Novel IC engine cylinder block apron

A technology for cylinders and cylinder blocks of internal combustion engines, which is applied in the directions of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of increased production cost of cylinder blocks, short engine life, large vibration and noise, etc., to reduce vibration and noise, reduce noise, The effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

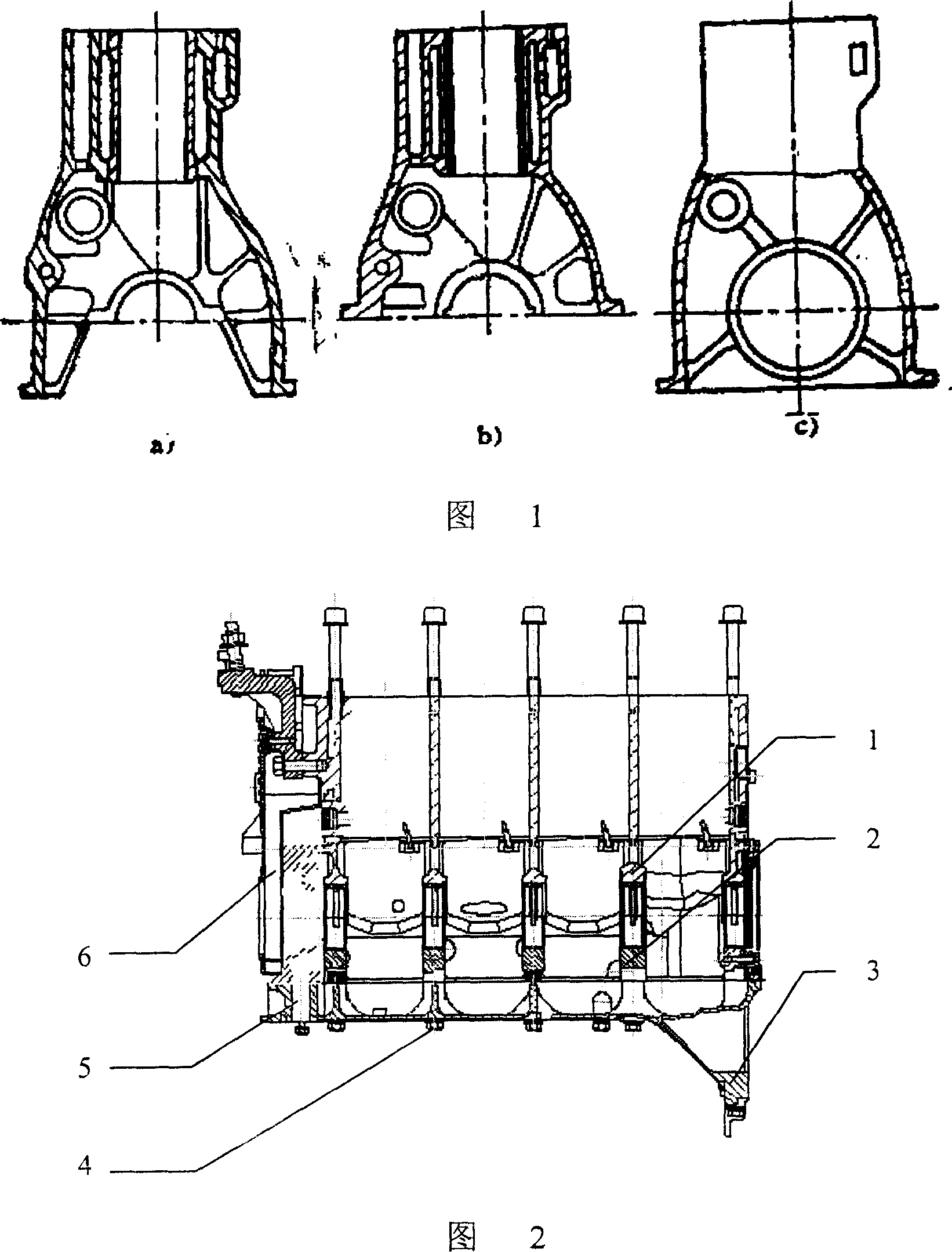

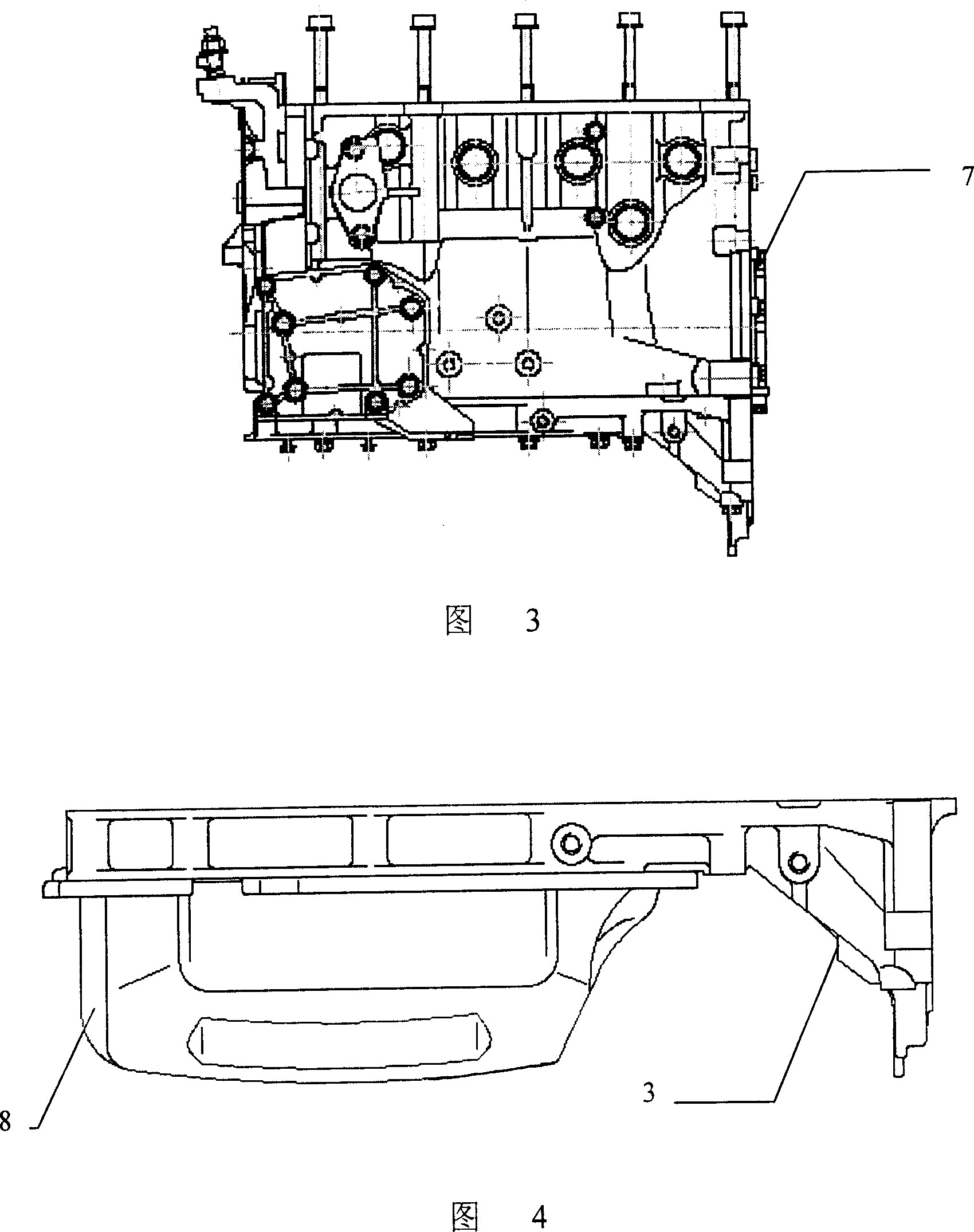

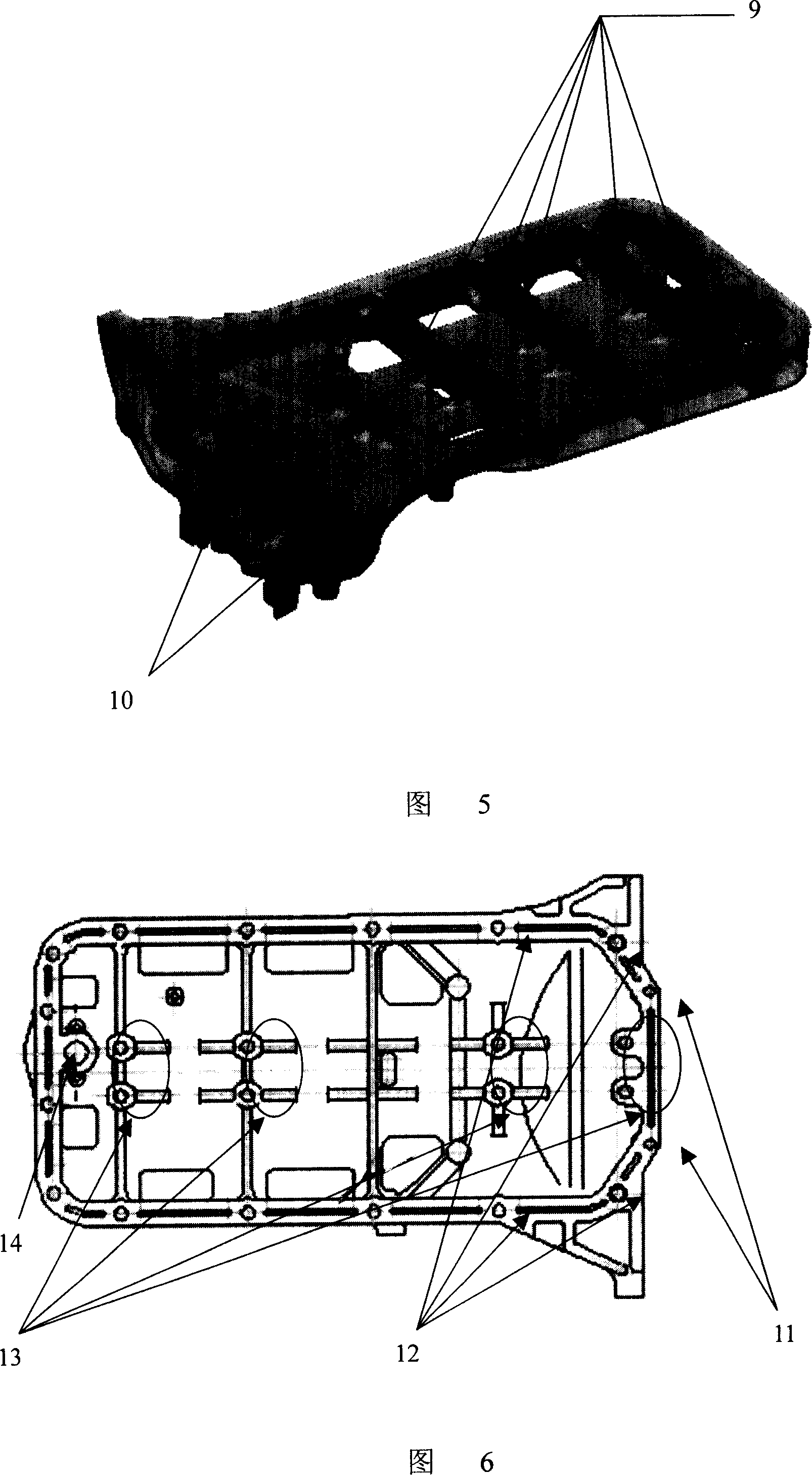

[0020] The cylinder block skirt 3 of the present invention is fixed on the lower bottom surface of the cast iron cylinder block by bolts, and the bottom surface of the cylinder body and the top surface of the skirt frame pass through the sealant groove 14 and rely on the sealant to ensure good sealing. As shown in Figures 2 to 4, in addition to being connected to the cylinder block 1, the cylinder block skirt frame 3 is also connected with the oil pump 6 and the rear oil seal cover assembly 7 to form a whole with the rear oil seal cover bolt hole 11 and is provided with The engine oil inlet hole 5; the cylinder block skirt frame 3 is provided with a bolt hole 17 for connecting the oil pump oil pan, and an oil collector bolt hole 16 is installed to connect the oil collector and the oil pan 8. Constitute the crankcase system of engine like this, and the cylinder body skirt frame 3 has played the effect of linking up and down. The cylinder block 1 part supported by the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com