Lens blanks for ophthalmic elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

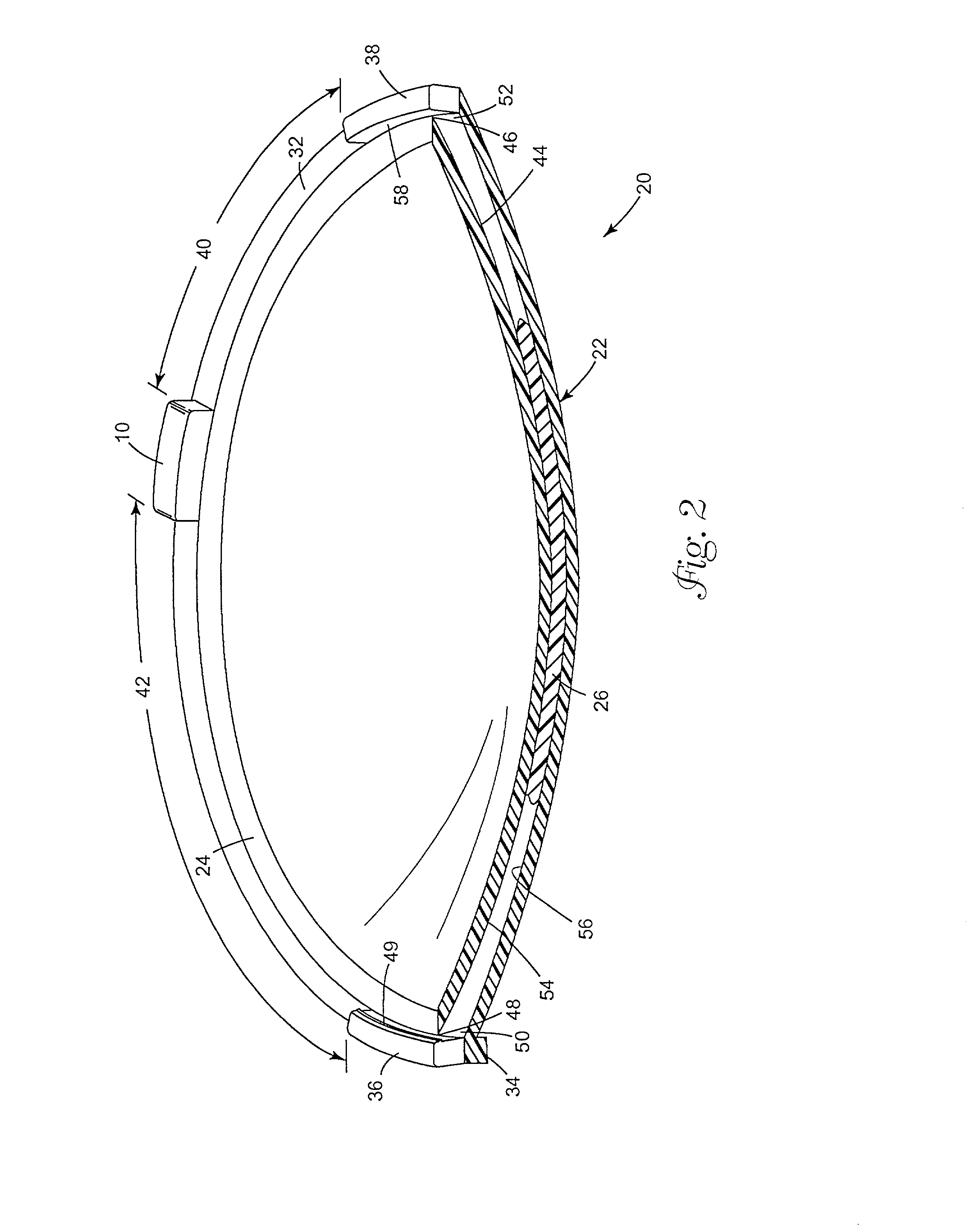

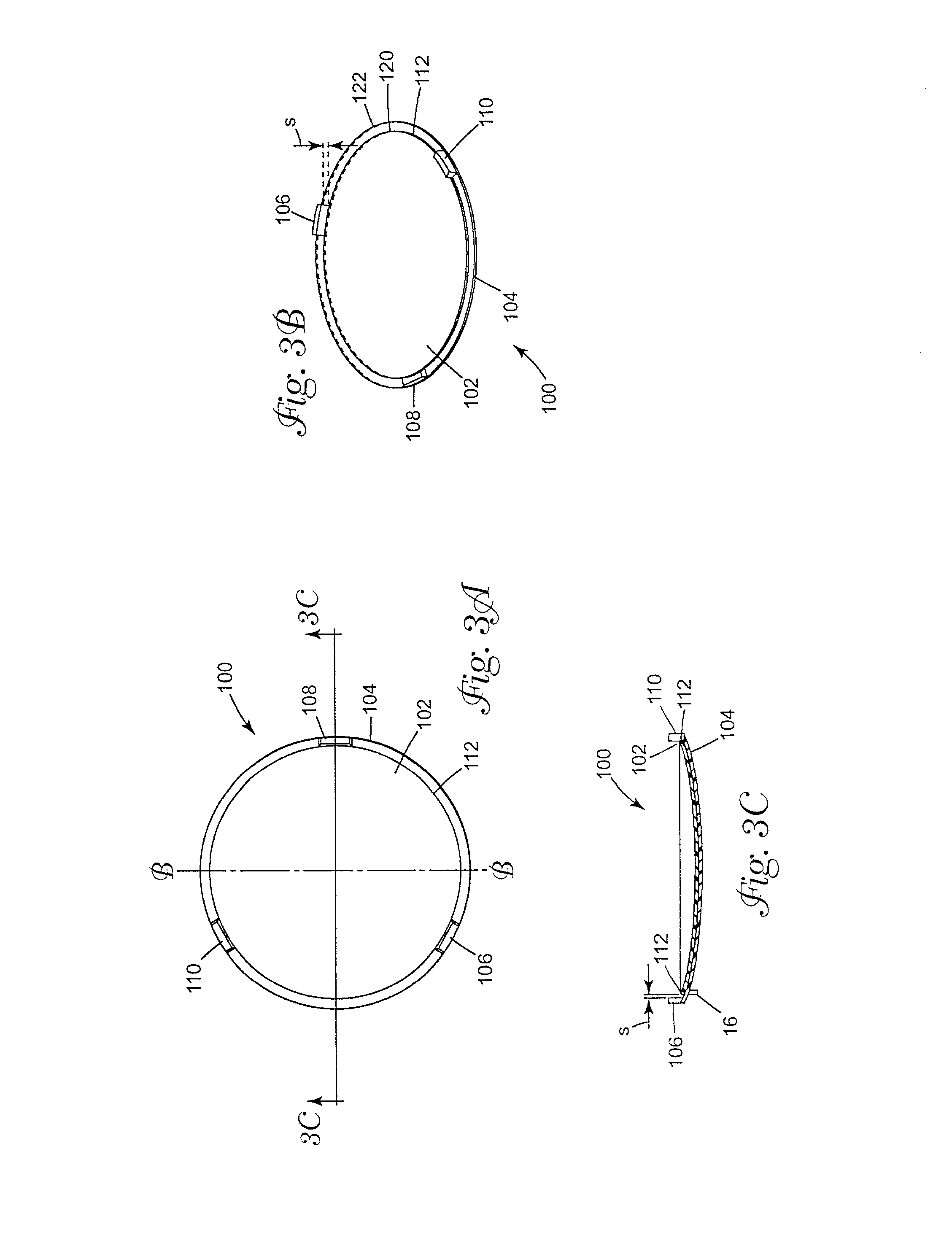

[0073] The lens wafers were molded consisting of 80 mm polycarbonate PAL front wafers and 75 mm polycarbonate SV back wafers. Each of the wafers was molded with a 0.8mm + / -0.10 mm center thickness. Three tabs were located 120.degree. apart around the outside edge of the back of the front wafers. These tabs were used to align the center of the two lens wafers.

[0074] Once molded, the wafers were checked for through power on the Humphry and the center thickness measured. The results are recorded in Tables 1 and 2 below.

1TABLE 1 Front wafer characteristics Center thickness, Lens ID Humphry base power Humphry add power c.t., (mm) 84412 -0.87 .times. -0.09 1.15 0.87 83412 -0.92 .times. 0.00 1.18 0.86

[0075]

2TABLE 2 Back wafer characteristics Center thickness, c.t., Lens ID Humphry base power (mm) LMA4.97 / 4.98 .times. 0.00 -0.3 .times. 0.00 0.84 LMA4.97 / 4.98 .times. 0.00 -0.1 .times. 0.00 0.84 LMA4.97 / 4.98 .times. 0.00 -0.02 .times. 0.00 0.87 LMA4.97 / 4.98 .times. 0.00 -0.01 .times. 0.00 0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com