Negative ions far infrared ray composite viscose fiber and its production process

A far-infrared, viscose fiber technology, applied in the field of viscose fiber, can solve the problems of difficult production, single fiber composition, no negative ions, etc., and achieve the effects of simplifying the production process, enhancing metabolism, and enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

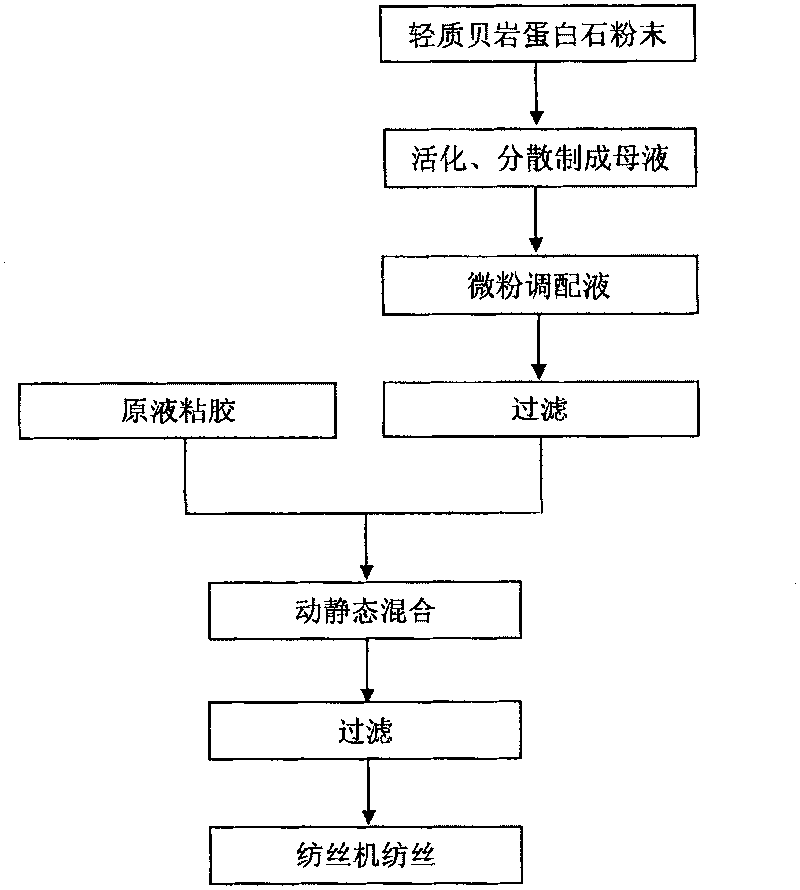

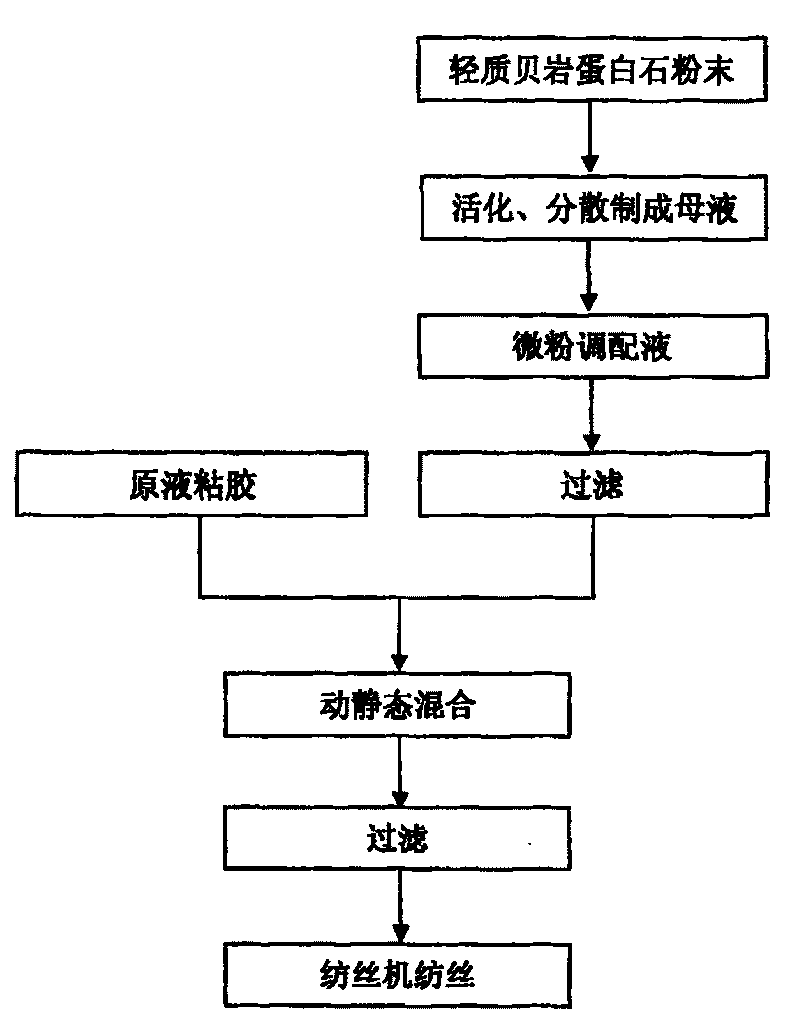

Image

Examples

Embodiment 1

[0041] A kind of production technology of negative ion far infrared ray composite viscose fiber is characterized in that the steps are:

[0042] A, the preparation of stock solution viscose;

[0043] B, the preparation of light shell rock opal powder mother liquor: by powder: the ratio of water=1: 1.5, the addition of dispersant is added by making 0.5% of mother liquor, and its specific steps are as follows:

[0044] (1), first put deionized water in the mother liquor blending tank;

[0045] (2), then add light shell rock opal powder, while stirring, slowly pour into the water;

[0046] (3), while stirring, slowly add half of the total amount of dispersant;

[0047] (4), the product obtained in (3) was ground for 0.5 hour;

[0048] (5), add the remaining half of the dispersant, continue to grind for more than 0.5 hours, and prepare the mother liquor of light shell rock opal powder;

[0049] C. Preparation of negative ion far-infrared ray blending liquid: the content of lig...

Embodiment 2

[0074] A kind of production technology of negative ion far infrared ray composite viscose fiber is characterized in that the steps are:

[0075] A, the preparation of stock solution viscose;

[0076] B, the preparation of light shell rock opal powder mother liquor: press powder: the ratio of water=1: 2, the addition of dispersant is added by making 1% of mother liquor, and its specific steps are as follows:

[0077] (1), first put deionized water in the mother liquor blending tank;

[0078] (2), then add light shell rock opal powder, while stirring, slowly pour into the water;

[0079] (3), while stirring, slowly add half of the total amount of dispersant;

[0080] (4), grinding the product obtained in (3) for 0.5 to 3 hours;

[0081] (5), add the remaining half of the dispersant, and continue grinding for more than 0.5 hours;

[0082] C. Preparation of negative ion far-infrared ray blending solution: the content of light shell rock opal powder is prepared according to 8%,...

Embodiment 3

[0107] A kind of production technology of negative ion far infrared ray composite viscose fiber is characterized in that the steps are:

[0108] A, the preparation of stock solution viscose;

[0109] B, the preparation of light shell rock opal powder mother liquor: press powder: the ratio of water=1: 2.5, the addition of dispersant adds by making 1.5% of mother liquor, and its specific steps are as follows:

[0110] (1), first put deionized water in the mother liquor blending tank;

[0111] (2), then add light shell rock opal powder, while stirring, slowly pour into the water;

[0112] (3), while stirring, slowly add half of the total amount of dispersant;

[0113] (4), the product obtained in (3) was ground for 1 hour;

[0114] (5), add the remaining half of the dispersant, continue to grind for more than 0.5 hours, and prepare the mother liquor of light shell rock opal powder;

[0115] C. Preparation of negative ion far-infrared preparation liquid: the content of light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com