Method of controlling a frequency converter of a reluctance machine

a technology of reluctance machine and frequency converter, which is applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, starter details, etc., can solve the problems of difficult in practice and expensive, harmful noise problems, and occasional noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

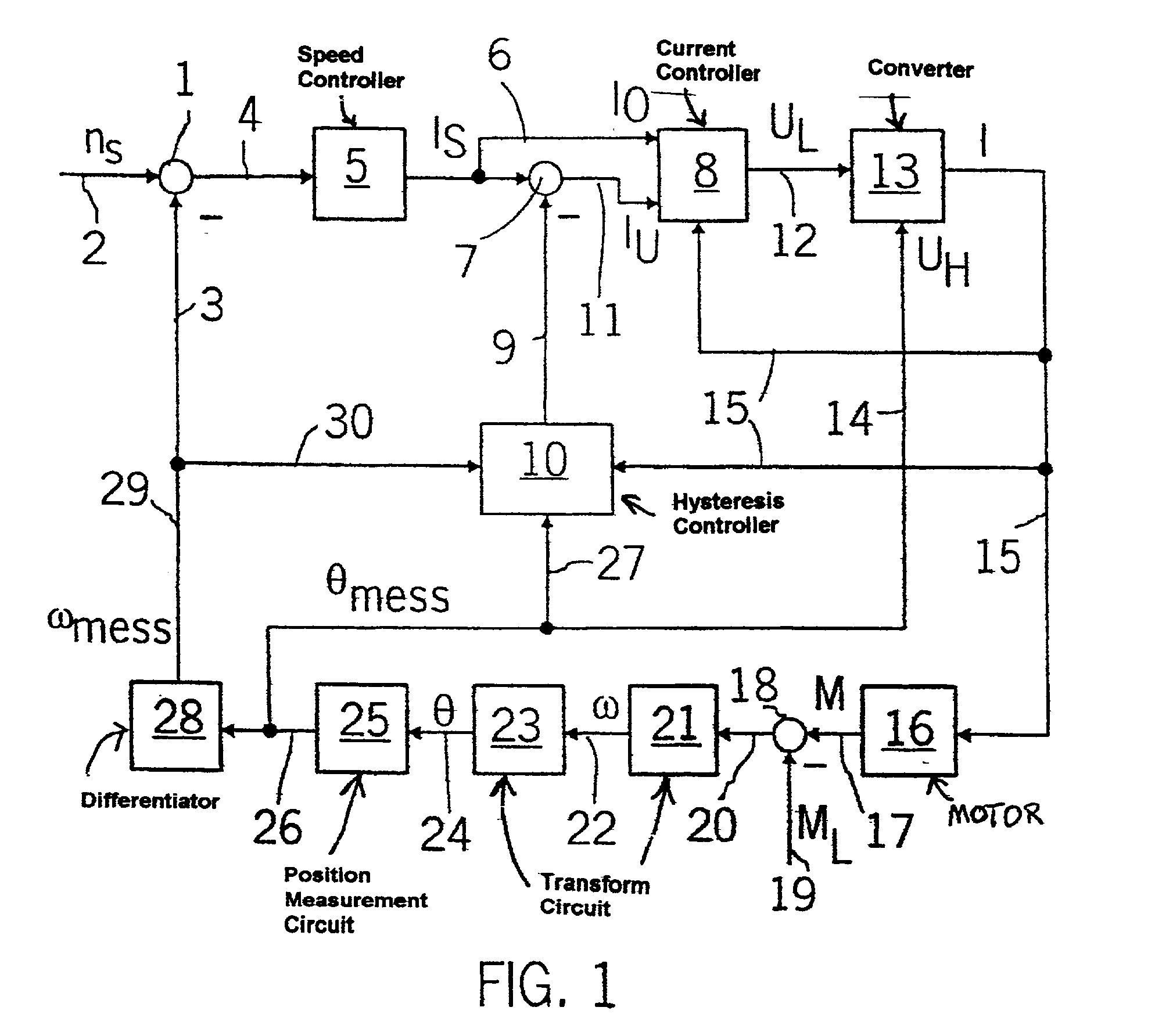

[0027] A set rotation speed n.sub.s is input to a summation point 1 with a positive sign on a line 2 and a measured rotation speed .omega..sub.mess is input to the summation point 1 with a negative sign on line 3 for rotation speed regulation. The resulting difference is supplied to a rotation speed controller 5 on a line 4. The rotation speed controller 5 converts this input into a set current value I.sub.s, which for example can correspond to the upper current threshold value I.sub.o of the hysteresis band. It is then supplied over the line 6 to both a current controller 8 and a second summation point 7 as the upper current set value I.sub.0 and as an input signal for the second summation point 7 respectively. An output signal from the hysteresis controller 10, which represents a current correction value, is fed to the second summation point 7 over the line 9 with the negative sign. A difference signal, which is fed over a line 11 to the current controller 8 as a second input sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com