Method for producing programmable device

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increasing production costs, increasing process steps and process integration complexity, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

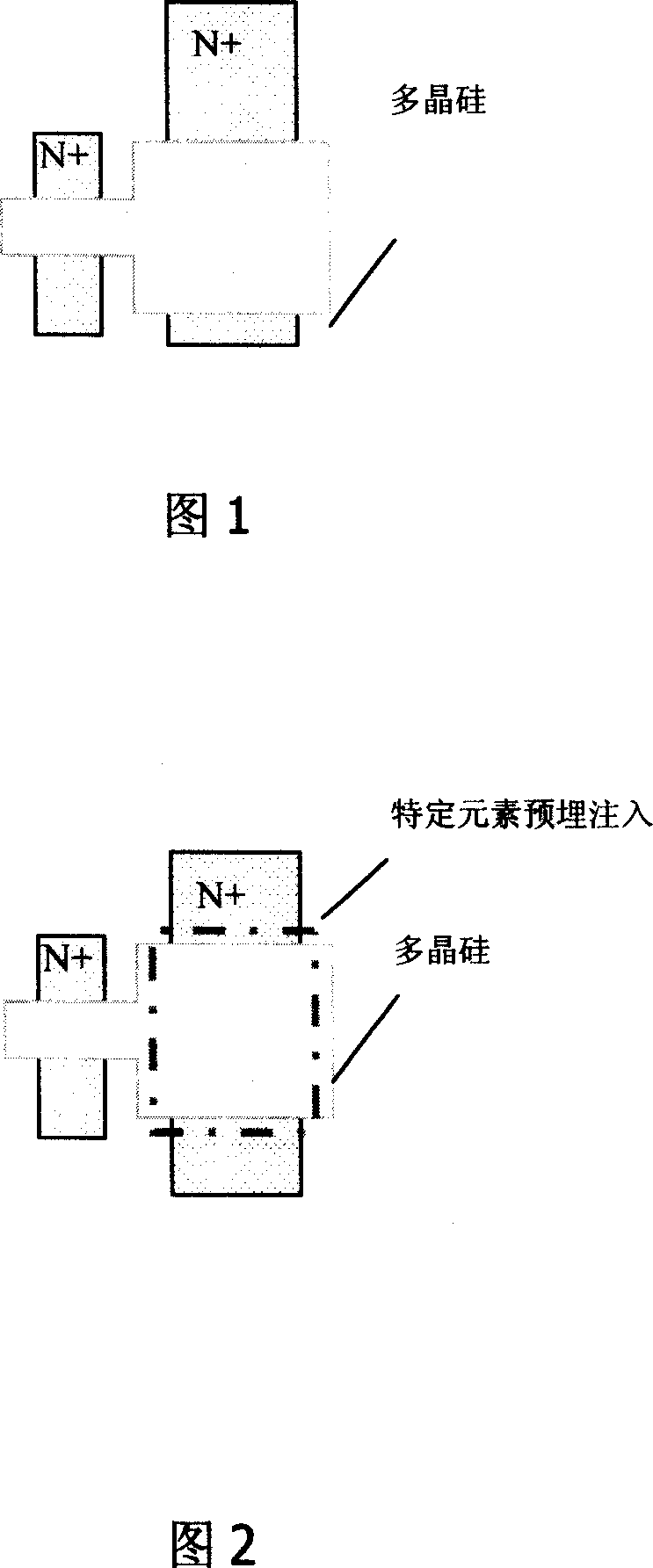

[0010] Fig. 2 is a schematic diagram of the structure of the programmable device of the present invention. As shown in FIG. 2 , the present invention is a method for fabricating a programmable device. The active region on the side of the capacitive transistor in the programmable device is pre-embedded and implanted with specific impurities, such as arsenic, before the gate oxide is formed.

[0011] The present invention pre-embeds and implants specific impurities in the active area on the capacitor side before forming the gate oxide, and can form a thicker oxide film in the active area on the capacitor side than the gate oxide film on the transistor side by adding only one implantation process step. membrane.

[0012] The present invention also has the following advantages: 1. The thickness of the oxide film can be increased without adding additional thermal oxidation, and the data storage time of the memory device can be improved; 2. The coupling efficiency is improved, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com