Plasma cutter

A cutting device, plasma technology, applied in the direction of plasma welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of reduced cutting surface quality, poor fluidity, etc., and achieve the effect of good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

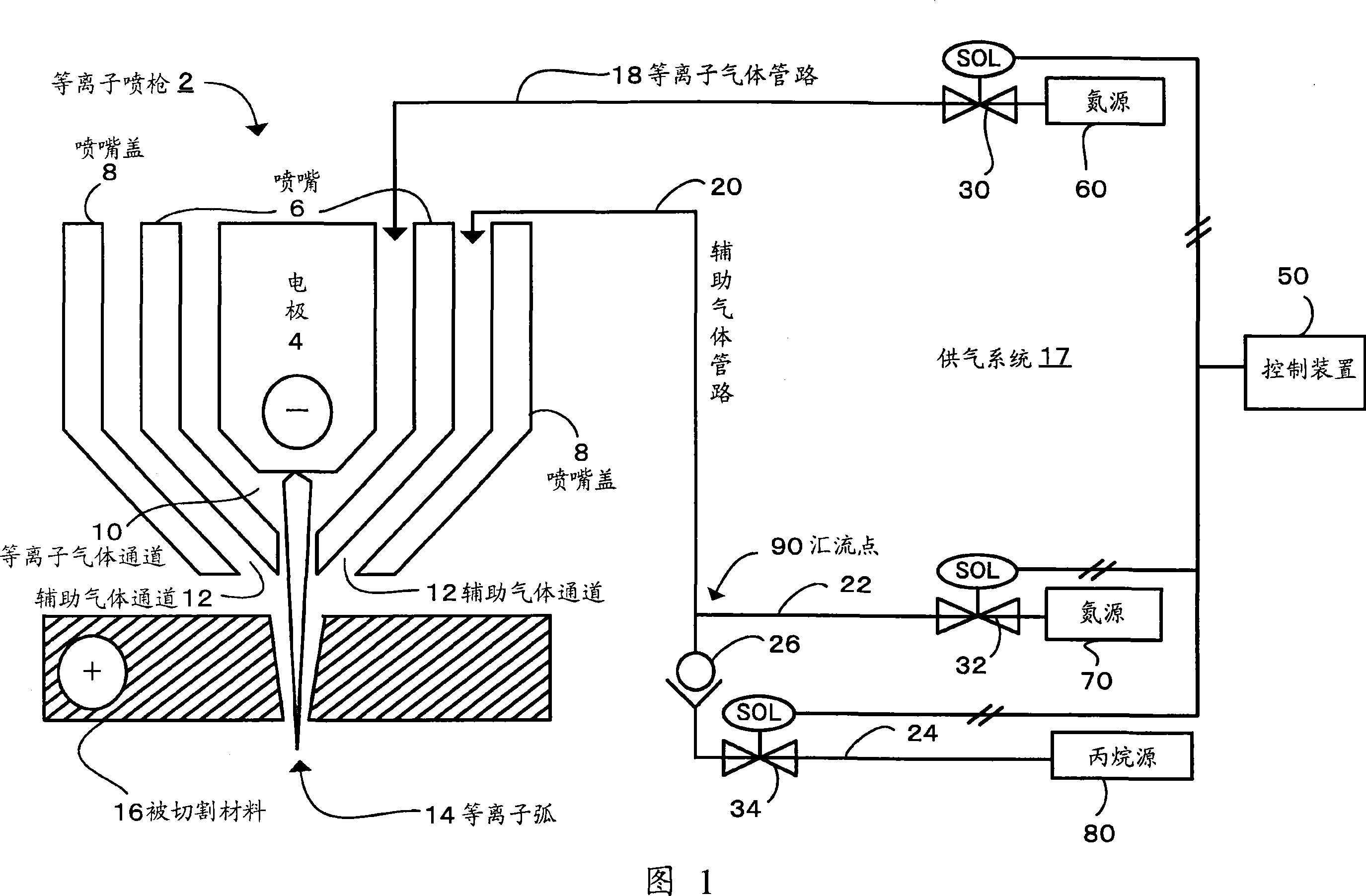

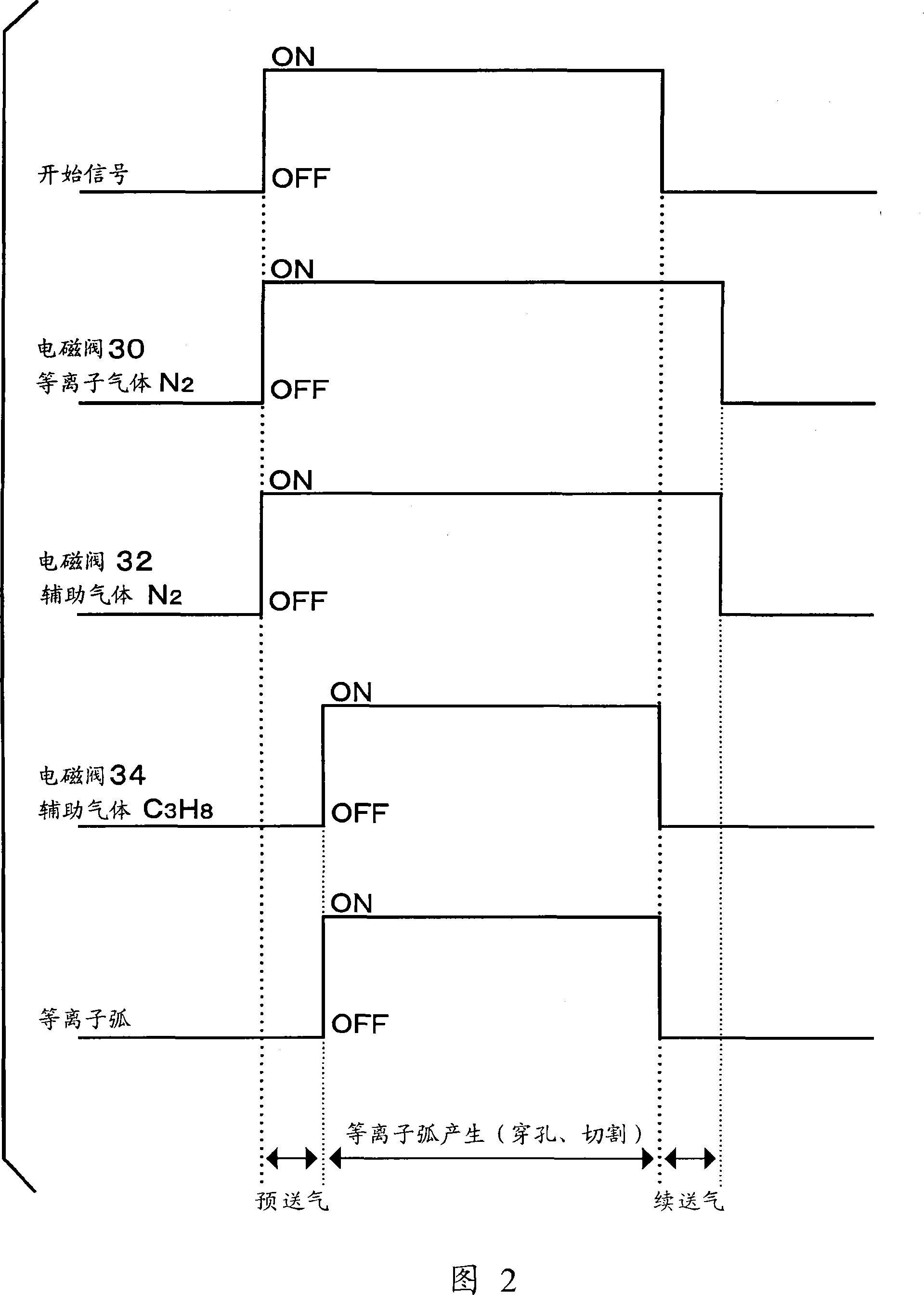

[0027] Embodiments of the present invention will be described below with reference to the drawings. As described below, this embodiment uses an inert gas such as nitrogen as the plasma gas, and uses a combustible gas with a specific gravity heavier than air and has reducing properties or a mixture of the combustible gas and an inert gas, such as a mixture of nitrogen and propane, as an auxiliary gas. Thereby stainless steel can be cut to obtain good quality.

[0028] FIG. 1 is a schematic configuration diagram of a plasma cutting apparatus according to an embodiment of the present invention.

[0029] As shown in FIG. 1 , the plasma torch 2 is in the shape of multiple cylinders as a whole, with an electrode 4 at its center, a nozzle 6 around the outside of the electrode 4 , and a nozzle cover 8 around the outside of the nozzle 6 . A gas supply system 17 is connected to the plasma torch 2 .

[0030] The gas supply system 17 includes: a plasma gas pipeline 18 for supplying plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com