Roughed plate bloom temperature control method in hot-rolled process

A temperature control method and technology for the hot rolling process, which are applied in temperature control, special data processing applications, instruments, etc., and can solve problems such as the correction of model coefficients by region.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

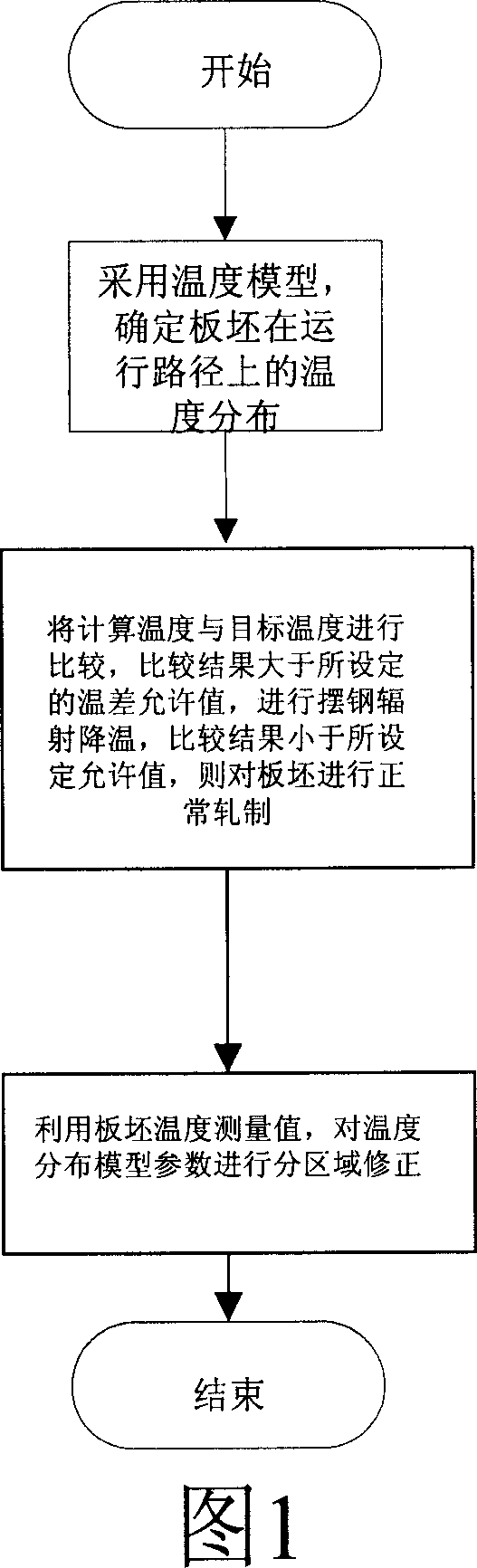

[0055] Please refer to Figure 1, the temperature control method includes the following steps:

[0056]a. First, take the temperature distribution when the slab is drawn out from the heating furnace as the starting point, and use the recursive analytical temperature distribution model according to the movement sequence and running time of the slab to obtain the temperature distribution at each point on the slab rolling path ;

[0057] b. Then, compare the average temperature of the slab at the measurement point after the rough rolling obtained in step a with the rough rolling target temperature. If the comparison result is greater than the set allowable value of the difference between the two temperatures, then The entrance temperature of the last pass of rough rolling is used as a reference, the steel is swayed, and the slab is radiated to cool down. If the comparison result is less than the set temperature allowable value, the slab is rolled normally;

[0058] c. Compare the meas...

Embodiment 2

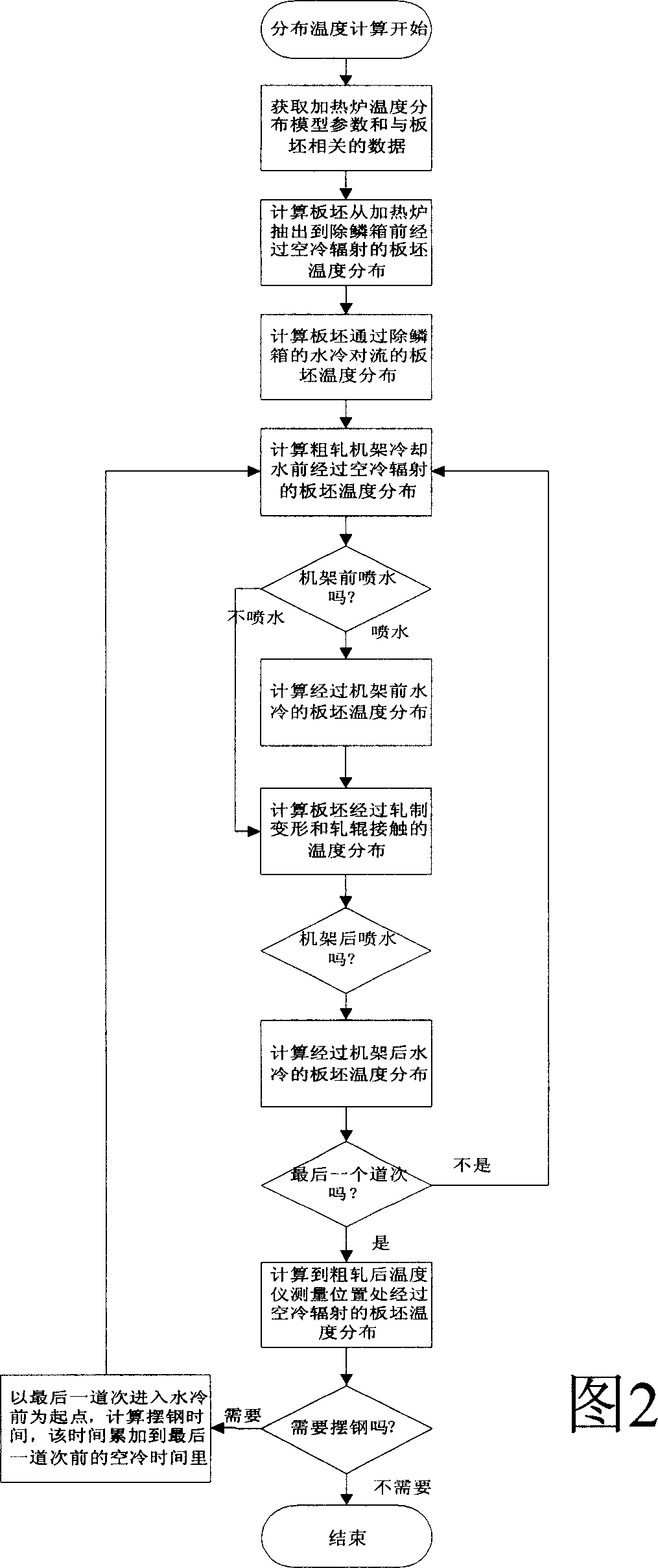

[0163] Please refer to FIG. 2. The steps of this embodiment are specifically described as follows:

[0164] First, obtain the temperature distribution model parameters of the slab drawn from the heating furnace and the data determined by the rolling process, such as slab thickness, slab physical parameters, slab running speed, and water spray mode.

[0165] The recursive analytical model is used to obtain the temperature distribution of the air-cooled radiation of the slab before reaching the scale box. Two parameters are involved in the calculation process, one is the running time of the slab, and the other is the radiation coefficient. They are all definite, because Whether it is an air-cooled zone or a water-cooled zone, its length is known, so the running time of the slab in the corresponding zone can be predicted, and the emissivity is known as a model parameter.

[0166] The slab temperature distribution of the water-cooled convection when the slab passes through the descali...

Embodiment 3

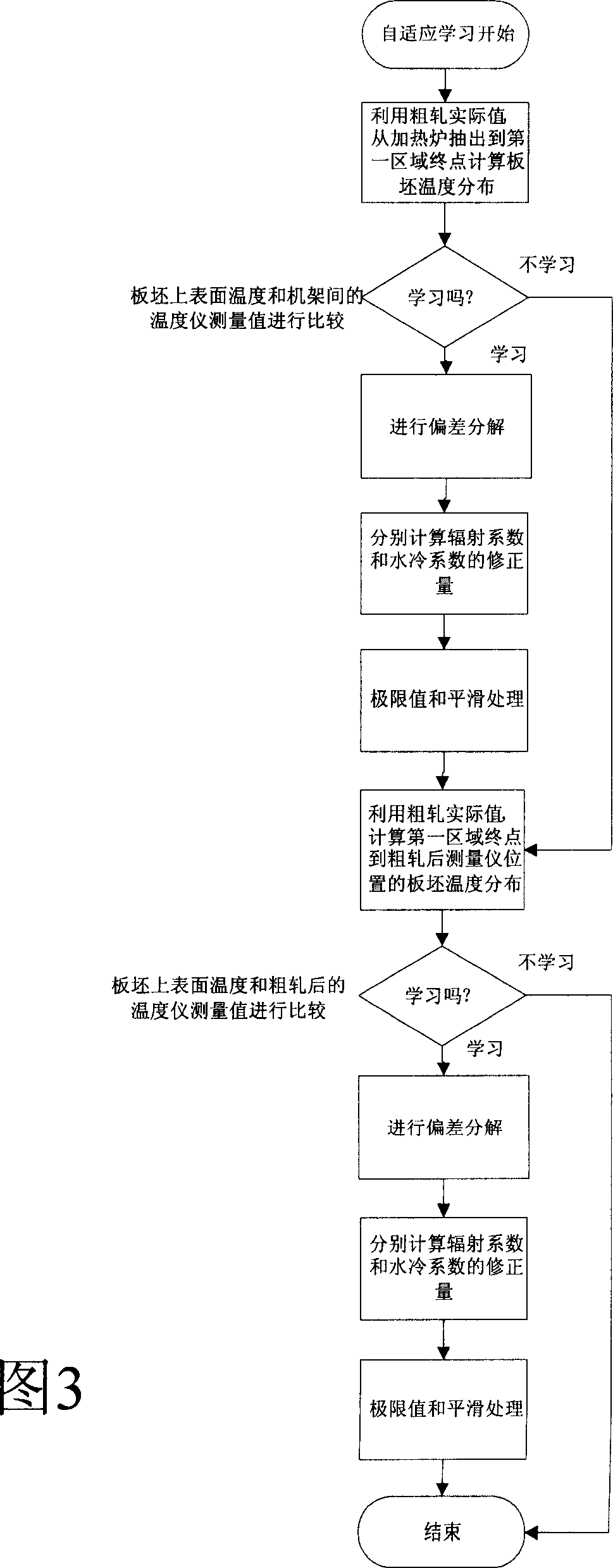

[0170] In the following, in conjunction with Fig. 3 and Fig. 4, the process of correcting the radiation coefficient and the water cooling coefficient by the slab temperature distribution model of the control method of the present invention will be explained.

[0171] After obtaining the relevant data of the passes of the newly rolled steel, such as obtaining the actual water spray status of the racks of each pass, the conveying time of the slabs in each air cooling zone, etc., use the control steps described in the second embodiment to obtain the rack R1 The temperature distribution of the slab at the end of the first zone in the last pass is shown in Figure 4, that is, the temperature distribution of the slab at the position of the temperature measuring instrument between the frame R1 and the frame R2. Using the actual value of rough rolling, the slab temperature distribution is obtained from the heating furnace extraction to the end of the first zone, and the slab surface temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com