Vibratory pile-driving device

a technology of vibrating piles and driving devices, which is applied in the direction of bulkheads/piles, soil preservation, construction, etc., can solve the problems of particularly undesirable noise radiation, and achieve the effects of high flexibility, high flexibility, and reliable follow-up of vibrating movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

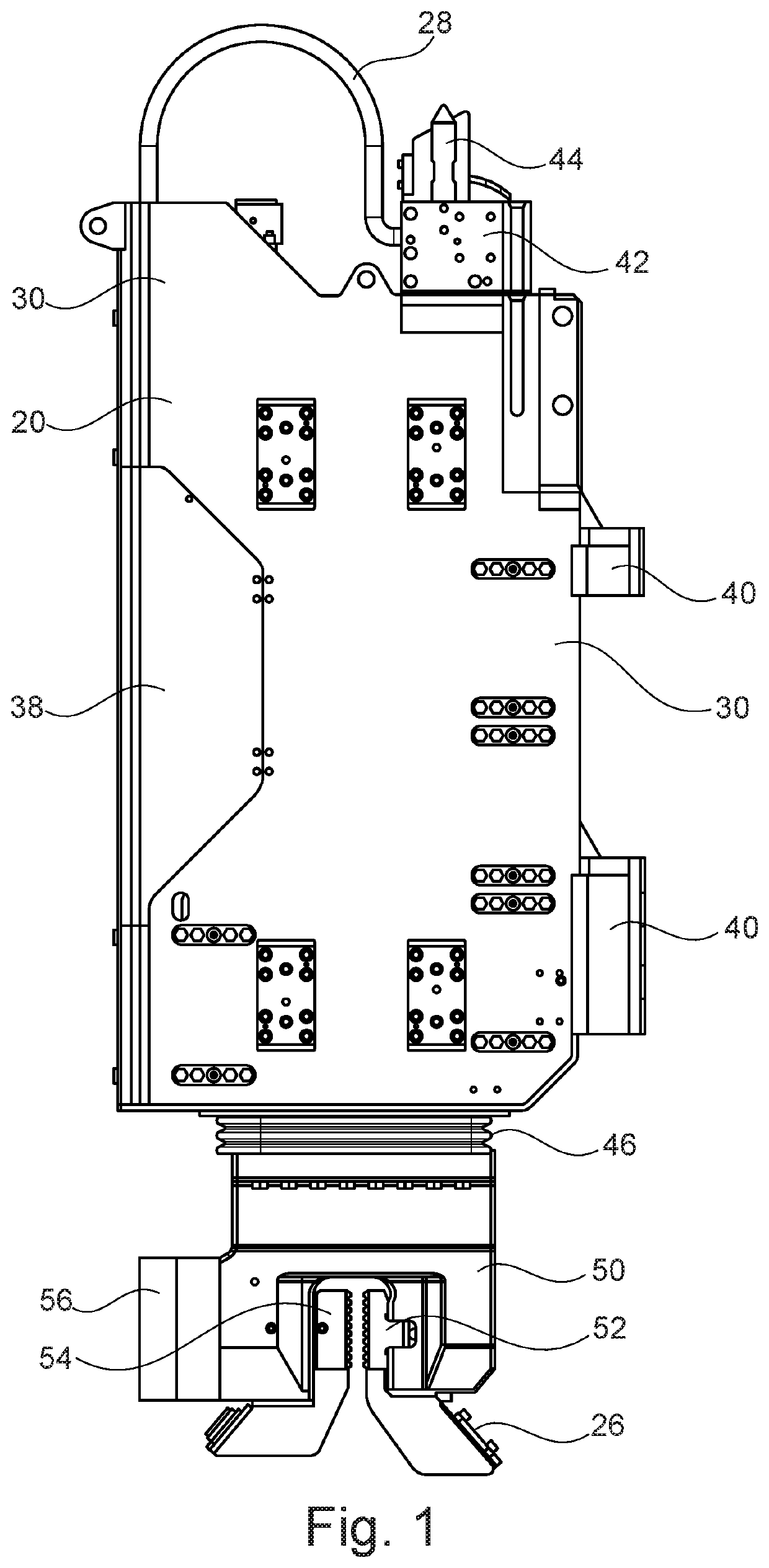

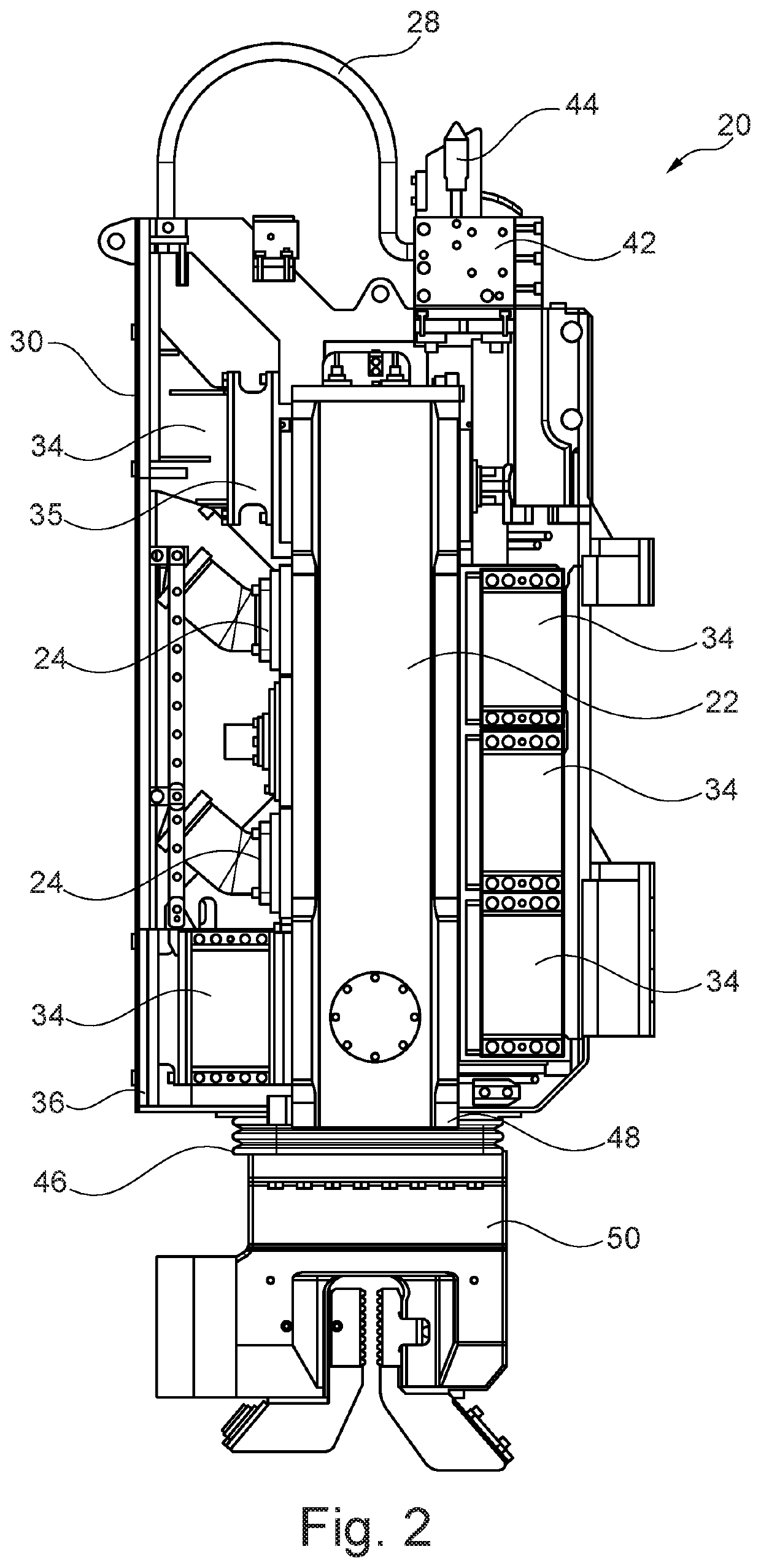

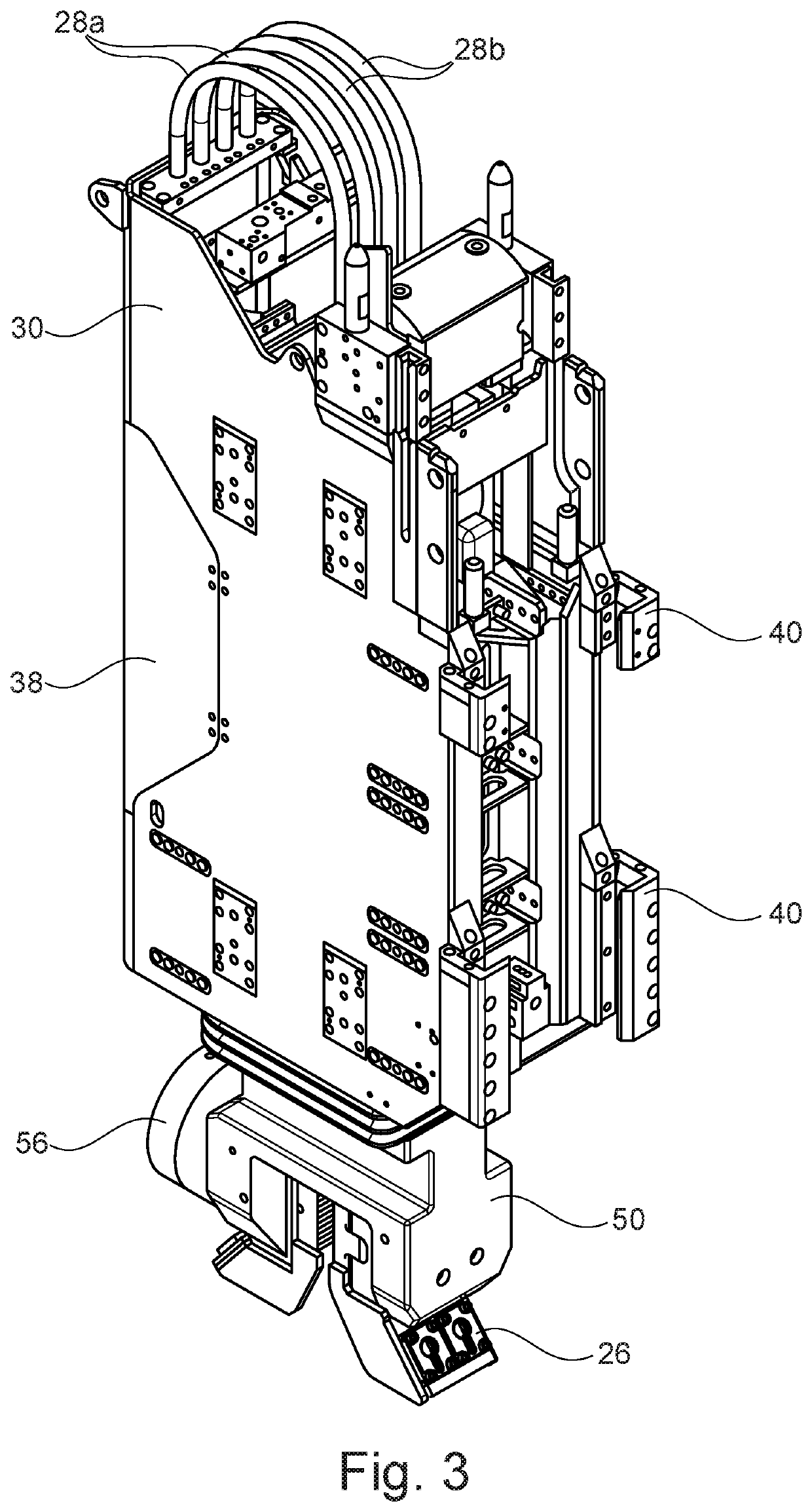

[0027]According to FIG. 5 a vibratory pile-driving apparatus 10 pursuant to the invention has a carrier implement 12 which comprises in a known manner a crawler-track running gear as an undercarriage and an upper carriage arranged thereon in a rotatable manner. On the upper carriage of the carrier implement 12 a mast 14 is linked in a pivotable manner which is designed as a leader with a lower mast part 15, along which an upper mast part 16 is guided in a vertically movable manner. Along a front side of the upper mast part 16 a linear guide 17 is designed, along which a vibration generator 20 according to the invention is guided by a guiding means 40.

[0028]On its upper side the vibration generator 20 is releasably coupled via a quick-coupling 41 to a feed carriage 18 that can be moved via a feed means along the linear guide 17 of the upper mast part 16. To form the quick-coupling 41 a lower quick-coupling unit 42 is arranged on the vibration generator 20, which establishes a connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com