Processing method of heavy metal pickling sewage or acid sewage

A technology of acid sewage and treatment method, applied in the direction of metallurgical wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of incomplete coagulant reaction, coagulant waste, secondary pollution, etc., and achieve the effect of sewage treatment Good, the effect of small dosage of medicine and less residual substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

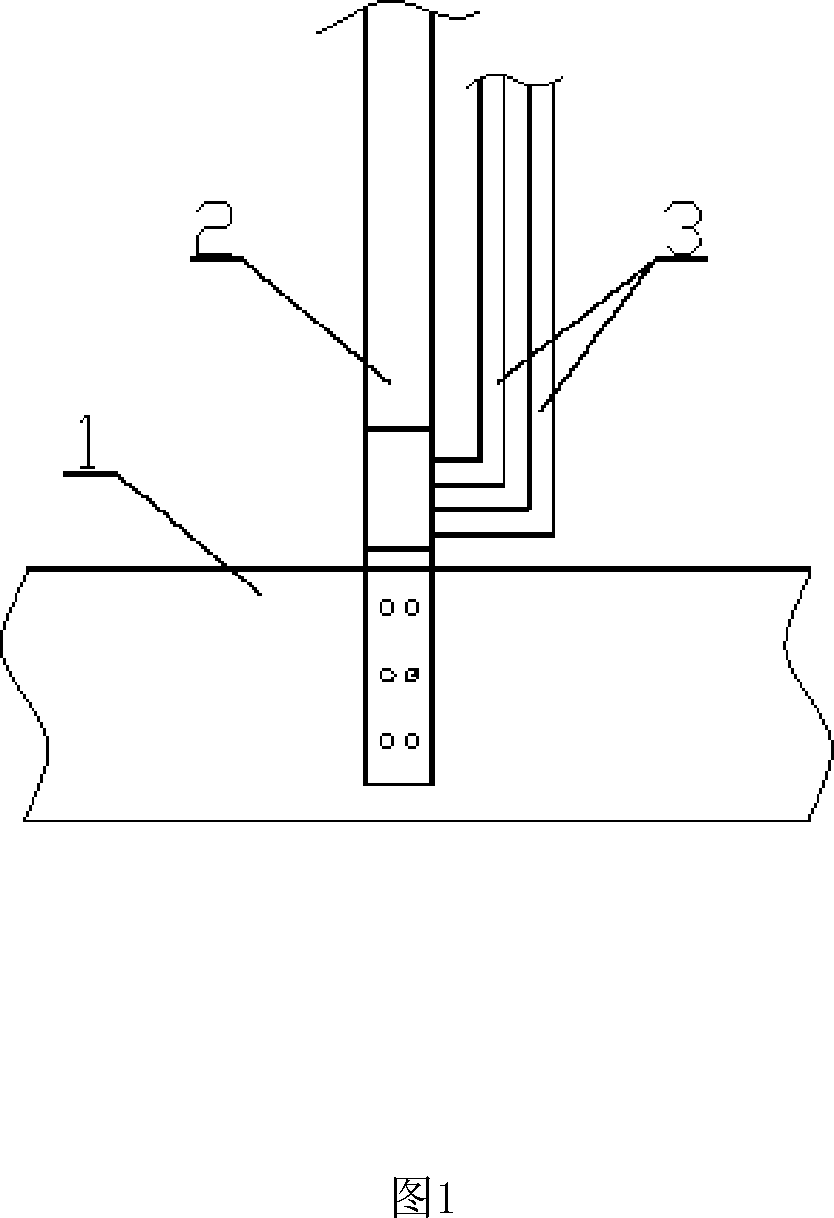

[0013] In the embodiment of the present invention, as shown in Figure 1, a dosing pipeline 2 is set on the sewage pipeline 1 of the flowing heavy metal pickling sewage or acid sewage, and an additional pipeline 3 is connected to the side of the dosing pipeline 2, through dosing Pipeline 2 adds coagulant, and the added coagulant is calcium hydroxide and can also be magnesium hydroxide, potassium hydroxide, sodium hydroxide or aluminum hydroxide. And add composite elements through additional pipe 3, the added composite elements are diatomite and can also be bentonite, zeolite, polyacrylamide, diallyl dimethyl ammonium chloride, diallyl dimethyl ammonium chloride or acrylic amine copolymers. For every 1000 parts of calcium hydroxide, magnesium hydroxide, potassium hydroxide, sodium hydroxide or aluminum hydroxide added through the dosing pipeline 2 in parts by mass, 2 parts of diatomite, bentonite, zeolite, poly Acrylamide, diallyl dimethyl ammonium chloride, diallyl dimethyl am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com