Closure for a container, especially a bottle

A technology for bottles and containers, applied in the directions of capping, sealing, closing, etc., which can solve the problems of inability to apply caps, insufficient elasticity or resilience, and inability to ensure release of pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

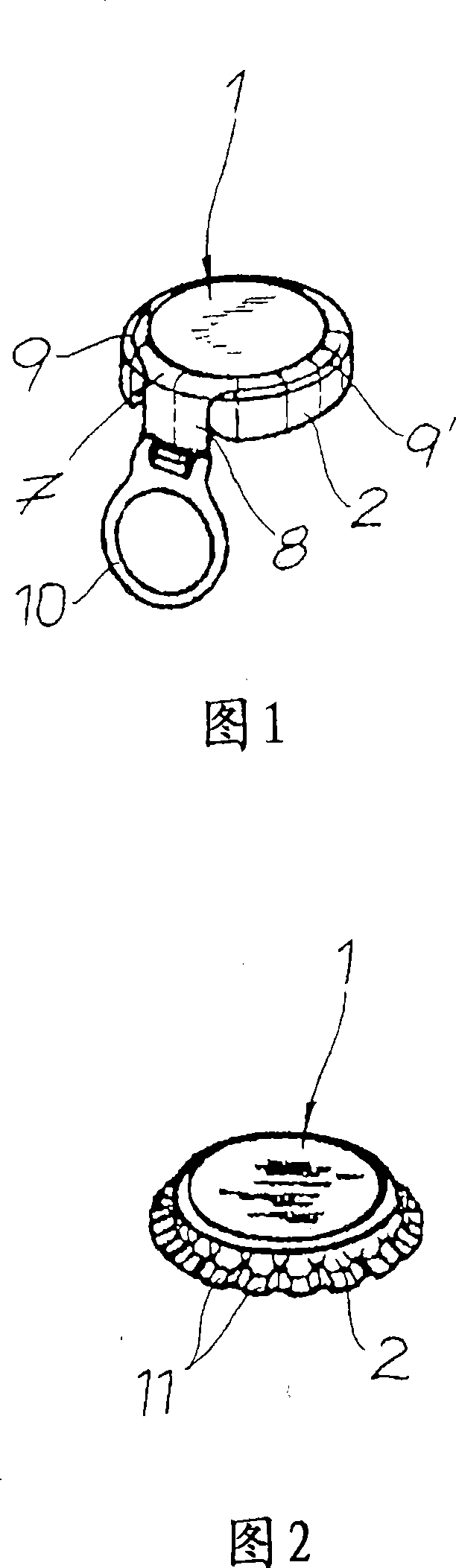

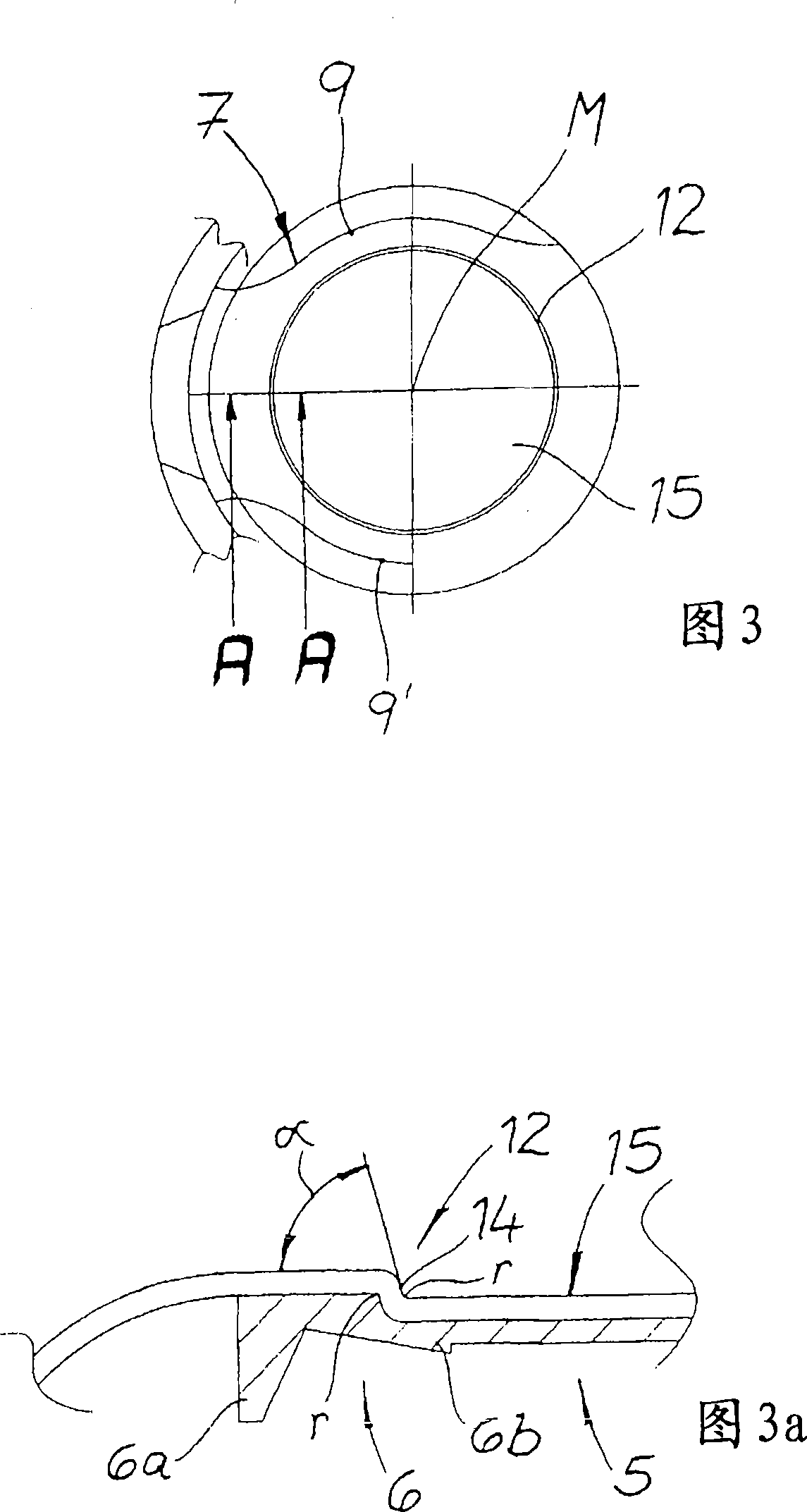

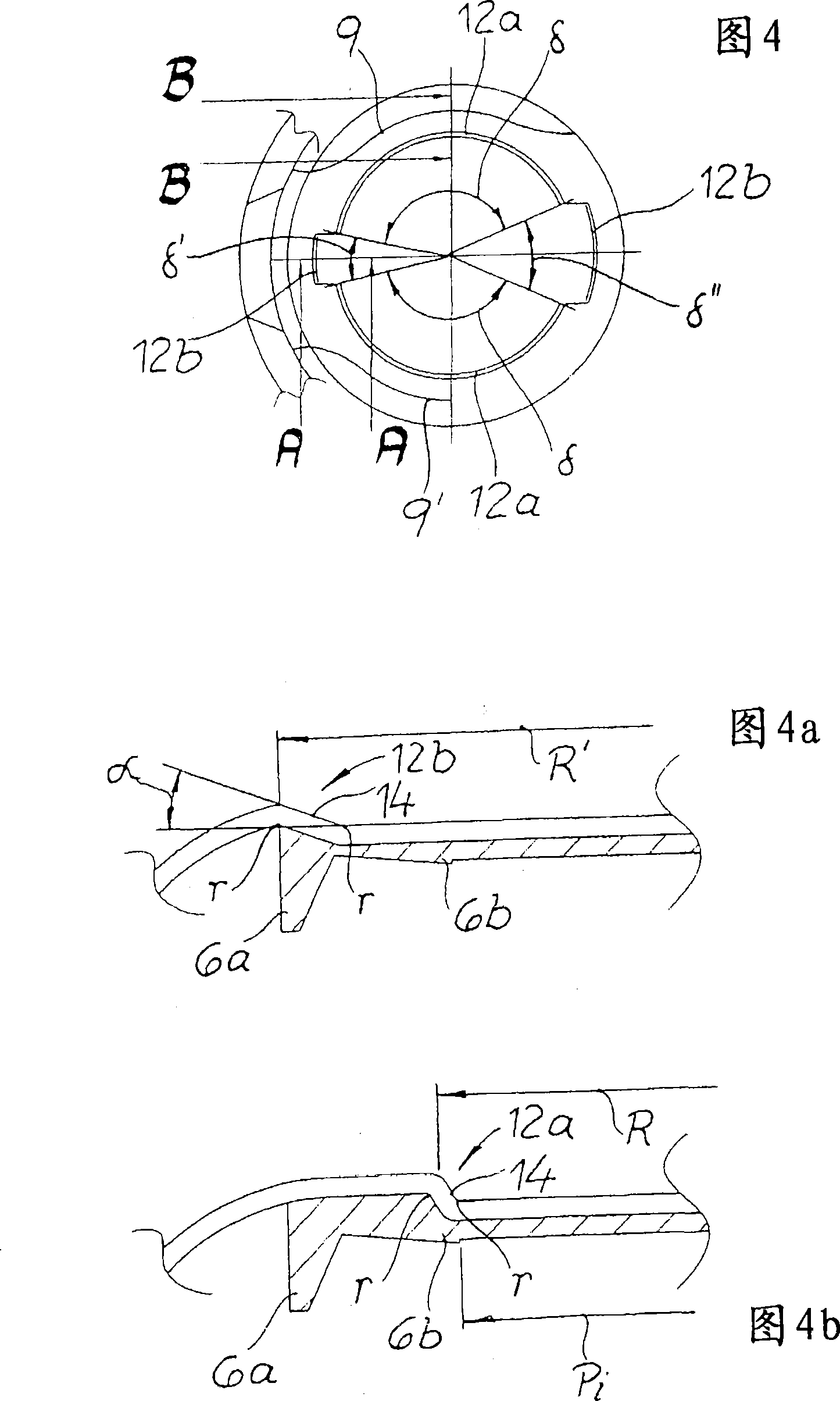

[0045] The figures show closures for bottle or other container openings. FIG. 1 shows the basic structure of a bottle cap as an example of a tear-off closure. The closure consists of an upper circular cover plate 1 adjacent to the outside of the cover plate 1 is a substantially cylindrical collar or skirt 2 which is crimped 4 over the neck 3 during the sealing and clamping process. Or surround the bottleneck 3 below the flange. A sealing gasket 5 (which is not visible in FIG. 1 ) is located on the underside of the cover plate 1 and has an annular profile seal 6 on the outer circumferential side. It can also be seen in FIG. 1 that the tear-off closure has a tear-off opening strip 7 with a tongue 8 protruding from the closure skirt 2 , wherein the tear-off strip is arranged on the closure The dashed lines 9, 9' in the limit. The dashes on both sides are generally of the same length, but can vary from half length 9' to full length 9. The tongue 8 is connected to a pulling ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com