Assembled architecture outer wall and its construction method

A kind of building exterior wall, prefabricated technology, applied in the direction of building, building components, building structure, etc., can solve the problems of low level of building industrialization, troublesome operation methods, slow construction speed, etc., and achieve good practical application value and social promotion significance. , Reduce the investment of manpower and material resources, and the installation process is convenient and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The prefabricated building exterior wall of the present invention includes a load-bearing component and an enclosure plate arranged on the load-bearing component.

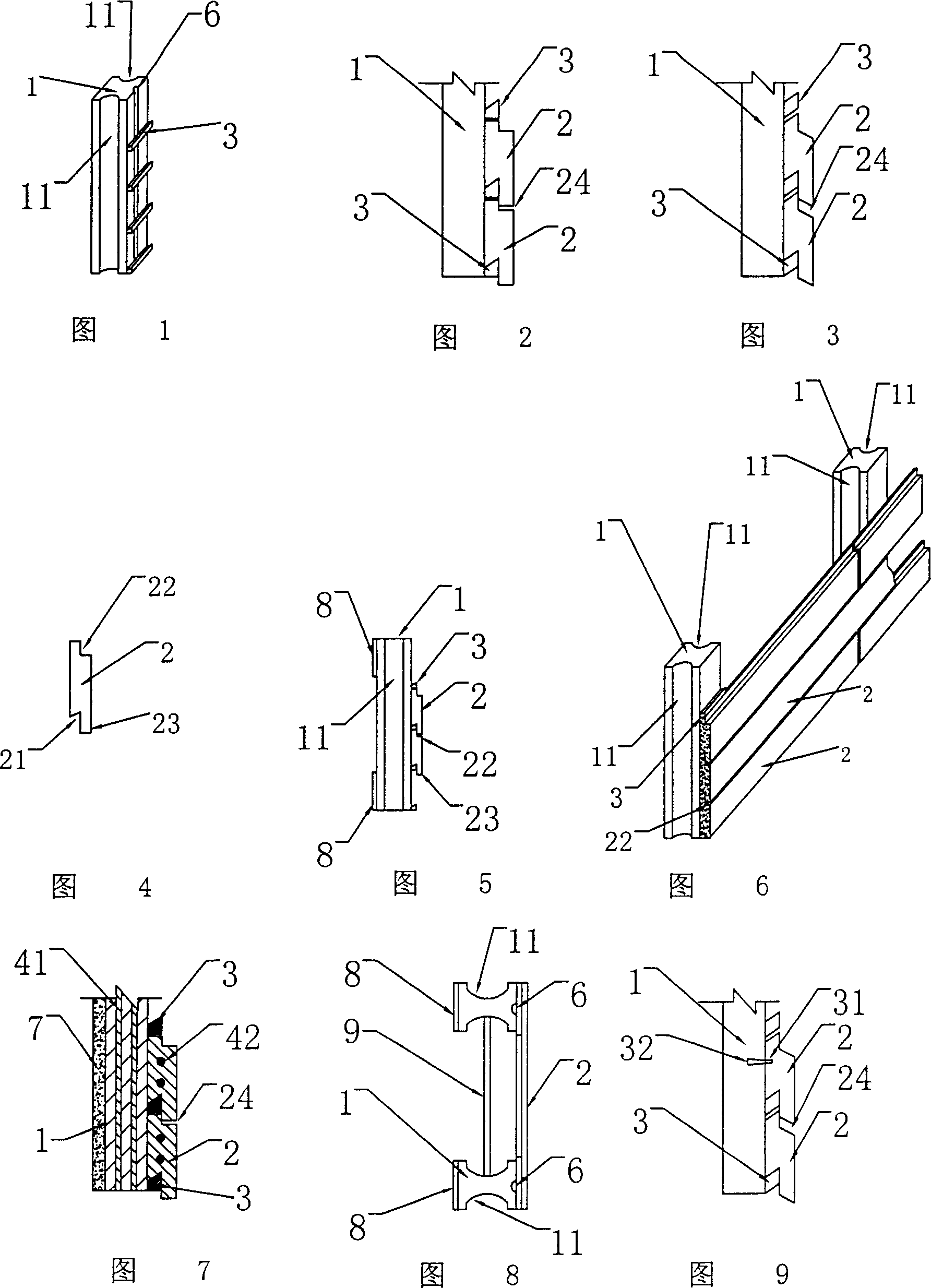

[0041] Figure 1 shows the load-bearing member, including a plurality of columns 1, each column 1 outer surface is fixed with a number of hanging keys 3 protruding outwards, the outer side of the column 1 is provided with a drip groove 6, the column 1 The two sides are respectively provided with grooves 11 that penetrate up and down;

[0042] Fig. 2, Fig. 4 show described fence, and fence is made up of many hanging boards 2, and hanging board 2 is hung on the hanging key 3 of column 1, and the inner side of hanging board 2 bottoms has the same shape as hanging key 3. Cooperating hanging groove 21, the outside of the top is provided with tongue and groove 22, and the bottom is the overlap joint 23 that cooperates with the tongue and groove 22 that bottom adjacent hanging plate is provided with on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com