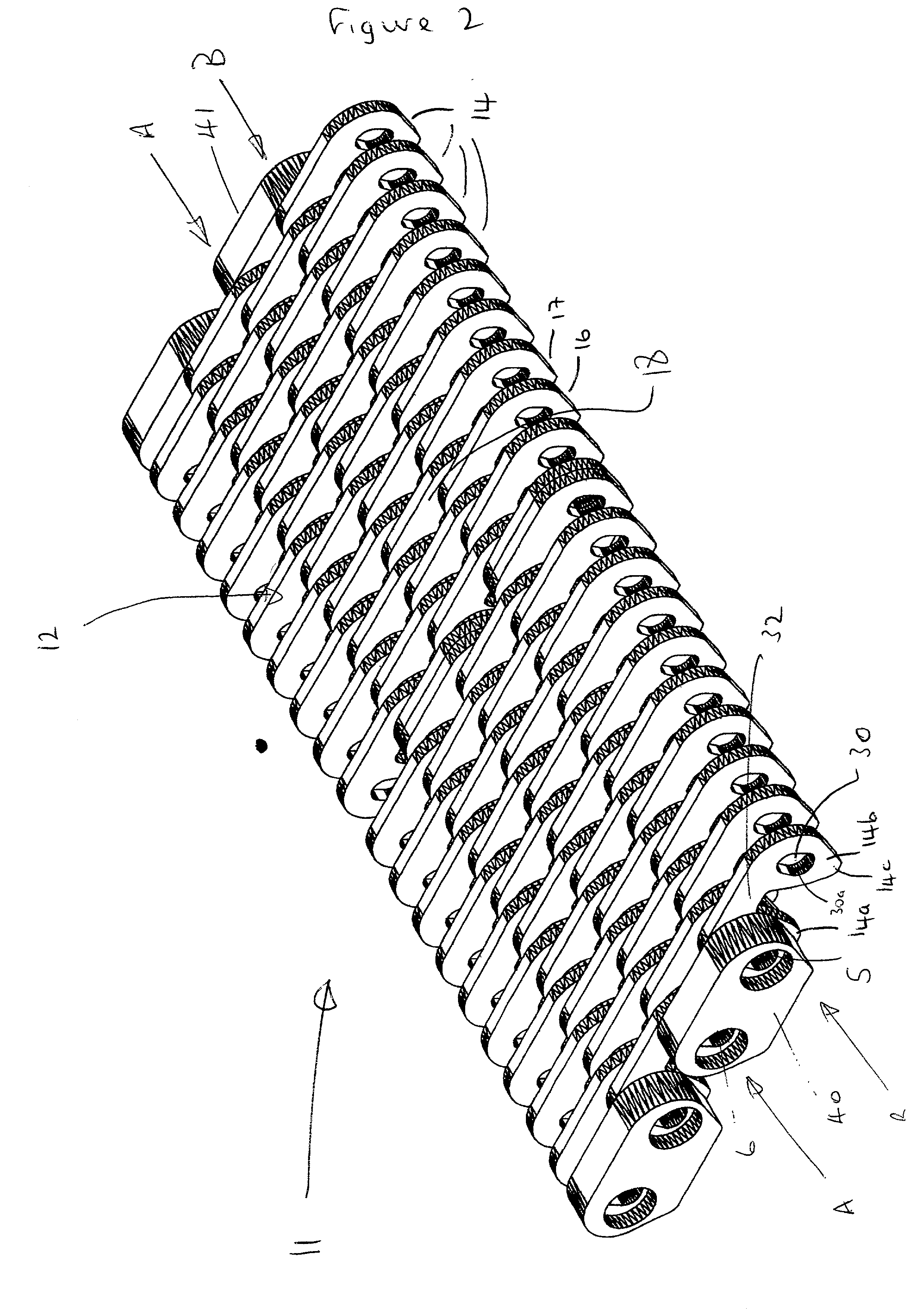

[0052] FIG. 2 illustrates in partial view an embodiment of the multi-link conveyor chain of the invention designated generally by reference numeral 11. For the sake of clarity, the elongate pins and washers are omitted from FIG. 2 (nevertheless it will be readily apparent how and where these are used).

[0053] The multi-link conveyor chain 11 provides a flat surface 12 upon which may be carried articles such as glass bottles to a processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com