Water purification system with automatic flush flow

a water purification system and automatic technology, applied in reverse osmosis, multi-stage water/sewage treatment, membranes, etc., can solve the problems of retentate or brine outflow from the ro membrane that is normally discarded other pre- and post-filter elements is typically limited, and the service life of the ro membrane is limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

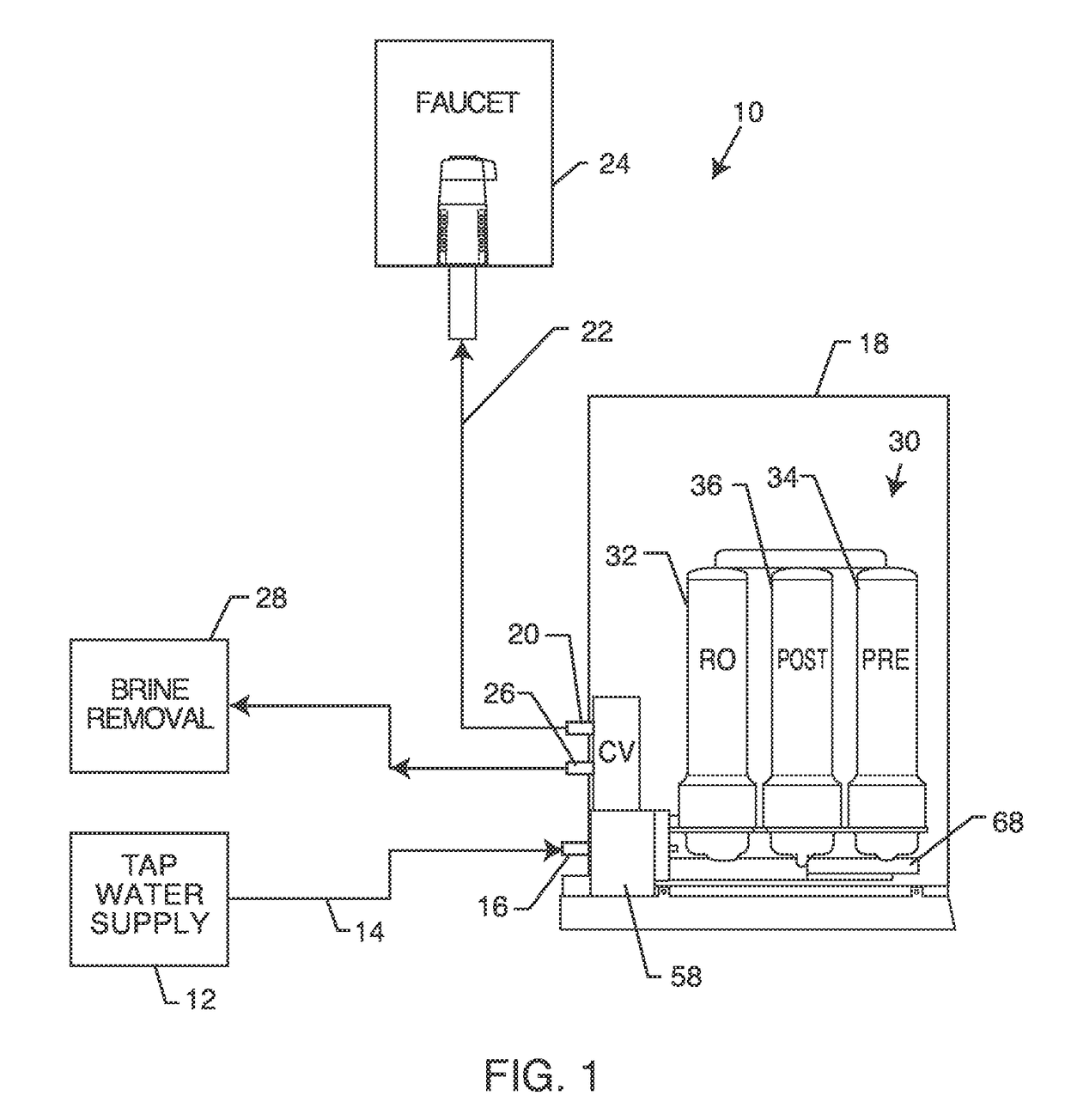

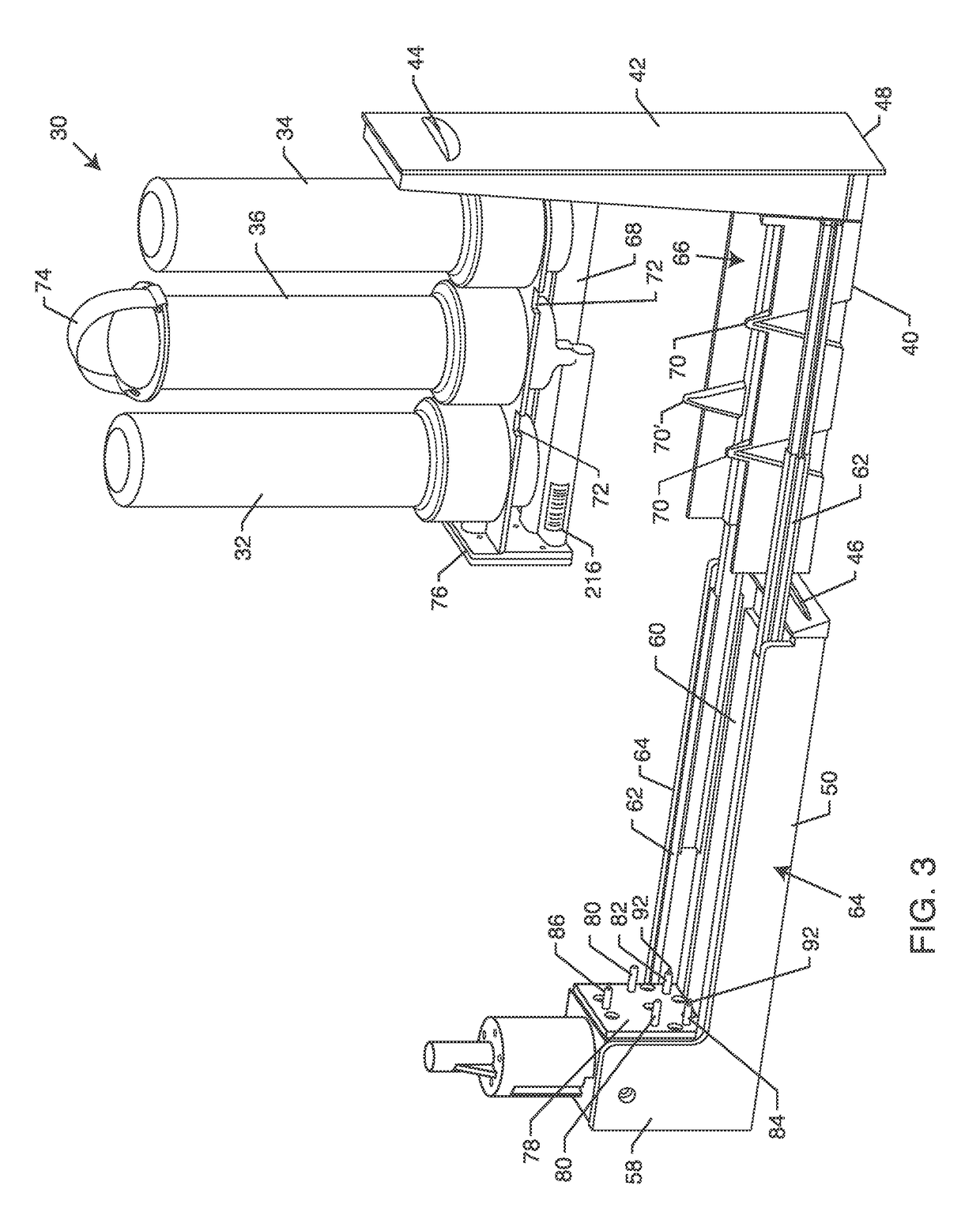

[0040]As shown in the exemplary drawings for purposes of illustration, an improved water purification system is referred to generally by the reference numeral 10 in FIG. 1. In general, the water purification system 10 disclosed herein is designed to provide improved filtration characteristics of the type of filtration systems that use reverse osmosis (“RO”) membrane-based water filtration cartridges and / or catalyst-based filtration cartridges. In this respect, the water filtration system 10 includes a flush-flow activation chamber that intermittently and automatically reenergizes the RO membrane and / or particulate catalyst by facilitating periodic rapid injection of tap water inflow to wash build-up off the RO membrane, which otherwise decreases membrane performance and service life, and to agitate the particulate catalyst. More specifically, the flush-flow activation chamber, as described in detail below, generates back pressure within the filtration system 10, the release of which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com